Waste water treatment method in 1-naphthylamine-4-sodium sulfonate production process

A production process and wastewater treatment technology, which is applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve problems such as environmental pollution, re-pollution, and expensive treatment costs, and reduce production costs. The effect of cost, solving pollution and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

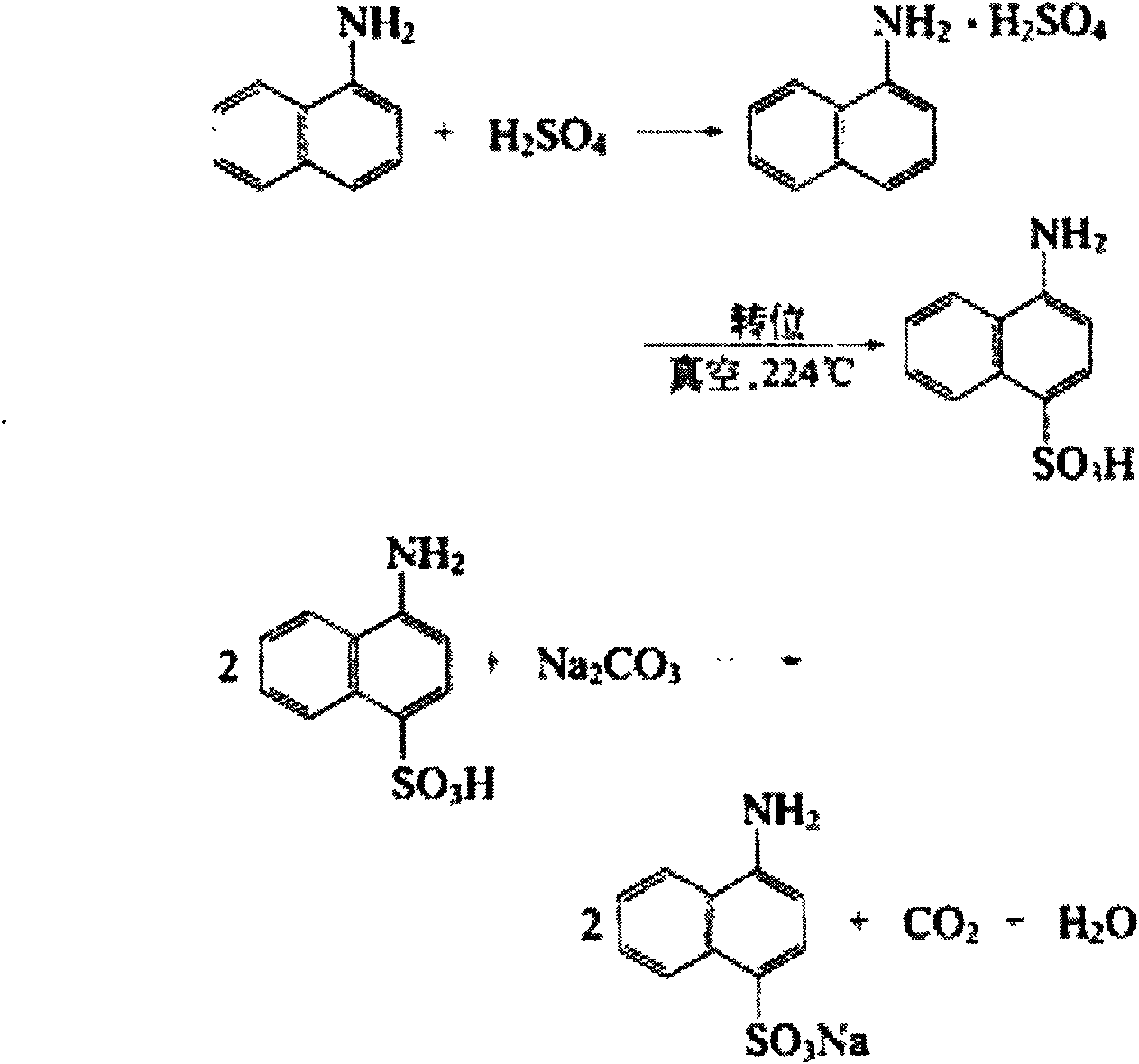

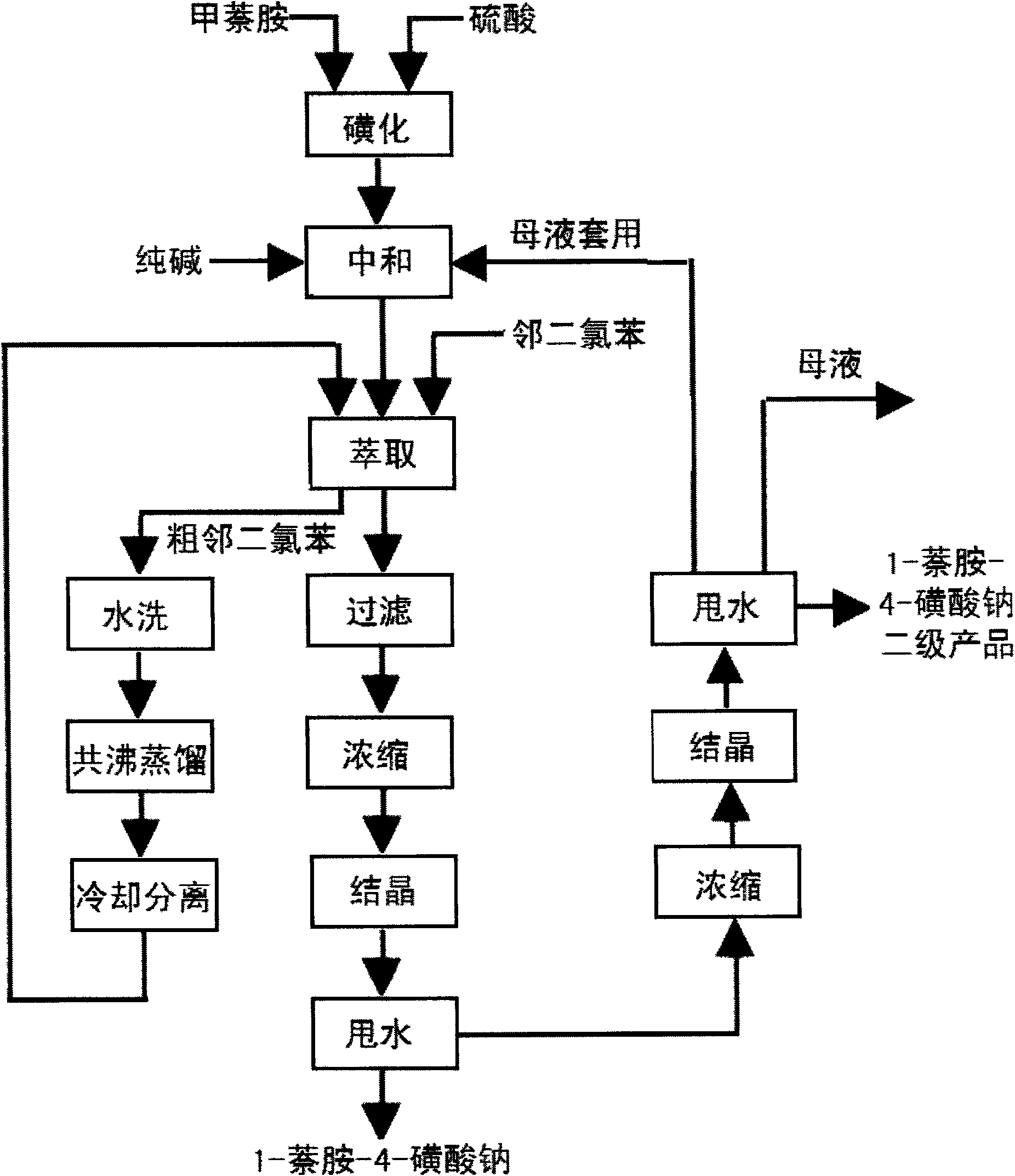

Method used

Image

Examples

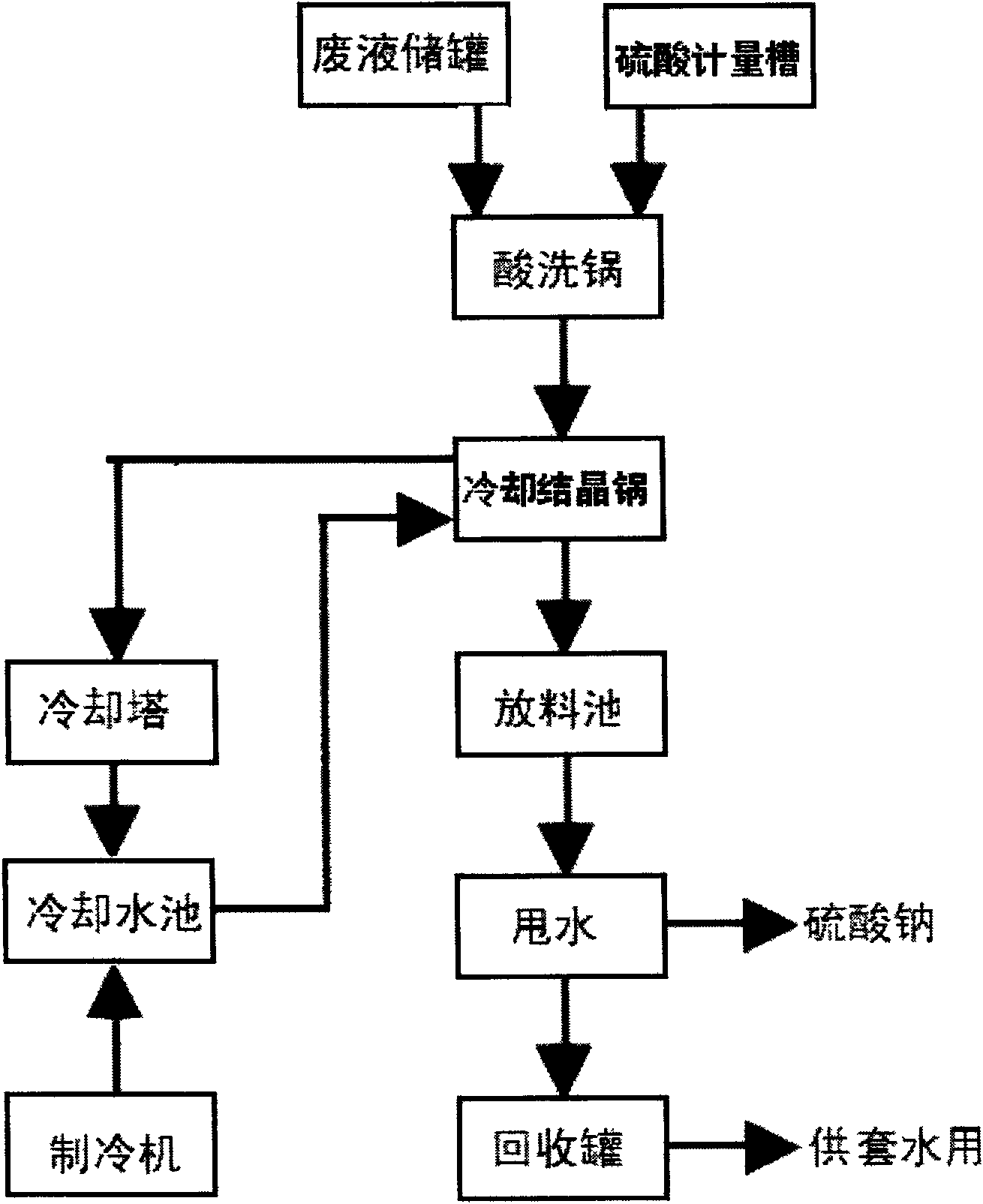

Embodiment 1

[0030] A kettle 1-naphthylamine-4-sodium sulfonate production process waste liquid, which contains 1-naphthylamine-4-sodium sulfonate 10.2%, sodium sulfate 9.9%, sodium carbonate 4.7%, specific gravity is 1.20, and the total weight is 2880kg. Under the condition of 20° C., 127.0 kg of 98% sulfuric acid was added thereto under stirring state, and reacted for 90 minutes to obtain a reaction solution with a pH value of 6.9. Then put the reaction solution into the cooling crystallization pot to cool down to 13°C, and gradually precipitate a large amount of Na 2 SO 4 Crystalline hydrate, the crystallized slurry