Method for extracting linolenic acid from purslane

A technology of purslane and linolenic acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of sharp decline in provenance, neglect of seed retention, and reduction of purslane provenance, so as to reduce solvent The effect of reducing the loss, improving the extraction effect, and shortening the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A method for extracting linolenic acid from purslane, comprising the following steps: crushing dried purslane stems and leaves or one of them with a pulverizer to 50-200 mesh. Weigh 5.0g of the powder into a 250mL round bottom flask; add 100ml of organic solvent, and ultrasonically reflux for 4 hours under the condition of ultrasonic temperature of 40°C and ultrasonic power of 990W; The extract is the obtained linolenic acid mixture. The extract was concentrated under reduced pressure and dried to obtain a crude product of linolenic acid.

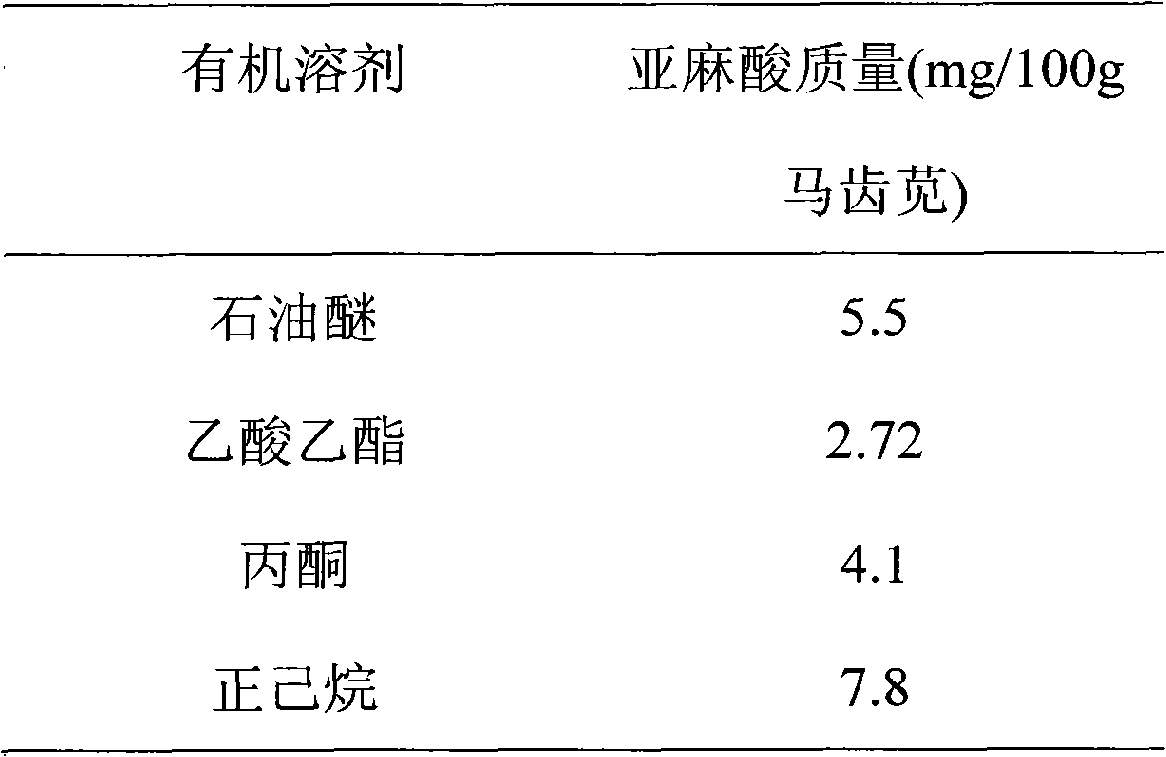

[0024] After the extract was concentrated by rotary evaporation, the remaining substance after concentration was dissolved with n-hexane and the volume was adjusted to 10 mL. The 10 mL sample was methylated and detected by reversed-phase high performance liquid chromatography. The results are shown in Table 1.

[0025] Table 1 The influence of different organic solvents on the extraction of linolenic acid

[0026] ...

