Silicon dielectric treating agent for use after etching, process for producing semiconductor device, and semiconductor device

A technology of post-treatment agent and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, semiconductor device, preparation of detergent mixture composition, etc., can solve problems such as increased dielectric constant and poor adhesion, and achieves improved Effects of manufacturing yield, suppression of increase in dielectric constant, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

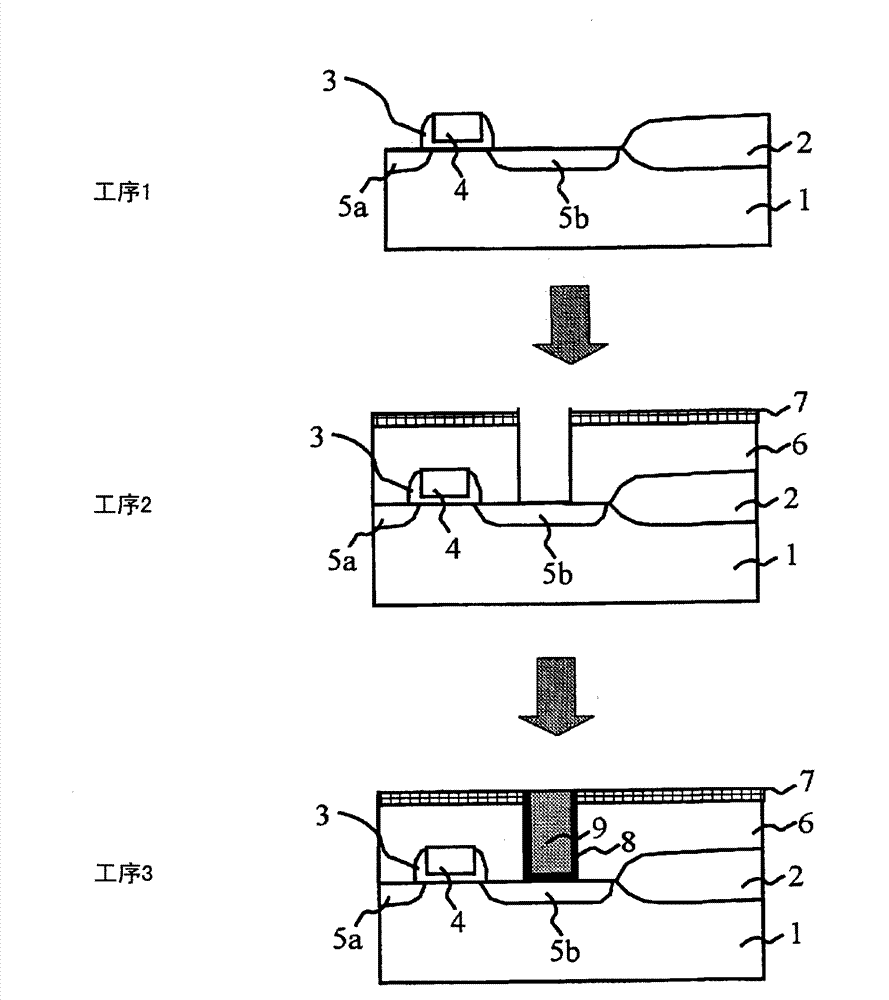

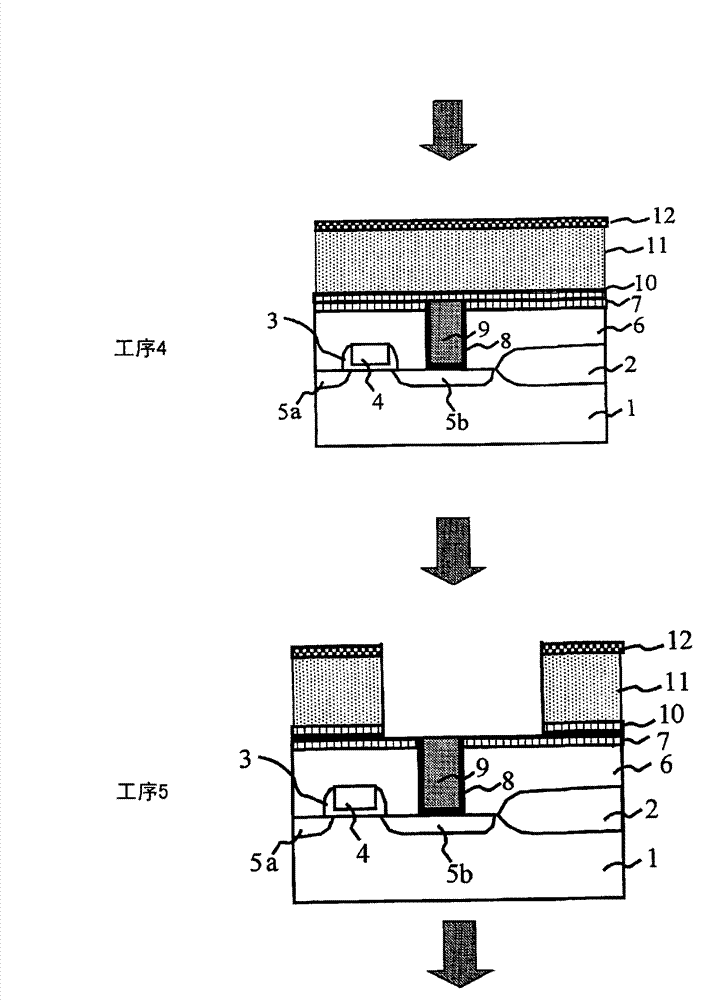

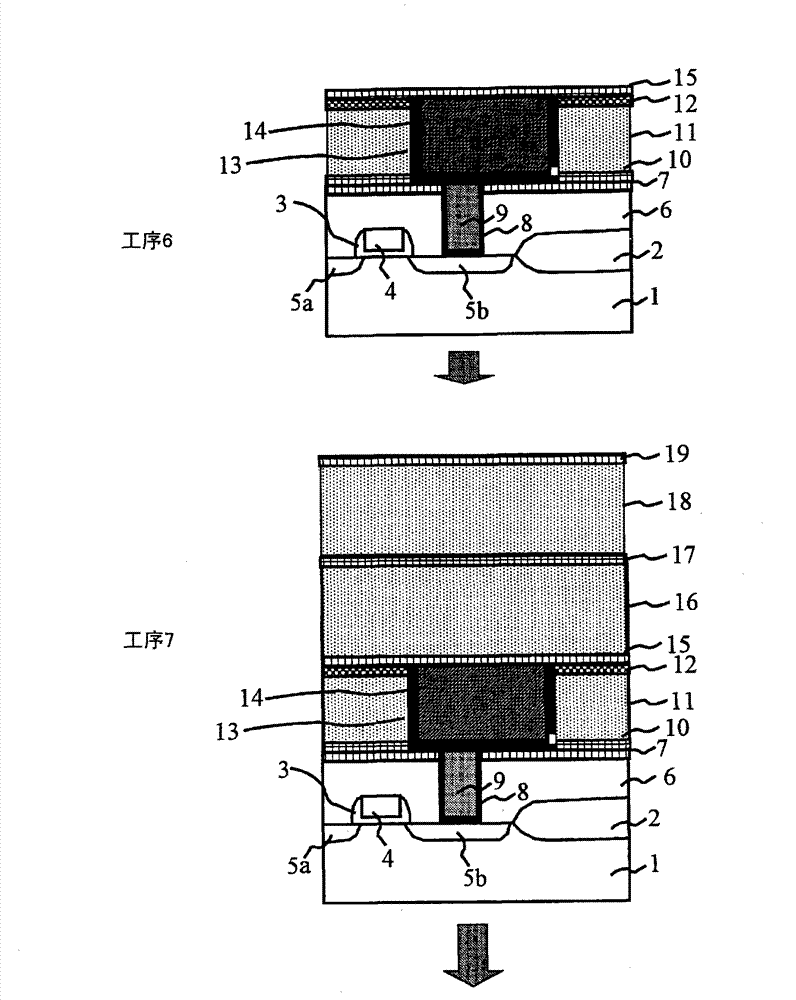

Method used

Image

Examples

Embodiment 1

[0120] Add 118g (1.0mol) of trimethylethoxysilane and 100g (1.66mol) of isopropanol into the reaction vessel, and at a constant temperature of 10°C, use a dropping funnel to add 1.0% by weight of A mixed solution of 17 g (0.01 mol) of ammonia water and 37 g (0.01 mol) of 1.0% by weight ammonium fluoride aqueous solution was dropped at a rate of 2 mL / min, and stirred for 2 hours after the drop was completed. The pH of the obtained solution (post-etching treatment agent) was measured with a pH meter, and the pH of the solution was 9.45.

Embodiment 2

[0122] Add 108 g (1.0 mol) of trimethylchlorosilane and 100 g (1.66 mol) of isopropanol into the reaction vessel, and at a constant temperature of 10° C., use a dropping funnel to add 17 g of 1.0% by weight of ammonia water described in Table 1 (0.01 mol) and 37 g (0.01 mol) of a 1.0% by weight ammonium fluoride aqueous solution were dropped at a rate of 2 mL / min, and stirred for 2 hours after the dropping was completed. The pH of the obtained solution was measured with a pH meter, and the pH of the solution (post-etching treatment agent) was 9.50.

Embodiment 3

[0124] 132g (1.0mol) of triethylsilanol and 150g (2.50mol) of isopropanol were added to the reaction vessel, and at a constant temperature of 10°C, 17g of 1.0% by weight of ammonia water described in Table 1 was added using a dropping funnel. (0.01 mol) and 37 g (0.01 mol) of a 1.0% by weight ammonium fluoride aqueous solution were dropped at a rate of 2 mL / min, and stirred for 2 hours after the drop was completed. The pH of the obtained solution was measured with a pH meter, and the pH of the solution (post-etching treatment agent) was 9.45.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com