is placed in a centrifuge to separate Na 2 SO 4 Crystal Hydrate and Crystal Mother Liquor. get Na 2 SO 4 Crystal hydrate 470kg. Na can be washed with water if necessary 2 SO 4 Crystalline hydrate 1-3 times, and continue to dry. 11.7% of sodium 1-naphthylamine-4-sulfonate and 8.6% of sodium sulfate in the crystallization mother liquor have a specific gravity of 1.17...

Embodiment 2

[0032] A kettle 1-naphthylamine-4-sodium sulfonate production process waste liquid, which contains 1-naphthylamine-4-sodium sulfonate 9.9%, sodium sulfate 9.8%, sodium carbonate 5.1%, specific gravity is 1.19, and the total weight is 2720kg. Under the condition of 40° C., 126 kg of 98% sulfuric acid was added thereto under stirring state, and reacted for 90 minutes to obtain a reaction solution with a pH value of 7.05. Then put the reaction solution into the cooling crystallization pot to cool down to 10°C, and gradually precipitate a large amount of Na 2 SO 4 The crystal hydrate is crystallized, and the crystallized slurry is put into a centrifuge to separate the Na 2 SO 4 Crystal hydrate crystallization and crystallization mother liquor. get Na 2 SO 4 530kg of crystal hydrate crystals. Na can be washed with water if necessary 2 SO 4 The crystalline hydrate crystallized 1-3 times, and continued to spin dry. 11.7% of sodium 1-naphthylamine-4-sulfonate and 6.8% of sod...

Embodiment 3

[0034] A kettle 1-naphthylamine-4-sodium sulfonate production process waste liquid contains 10.8% of 1-naphthylamine-4-sodium sulfonate, 9.9% of sodium sulfate, 4.8% of sodium carbonate, a specific gravity of 1.18, and a total weight of 2780kg. Under the condition of 20° C., 125.8 kg of 98% sulfuric acid was added thereto under stirring state, and reacted for 80 minutes. The final temperature was 50° C. to obtain a reaction solution with a pH value of 7.4. Put the reaction solution into the cooling crystallization pot to cool down to 0°C, and gradually precipitate a large amount of Na 2 SO 4 Crystalline hydrate, the crystallized slurry is placed in a centrifuge to separate Na 2 SO 4 Crystal Hydrate and Crystal Mother Liquor. get Na 2 693kg of SO crystal hydrate. The crystallization mother liquor contains 13.7% of sodium 1-naphthylamine-4-sulfonate, 3.8% of sodium sulfate, and a specific gravity of 1.168. The crystallization mother liquor continues to be used as the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com