Metal laminated plate and preparation method thereof

A technology of laminates and metal layers, which is applied in the field of metal laminates for flexible printed circuits and its preparation, can solve the problems of poor adhesive performance between resin and metal foil, decreased thermal dimensional stability, and obvious hygroscopic expansion effect. The effect of achieving excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

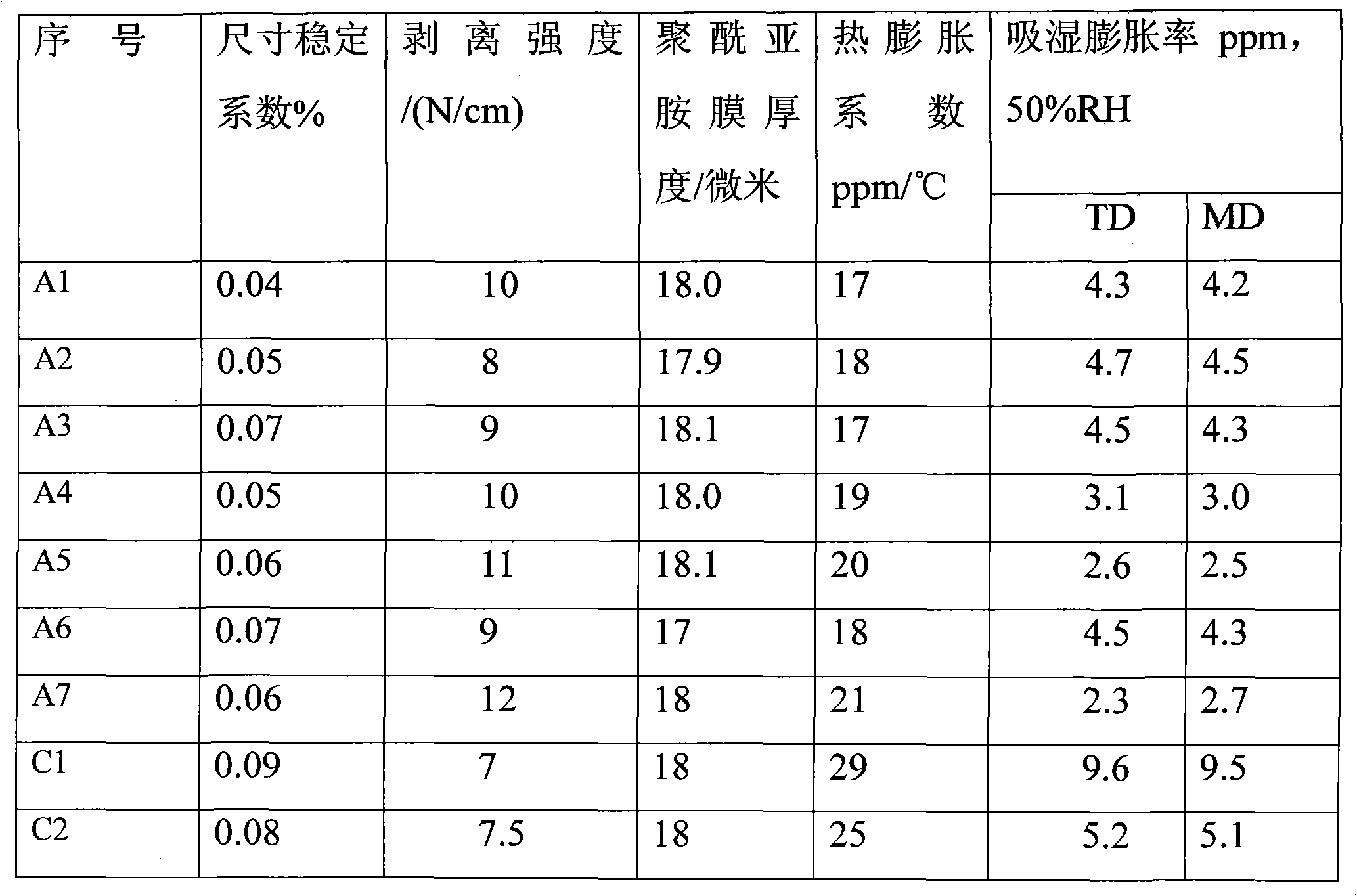

Examples

Embodiment approach

[0035] According to a preferred embodiment of the present invention, the preparation method of the metal laminate provided by the present invention comprises the following steps:

[0036] (1) Add aromatic tetra-acid dianhydride and aromatic diamine into the solvent according to the molar ratio of 0.9-1.2:0.9-1.2, the amount of the solvent makes the concentration of the obtained polyamic acid 5-40% by weight, After stirring and reacting at 20-70°C for 3-15 hours, vacuum degassing at the same temperature for 1-12 hours to obtain a polyamic acid solution, wherein the aromatic diamines are biphenylenediamine, p-phenylenediamine, 4,4 '-diaminodiphenyl ether;

[0037] (2) At a temperature of 10-40°C and a relative humidity of 20-80%, the above polyamic acid solution is coated on a copper foil, dried at 20-200°C, and the solvent is removed to obtain a 5-50 micron polyamic acid film;

[0038] (3) For the above-mentioned copper foil covered with polyamic acid solution, the method of ...

Embodiment 1

[0053] With the pyromellitic dianhydride of 74.9g, the 4 of 13.75g, the 4'-diaminobiphenyl, the p-phenylenediamine of 12.65g, the 4 of 13.75g, the 4'-diaminodiphenyl ether (the molar ratio is 1.0 : 0.2: 0.6: 0.2) according to adding 1030g solvent is N, N-dimethylacetamide mixes, and temperature is controlled at 20 ℃, and the time is 9 hours, obtains the polyamide that solid content is 12%, viscosity is 25000cp acid solution.

[0054] Filter the obtained polyamic acid solution, and vacuum degassing for 2 hours under the condition of a vacuum degree of 0.003 MPa. (Model QTG, Tianjin Jingke Material Testing Machine Factory) Coated on a copper foil with a size of 300×250×18 microns and a roughness of 0.6 microns, put it in an oven, and carried out segmentation under the condition of nitrogen atmosphere imidization by heating. Among them, the heating temperature of the first section is 70°C and the time is 10 minutes, the heating temperature of the second section is 150°C and the...

Embodiment 2

[0056] This embodiment is used to illustrate the metal laminate provided by the present invention and its preparation method.

[0057] 83.71g of 3,3',4,4'-biphenyltetracarboxylic dianhydride, 15.73g of 4,4'-diaminobiphenyl, 18.46g of p-phenylenediamine, 5.7g of 4,4'- Diaminodiphenyl ether (molar ratio is 1.2: 0.3: 0.6: 0.1) is added to 1030g solvent as N, N-dimethylacetamide and mixed, the temperature is controlled at 25°C, and the time is 9 hours to obtain the solid content 12% polyamic acid solution with a viscosity of 35000ccp.

[0058] Filter the obtained polyamic acid solution, and vacuum degassing for 2 hours under the condition of a vacuum degree of 0.003 MPa. (Model QTG, Tianjin Jingke Material Testing Machine Factory) coated on a copper foil with a thickness of 18 microns and a roughness of 0.6 microns, put it in an oven, and heat the acrylic acid in sections under a nitrogen atmosphere. Amination. Among them, the heating temperature of the first section is 70°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com