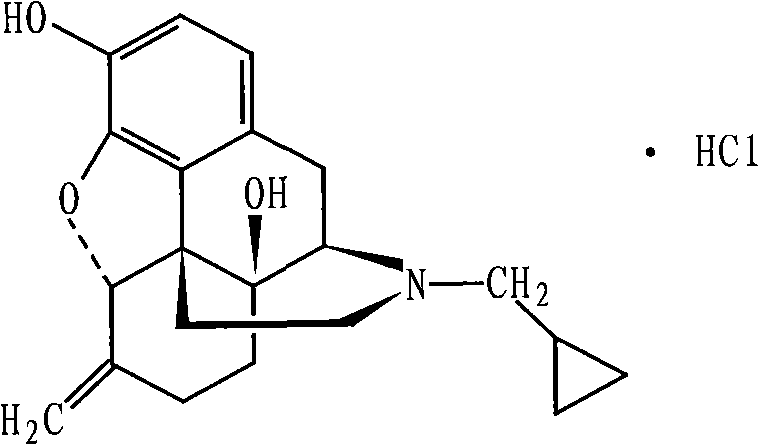

Nalmefene hydrochloride injection and preparation method thereof

A technology of nalmefene and injection, which is applied in the field of nalmefene hydrochloride injection and its preparation, can solve problems such as safety, effectiveness risk, and inability to achieve stable effects, and achieve the effect of improving stability and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

