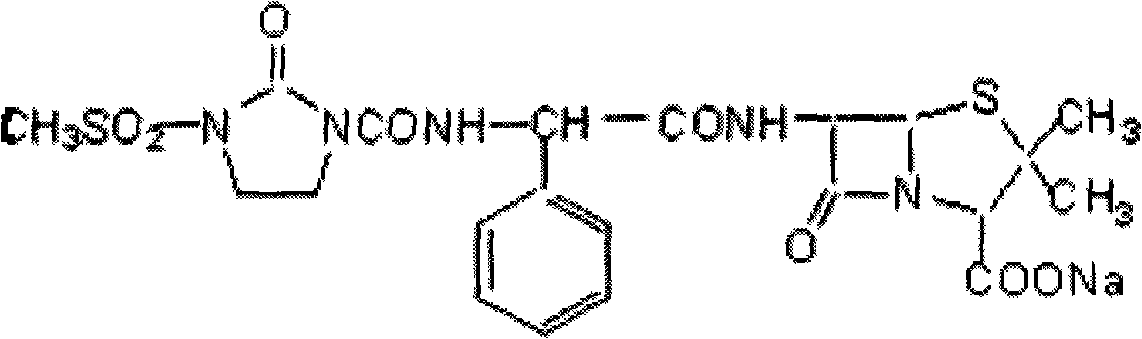

Method for synthesizing mezlocillin sodium through solvent method

A technology of mezlocillin sodium and mezlocillin acid, applied in the direction of organic chemistry and the like, achieves the effects of good stability, fast water dissolving speed and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A salt-forming agent: Dissolve 3.5g of sodium isooctanoate in a mixed solvent of 25ml of isopropyl ether and 5ml of acetone, add 0.1g of activated carbon, stir for 30min to decolorize, and filter through micropores;

[0027] B mezlocillin acid solution: dissolve 10 g of mezlocillin acid in 30 ml of acetone, add 0.3 g of activated carbon, stir for decolorization for 30 min, and filter through micropores;

[0028] C acetone: 10ml microporous filter;

[0029] Slowly add salt-forming agent A and mezlocillin acid solution B into the reaction vessel containing C at the same time at 20°C, control the rate of addition to 0.4ml / min, add about 1 / 3 of the solution, crystallize and grow the crystal for 1 hour, then Carry out the second simultaneous dropwise addition at the same speed, stir and grow the crystal for 2 hours after the drop, cool down at 3°C and filter with suction, wash with 5ml of isopropyl ether, vacuum-0.08Mpa, and vacuum-dry at 40°C for 3h to obtain mezlocillin ...

Embodiment 2

[0032] A salt-forming agent: Dissolve 3.3g of sodium isooctanoate in a mixed solvent of 25ml of isopropyl ether and 10ml of acetone, add 0.1g of activated carbon, stir for 30min to decolorize, and filter through micropores;

[0033] B mezlocillin acid solution: dissolve 10 g of mezlocillin acid in 30 ml of acetone, add 0.3 g of activated carbon, stir for decolorization for 30 min, and filter through micropores;

[0034] C Acetone: 5ml is filtered through microporous;

[0035] Slowly add salt-forming agent A and mezlocillin acid solution B into the reaction container containing C at the same time at 25°C, control the rate of addition to 0.4ml / min, add about 1 / 3 of the solution, crystallize and grow the crystal for 1 hour, then Carry out the second simultaneous dropwise addition at the same speed, stir and grow crystals for 2 hours after dropping, cool down at 5°C and filter with suction, wash with 5ml of isopropyl ether, vacuum-0.09Mpa, and vacuum-dry at 45°C for 4h to obtain m...

Embodiment 3

[0038] A salt-forming agent: Dissolve 3.2g of sodium isooctanoate in a mixed solvent of 20ml of isopropyl ether and 10ml of acetone, add 0.1g of activated carbon, stir for 30min to decolorize, and filter through micropores;

[0039] B mezlocillin acid solution: dissolve 10 g of mezlocillin acid in 30 ml of acetone, add 0.3 g of activated carbon, stir for decolorization for 30 min, and filter through micropores;

[0040] C acetone 5ml and isopropyl ether 5ml mixed solvent are filtered through microporous;

[0041] Slowly add salt-forming agent A and mezlocillin acid solution B into the reaction container containing C at the same time at 25°C, control the rate of addition to 0.4ml / min, add about 1 / 3 of the solution, crystallize and grow the crystal for 1 hour, then Carry out the second simultaneous dropwise addition at the same speed, stir and grow crystals for 2 hours after dropping, cool down at 3°C and filter with suction, wash with 5ml of isopropyl ether, vacuum-0.085Mpa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com