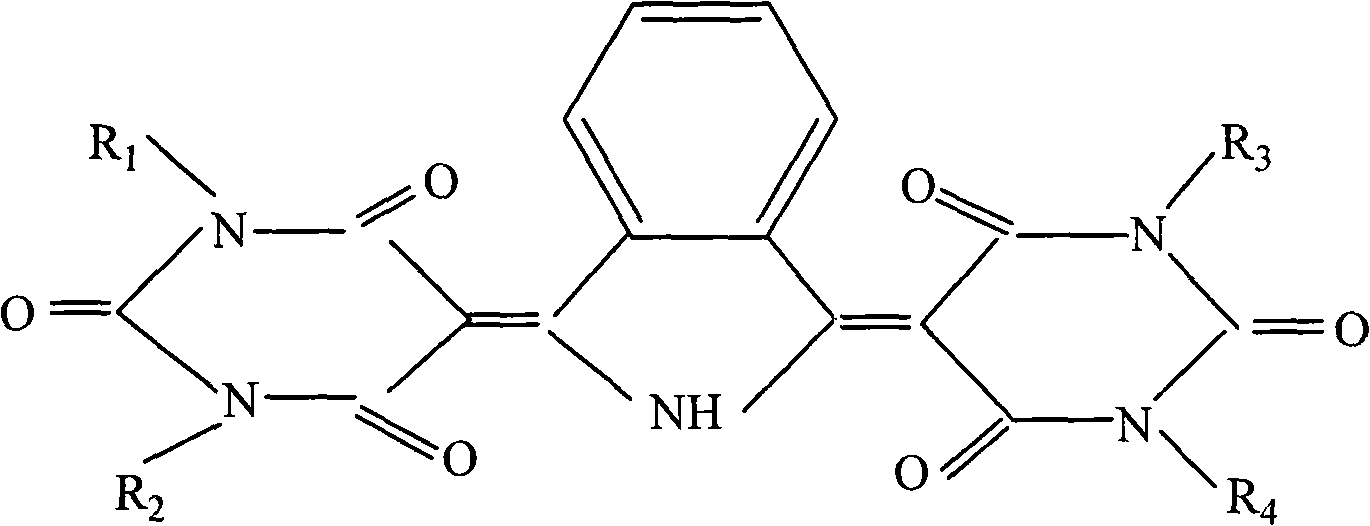

Method for preparing isoindoline pigment

An isoindoline and pigment technology, which is applied in the field of preparation of isoindoline pigments, can solve the problems of poor heat resistance, light resistance, oxidation resistance and easy dispersibility, poor color light and tinting strength, low pigment yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1. Synthesis of pigments: In a 500ml four-neck bottle equipped with a reflux condenser and a thermometer, add 110g of formic acid and 10.24g (0.08mol) of barbituric acid, stir to form a suspension, and 1,3-diiminoisoind Add 5.8g (0.04mol) of indoline in 30 minutes, react at room temperature for 1h, adjust the pH value of the medium to 1.0, raise the temperature to 70°C and react for 3h, add 0.2g of 2,6-di-tert-butyl-p-cresol, continue to heat up to reflux, Reflux for 5 hours, filter with suction, recover the filtrate for reuse, and use the filter cake for later use.

[0015] 2. Configuration of surfactant solution: accurately weigh C 12-18 Add 0.28g of fatty alcohol polyoxyethylene ether (20) ether and 0.28g of SOLSPERSE 27000 into 5g of water, heat to dissolve and set aside.

[0016] 3. Pigmentation: Add 450g of water, pigment filter cake (25% solid content) and surfactant solution into a beaker, stir and dissolve, add 5% sodium hydroxide solution, adjust pH=5, heat u...

Embodiment 2

[0018] 1. Synthesis of pigments: In a 500ml four-necked bottle equipped with a reflux condenser and a thermometer, add 120g of formic acid and 12.5g (0.08mol) of N, N-dimethylbarbituric acid, and stir to form a suspension, 1, Add 5.8 g (0.04 mol) of 3-diiminoisoindoline in 30 minutes, react at room temperature for 1 hour, adjust the pH value of the medium to 1.0, raise the temperature to 80°C for 3 hours, add 0.2 g, continue to heat up to reflux, reflux reaction for 5h, suction filtration, recycle the filtrate, and use the filter cake for later use.

[0019] 2. Configuration of surfactant solution: accurately weigh C 12-18 Add 0.28g of fatty alcohol polyoxyethylene ether (20) ether and 0.28g of SOLSPERSE 27000 into 5g of water, heat to dissolve and set aside.

[0020] 3. Pigmentation: Add 450g of water, pigment filter cake (25% solid content) and surfactant solution into a beaker, stir and dissolve, add 5% sodium hydroxide solution, adjust pH=4.5, heat up to 100°C, Insulate ...

Embodiment 3

[0022] Same as Example 1, only use 5% sodium carbonate solution instead of 5% sodium hydroxide solution to obtain a yellowish pigment with a greener color than Example 1 when pigmenting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com