Production method for converting sodium tartrate into tartaric acid

The technology of a sodium tartrate and a production method is applied in the separation/purification, chemical recovery, organic chemistry and other directions of carboxylic acid compounds, can solve problems such as low yield, high cost, complicated steps, etc., and achieves improved yield, transfer tank and Small size, stable product composition and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

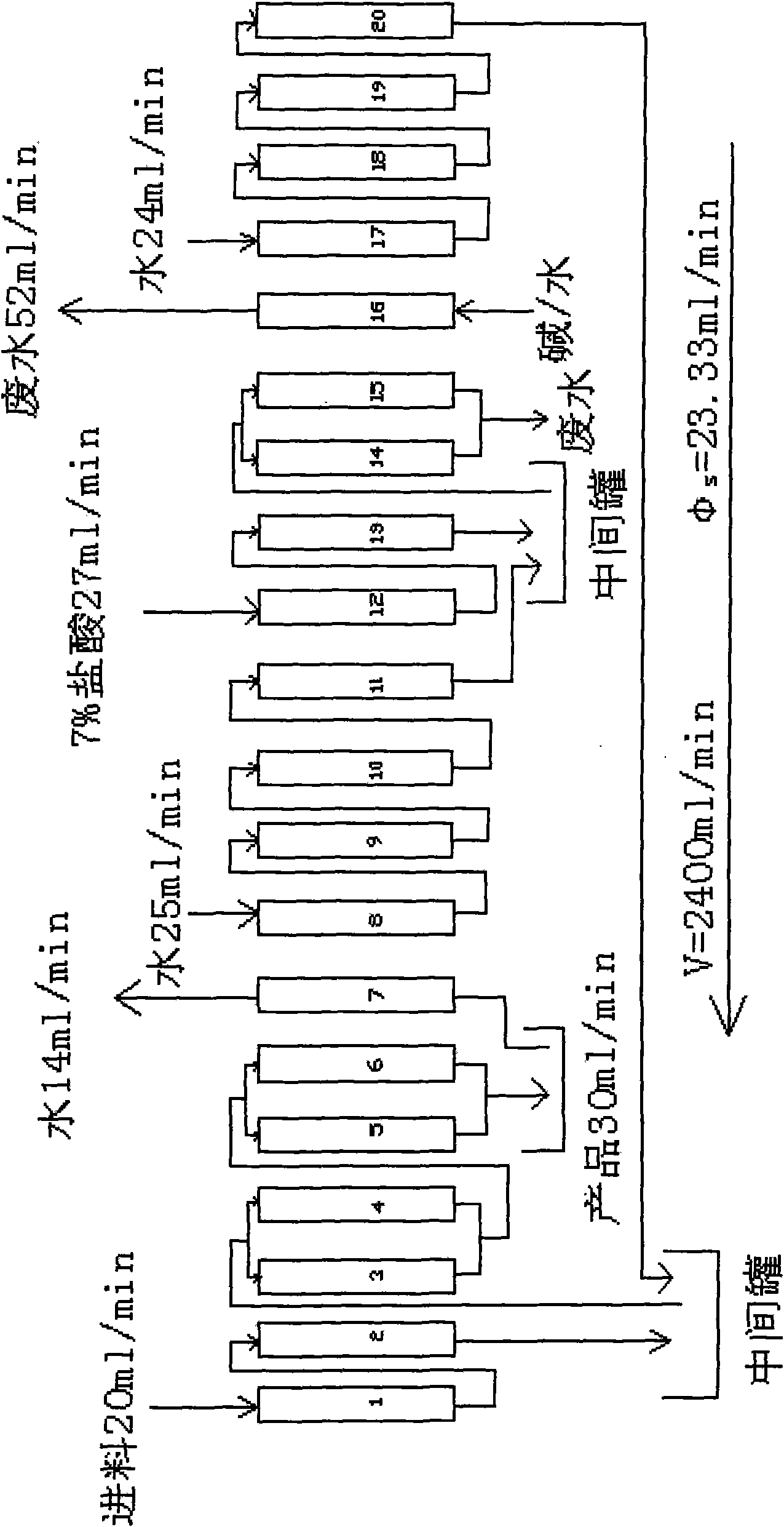

[0031] Combine below figure 1 And the embodiment is described in detail:

[0032] The present invention adopts the continuous fluid separation device independently developed by our company, adopts 732 strong acid cathodic resin, and the design processing capacity is 1.2L / H. According to the characteristics of sodium tartrate itself, the filling capacity of each resin is 200ml. Divided into the following sections:

[0033] (1) Product conversion zone (unit 1-6), wherein 1 and 2 are used as the sodium tartrate raw material liquid, wherein the 2 outlet liquid is mixed with the 20 outlet and then enters 3-6 together (two ports are connected in parallel and connected in series successively), and the feed liquid It is forward mode, and the feeding speed is 20ml / min;

[0034] (2) Convert the washing area (unit 17-20), adopt the single string positive feed mode, its outlet merges into 3 and 4 inlets, and the water inlet speed is 24ml / min;

[0035] (3) Regeneration zone (unit 12-15)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com