Preparation method of copper-zinc-tin-sulfur nano particles

A nanoparticle, copper-zinc-tin-sulfur technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as harsh reaction conditions, achieve the effect of simple equipment requirements and avoid expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

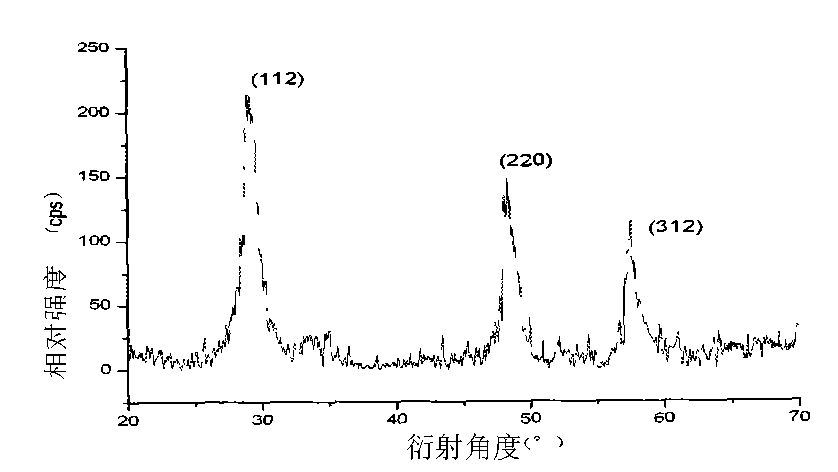

[0027] Add 0.25mmol zinc chloride, 0.25mmol tin dichloride, 0.5mmol copper acetate, 1mmol sulfur powder into the reaction tube, add 1.25mmol oleylamine, heat treatment at 100°C for 24 hours, dissolve the obtained product in ethanol, and centrifuge at 8000rpm For 10 minutes, remove the lower layer of precipitate, add chloroform, centrifuge at 7000rpm for 5 minutes, take the supernatant, add 0.1ml oleylamine and 2.5ml of ethanol, centrifuge at 8000rpm for 10 minutes, remove the lower layer of precipitate, evaporate the solvent to obtain copper zinc tin sulfur Nanoparticles, copper-zinc-tin-sulfur nanoparticles have a diameter of 5nm, and the X-ray diffraction pattern of the final product is as follows figure 1 .

Embodiment 2

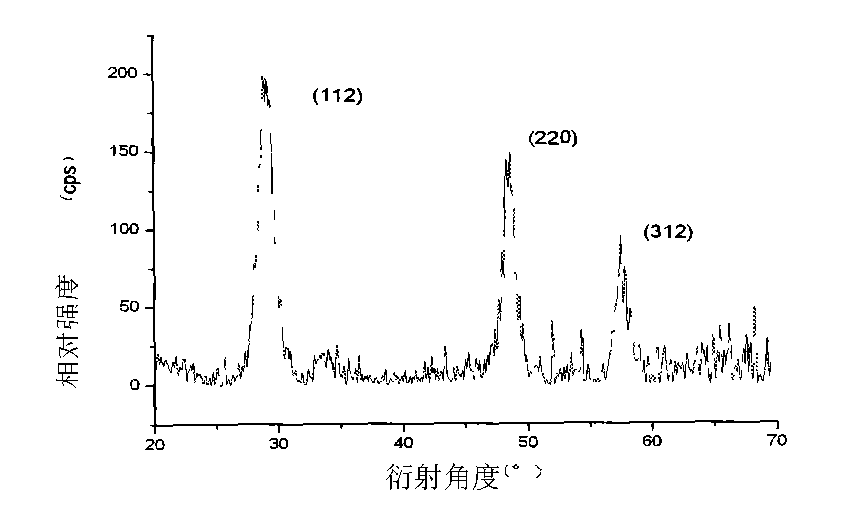

[0029] Add 0.3mmol of zinc sulfate, 0.3mmol of tin acetate, 0.5mmol of cuprous cyanide, and 4.4mmol of sulfur powder into the reaction tube, add 15mmol of oleylamine, heat at 350°C for 10 hours, and dissolve the obtained product in 3.8ml of ethylene glycol. Centrifuge at 8000rpm for 10 minutes, remove the lower precipitate, add 2.5ml tetrachlorethylene, centrifuge at 7000rpm for 5 minutes, take the supernatant, add 0.1ml oleylamine and 2.5ml ethylene glycol, centrifuge at 8000rpm for 10min, remove the lower layer, evaporate Obtain copper-zinc-tin-sulfur nanoparticles after the solvent is dried, and the diameter of the copper-zinc-tin-sulfur nanoparticles is 8nm, and the X-ray diffraction pattern of the final product is as follows: figure 2 .

Embodiment 3

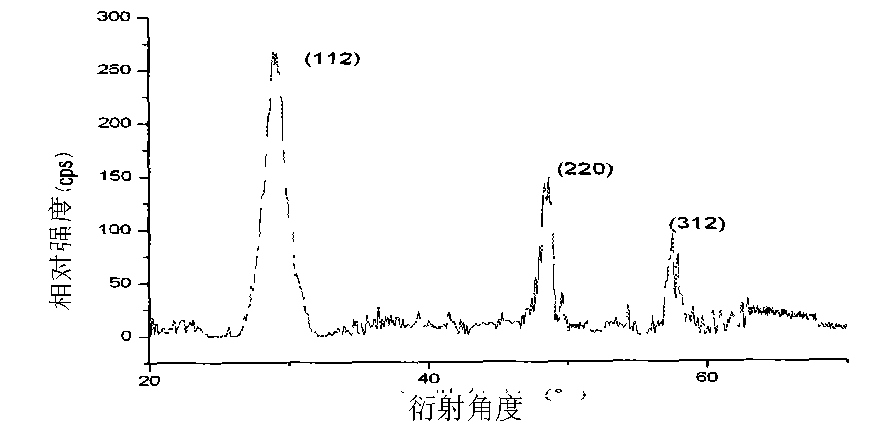

[0031] Add 0.3mmol of zinc acetate, 0.28mmol of tin dichloride, 0.5mmol of cuprous chloride, and 1.5mmol of sulfur powder into the reaction tube, add 6mmol of oleylamine, heat at 500°C for 1 hour, and dissolve the obtained product in 2.85ml of ethylene dichloride Alcohol, centrifuge at 8000rpm for 10 minutes, remove the lower layer of precipitate, add 2.5ml of n-hexane, centrifuge at 7000rpm for 5 minutes, take the supernatant, add 0.1ml of oleylamine and 2.5ml of ethylene glycol, centrifuge at 8000rpm for 10 cuprous chloride Remove the lower layer of precipitation, evaporate the solvent to obtain copper zinc tin sulfur nanoparticles, the diameter of the copper zinc tin sulfur nanoparticles is 9nm, and the X-ray diffraction pattern of the final product is as follows: image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com