Embodiment 2

[0027] Embodiment 2: A method for extracting linolenic acid from purslane, comprising the following steps: crushing dried purslane stems and leaves or one of them with a pulverizer to 50-200 mesh. Weigh 5.0g of the powder into a 250mL round bottom flask; add 50ml of organic solvent, and ultrasonically reflux for 2 hours under the condition of ultrasonic temperature of 50°C and ultrasonic power of 330W; The extract is the obtained linolenic acid mixture. The extract was concentrated under reduced pressure and dried to obtain a crude product of linolenic acid.

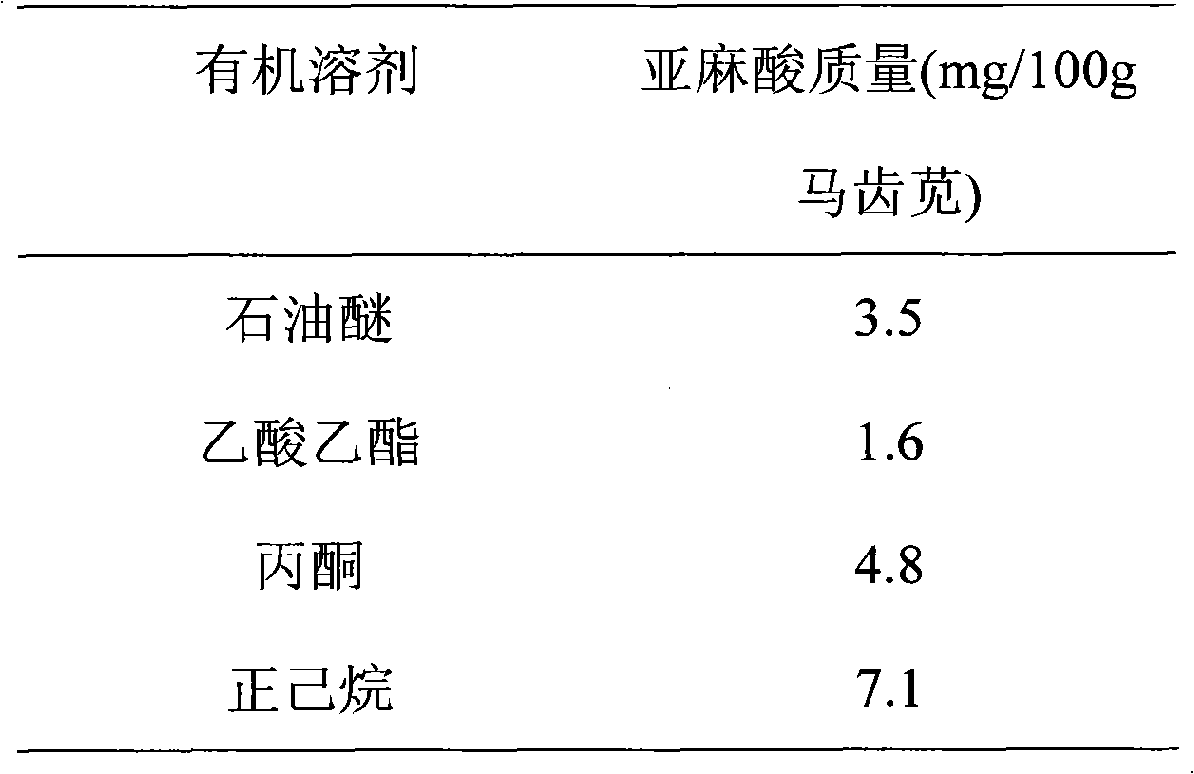

[0028] After the extract was concentrated by rotary evaporation, the remaining substance after concentration was dissolved with n-hexane and the volume was adjusted to 10mL. The 10mL sample was methylated and detected by reversed-phase high performance liquid chromatography. The results are shown in Table 2.

