Methyl sulcotrione oil suspension concentrate combination

A technology of mesotrione and oil suspension, applied in the direction of herbicides, algicides, biocides, biocides, etc., can solve the problems of food competition and high prices, and achieve safe use, low price, and reduced use cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

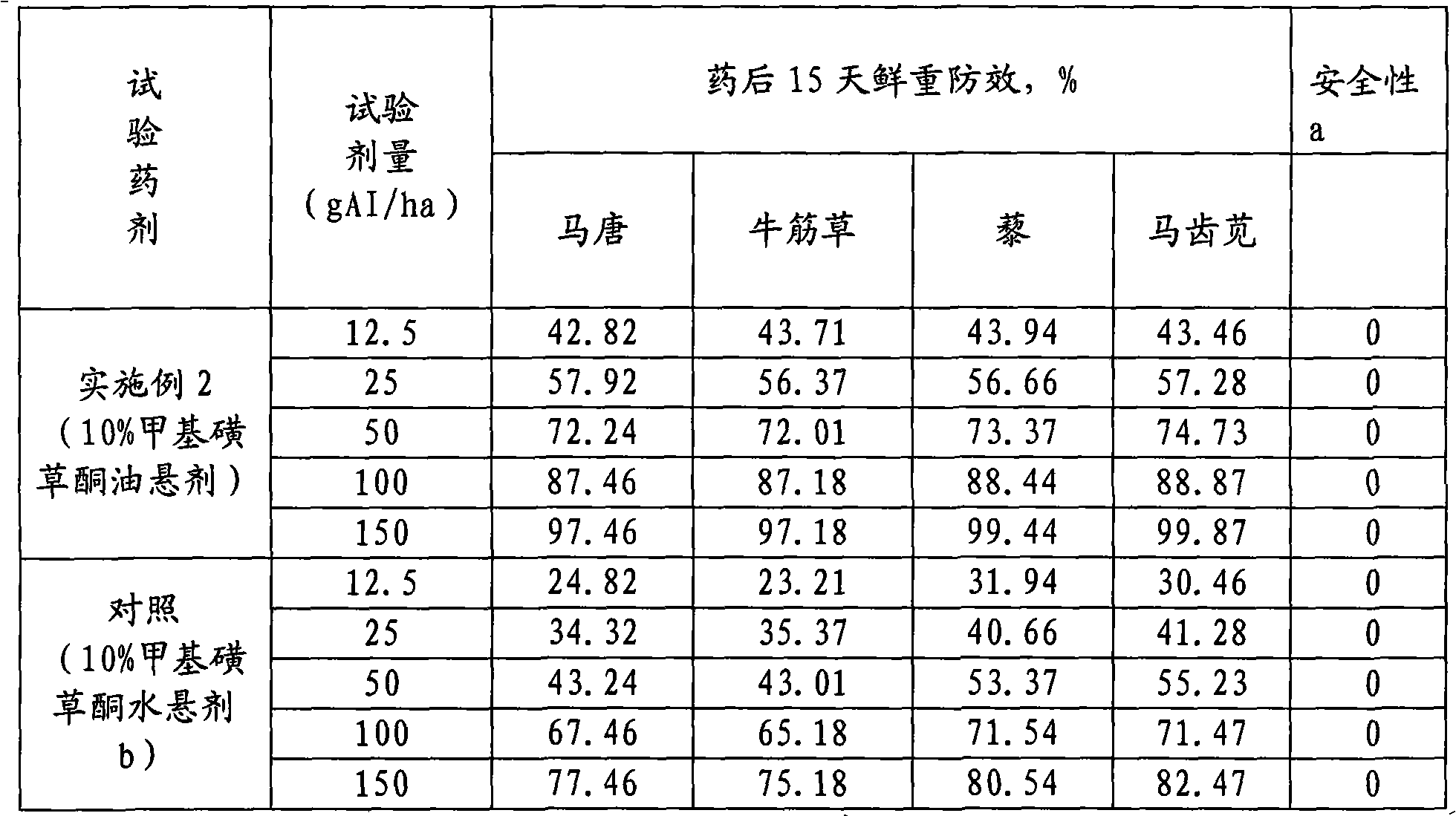

Examples

Embodiment 1

[0024] Mesotrione 52.63 kg, polyoxyethylene polyoxypropylene block copolymer 20 kg, polymer grafted lignosulfonate 30 kg, attapulgite 30 kg, glycerol 50 kg, modified polysiloxane 2 kg of alkane, 10 kg of 2,6-tert-butyl-p-cresol, 805.37 kg of jatropha oil

[0025] Preparation

[0026] 1 handful of mesotrione, polyoxyethylene polyoxypropylene block copolymer, attapulgite, modified polysiloxane, 2,6-tert-butyl p-cresol, jatropha oil (250 kg) Mixed in the sand mill;

[0027] 2 Sand grinding until the particle size of mesotrione is less than 4 μm;

[0028] 3 Transfer the sand-milled material to a homogeneous mixer, add polymer grafted lignosulfonate salt, glycerin, and jatropha oil (555.37 kg), and disperse homogeneously under the condition of 4000 rpm Mix evenly for 25 minutes, homogeneously disperse and mix evenly to obtain 1000 kg of 5% mesotrione oil suspension of the present invention, and the suspension rate detected by the GB / T14825 method is 94%.

Embodiment 2

[0030] Mesotrione 105.26 kg, fatty alcohol polyoxyethylene ether 20 kg, polymer grafted lignosulfonate 20 kg, polycarboxylate 20 kg, attapulgite 20 kg, glycerin 40 kg, modified poly 1 kg of siloxane, 773.64 kg of jatropha oil methyl ester

[0031] Preparation

[0032] 1. Mix the former medicine of mesotrione, fatty alcohol polyoxyethylene ether, attapulgite, modified polysiloxane, and jatropha oil methyl ester (300 kilograms) in a sand mill;

[0033] 2 Sand grinding until the particle size of mesotrione is less than 4 μm;

[0034] 3. Transport the sand-milled material to a homogeneous mixer, add polymer grafted lignosulfonate, glycerol, polycarboxylate, jatropha oil methyl ester (473.64 kg), and mix at 10,000 rpm Homogeneously disperse and mix uniformly for 25 minutes to obtain 1000 kilograms of 10% mesotrione oil suspension of the present invention, and the suspension rate detected by GB / T14825 method is 95%.

Embodiment 3

[0036] Mesotrione 105.26 kg, polyoxyethylene alkyl ester 15 kg, naphthalene and alkylnaphthalene sulfonate formaldehyde condensate 50 kg, bentonite 15 kg, glycerol 30 kg, 2,6-tert-butyl p- 10 kg of cresol, 2 kg of modified polysiloxane, 772.74 kg of jatropha oil

[0037] Preparation

[0038] 1 Mix the original drug of mesotrione, polyoxyethylene alkyl ester, bentonite, modified polysiloxane, 2,6-tert-butyl p-cresol, Jatropha oil (300 kg) in a sand mill middle;

[0039] 2 Sand grinding until the particle size of mesotrione is less than 4 μm;

[0040] 3 Transfer the sand-milled material to a homogeneous mixer, add naphthalene and alkylnaphthalene sulfonate formaldehyde condensate, glycerol, jatropha oil (472.74 kg), and homogenize under the condition of 6000 rpm Disperse and mix uniformly for 30 minutes and homogeneously disperse and mix uniformly to obtain 1000 kg of 10% mesotrione oil suspension of the present invention, and the suspension rate detected by the GB / T14825 met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com