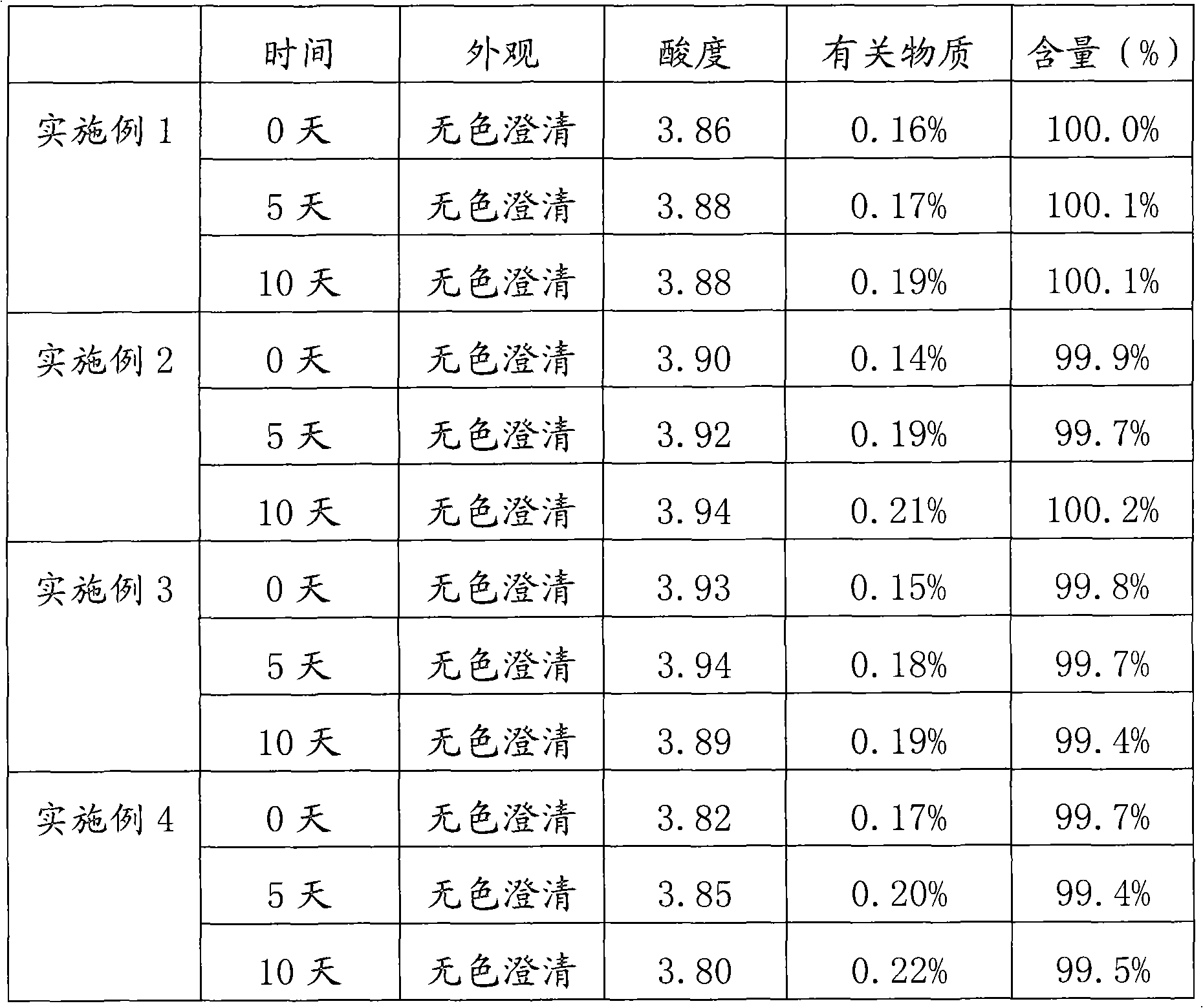

Embodiment 1

[0024] Embodiment 1: This embodiment prepares 1000 nalmefene hydrochloride injections (specification: 1ml: 0.1mg),

[0025] Use the following ingredients:

[0026] Material name Feed amount

[0027] Nalmefene Hydrochloride 0.1108g (equivalent to Nalmefene 0.1g)

[0029] tert-butylhydroxyanisole (BHA) 15mg

[0030] Add water for injection to 1000ml

[0031] Process steps: Take 15 mg of butyl hydroxyanisole (BHA) and 9 g of sodium chloride and add them to water for injection. After dissolving, adjust the pH to 3.8 with hydrochloric acid, add water for injection to 1000 ml, add 1.0 g of activated carbon, and decolorize at room temperature for 30 minutes After the decolorization is completed, filter with a 0.22 μm filter membrane, add 0.1108 g of nalmefene hydrochloride to the filtrate, stir and dissolve, filter with a 0.22 μm filter membrane, fill with nitrogen, and sterilize at 121 ° C for 20 minutes to obtain Nalmefene hydrochloride Fen injectio...

Embodiment 2

[0032] Embodiment 2: This embodiment prepares 1000 nalmefene hydrochloride injections (specification: 1ml: 0.1mg),

[0033] Use the following ingredients:

[0034] Material name Feed amount

[0035] Nalmefene Hydrochloride 0.1108g (equivalent to Nalmefene 0.1g)

[0037] 2,6-di-tert-butyl-4-hydroxy-phenol (BHT) 60mg

[0038] Add water for injection to 1000ml

[0039] Process steps: Add 60mg of 2,6-di-tertiary hydroxy-p-cresol (BHT) and 9g of sodium chloride into water for injection, after dissolving, adjust the pH to 3.8 with hydrochloric acid, add water for injection to 1000ml, and add 1.0g of activated carbon , decolorize at room temperature for 30 minutes, filter with a 0.22 μm filter membrane after decolorization, add 0.1108 g of nalmefene hydrochloride to the filtrate, stir to dissolve, filter with a 0.22 μm filter membrane, fill with nitrogen, and sterilize with damp heat at 121°C for 20 minutes , to obtain nalmefene hydrochloride injectio...

Embodiment 3

[0040] Embodiment 3: This embodiment prepares 1000 nalmefene hydrochloride injections (specification: 1ml: 0.1mg), using the following ingredients:

[0041] Material name Feed amount

[0042] Nalmefene Hydrochloride 0.1108g (equivalent to Nalmefene 0.1g)

[0043] Sodium chloride 9g

[0044] Rosemary 20mg

[0045] Add water for injection to 1000ml

[0046] Process steps: Take 20mg of rosemary and 9g of sodium chloride and add them to water for injection. After dissolving, adjust the pH to 3.8 with hydrochloric acid, add water for injection to 1000ml, add 1.0g of activated carbon, and decolorize at room temperature for 30 minutes. Filter through a 0.22 μm filter, add 0.1108 g of nalmefene hydrochloride to the filtrate, stir to dissolve, filter with a 0.22 μm filter, fill with nitrogen and seal, and sterilize with damp heat at 121° C. for 20 minutes to obtain nalmefene hydrochloride injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com