[0029] Table 2 Effect of different organic solvents on the extraction of linolenic acid

[0030]

Embodiment 3

[0031] Embodiment 3: A method for extracting linolenic acid from purslane, comprising the following steps: crushing dried purslane stems and leaves or one of them with a pulverizer to 50-200 mesh. Weigh 5.0g of the powder into a 250mL round bottom flask; add 25ml of organic solvent, and ultrasonically reflux for 0.5 hours under the conditions of ultrasonic temperature of 70°C and ultrasonic power of 220W; The extract is the obtained linolenic acid mixture. The extract was concentrated under reduced pressure and dried to obtain a crude product of linolenic acid.

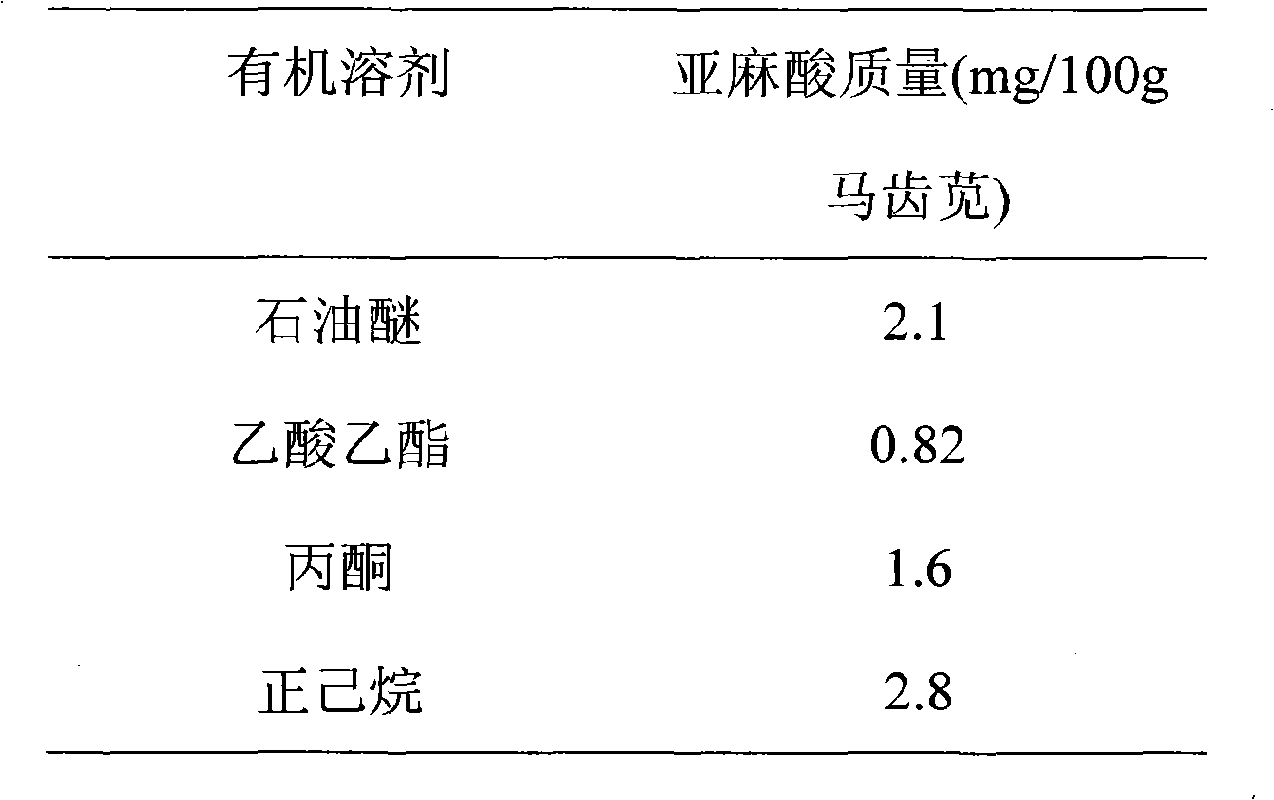

[0032] After the extract was concentrated by rotary evaporation, the remaining substance after concentration was dissolved with n-hexane and the volume was adjusted to 10 mL. The 10 mL sample was methylated and detected by reversed-phase high performance liquid chromatography. The results are shown in Table 3.

[0033] Table 3 The influence of different organic solvents on the extraction of linolenic acid

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com