Carbon fiber whisker reinforced contact net lead and preparation method thereof

A catenary and carbon fiber technology, applied in the direction of overhead lines, metal rolling, liquid chemical plating, etc., can solve the problems of large temperature difference changes, low tensile strength of catenary wires, poor arc resistance, etc., and achieve elastic modulus Large, light weight, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

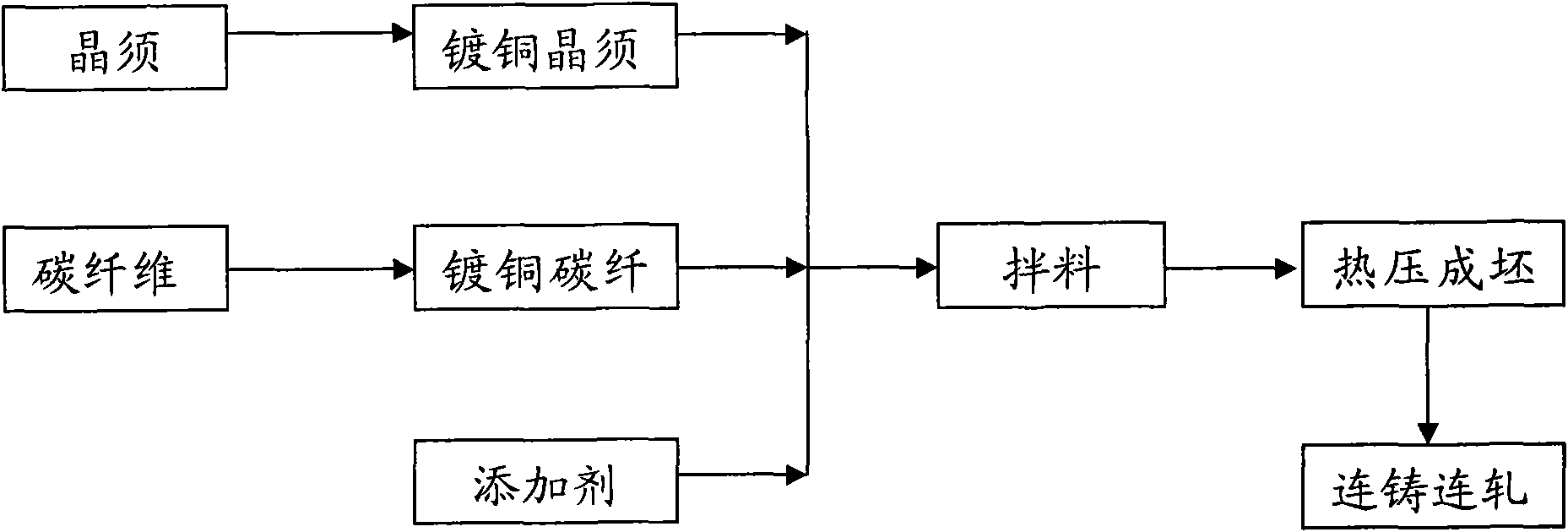

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] The invention provides a carbon fiber whisker-reinforced catenary wire, aimed at the existing aluminum-clad steel, copper-clad steel, silver-copper alloy or pure copper contact wires with low tensile strength, small elastic modulus, poor arc resistance, thermal expansion Significant improvements have been made to solve the problem that the cold shrinkage coefficient is large and cannot meet the technical requirements for current intake of electric locomotives on high-speed electrified railways. The tensile strength of carbon fiber is more than 8-10 times that of ordinary steel, and the modulus of elasticity is better than that of steel, with excellent creep resistance, corrosion resistance and shock resistance; carbon fiber is light in weight, only 1 / 5 of st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap