Infrared radiation composite radiating coating and preparation method and spraying method thereof

A technology of infrared radiation and heat-dissipating coatings, applied in epoxy resin coatings, devices for coating liquid on surfaces, coatings, etc., can solve the problems of high cost, easy to rust, complex structure, etc. temperature, the effect of solving heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] An infrared radiation composite heat-dissipating coating composition, the composition consists of 58-80 parts of epoxy resin or B133 acrylic resin, 12-24 parts of nano silicon dioxide, 8-18 parts of 2-propylene Base-polyaniline nanofiber, 20 parts~50 parts of solvents form, and above-mentioned said solvent refers to xylene, methyl isobutyl ketone, n-butanol, wherein the mass ratio of three kinds of substances is xylene: methyl isobutyl ketone : n-butanol=18~23:1~5:1~4.

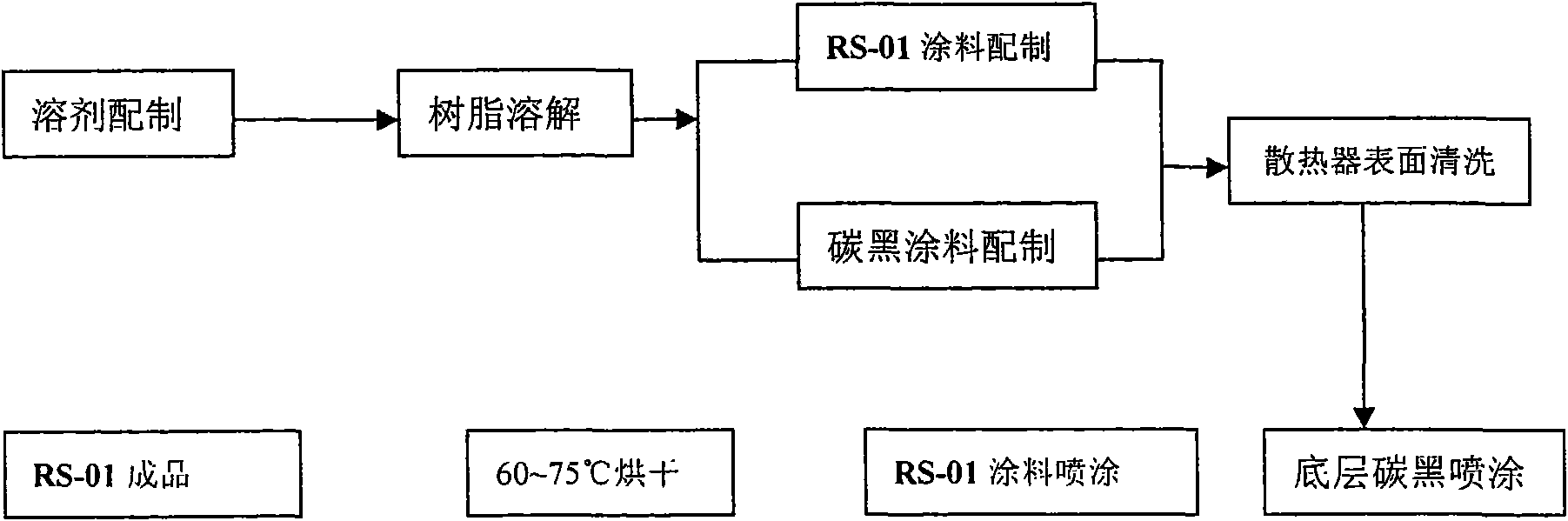

[0053]A preparation method of an infrared radiation composite heat-dissipating coating composition is carried out according to the following steps:

[0054] 1) Preparation of connecting material:

[0055] ①Solvent preparation:

[0056] Take xylene by mass ratio, methyl isobutyl ketone, n-butanol, its xylene: methyl isobutyl ketone: n-butanol=18~23: 1~5: 1~4, stir evenly with glass rod;

[0057] ② Dissolution of resin

[0058] Weigh epoxy resin or B133 acrylic resin according to the mass ratio, add i...

Embodiment 2

[0075] Infrared radiation composite heat-dissipating coating composition, composed of 60 to 75 parts of epoxy resin or B133 acrylic resin, 14 to 22 parts of nano silicon dioxide, and 9 to 16 parts of 2-propenyl-polyaniline in mass ratio Nanofibers, composed of 22 parts to 48 parts of solvent, said solvent refers to xylene, methyl isobutyl ketone, and n-butanol, and the mass ratio of the three substances is xylene: methyl isobutyl ketone: n-butyl Alcohol=19~22: 2~4: 2~3, the preparation of coating and spraying method are with embodiment 1.

Embodiment 3

[0077] Infrared radiation composite heat-dissipating coating composition, composed of 65 to 70 parts of epoxy resin or B133 acrylic resin, 16 to 20 parts of nano silicon dioxide, and 11 to 18 parts of 2-propenyl-polyaniline according to the mass ratio Nanofibers, composed of 25 parts to 45 parts of solvent, the solvent mentioned above refers to xylene, methyl isobutyl ketone, and n-butanol, and the mass ratio of the three substances is xylene: methyl isobutyl ketone: n-butyl Alcohol=20~21: 2.5~3.5: 3~4, the preparation of coating and spraying method are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com