A kind of preparation method and application of EPDM graft copolymer

A technology of EPDM rubber and graft copolymer is applied in the field of preparation of graft copolymer to achieve the effects of improving the conversion rate of monomers, stabilizing the polymerization reaction process and improving compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

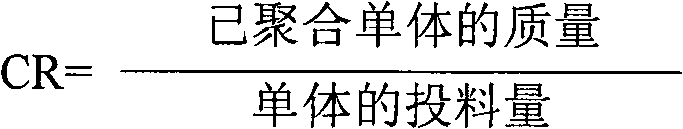

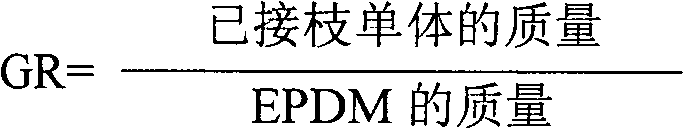

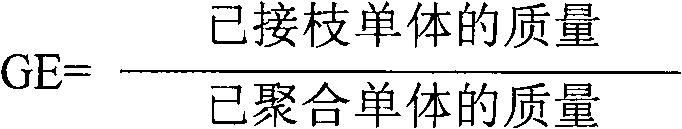

[0035] Embodiment 1 provides the impact of the different ratios of AN / MMA on the CR, GR and GE of the product EPDM-g-MAN and the impact strength of the AEMS notch, wherein the reaction formula is as shown in Table 1, the reaction product EPDM-g-MAN and The performance of AEMS is shown in Table 2.

Embodiment 2

[0036] Embodiment 2 provides the impact of the different mass ratios of EPDM and graft monomer (MMA-AN) on the CR, GR and GE of product EPDM-g-MAN and the impact strength of AEMS notch, wherein the reaction formula is as shown in table 3, The properties of the reaction products EPDM-g-MAN and AEMS are shown in Table 4.

Embodiment 3

[0037] Embodiment 3 provides the impact of the different dosages of BPO on the CR, GR and GE of the product EPDM-g-MAN and the notched impact strength of AEMS, wherein the reaction formula is as shown in Table 5, and the performance of the reaction product EPDM-g-MAN and AEMS As shown in Table 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com