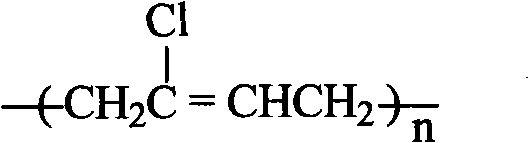

Ternary composite antiaging agent, manufacturing method of emulsion and application in chloroprene rubber

A technology of ternary compounding and manufacturing method, which is applied to the manufacture of ternary compound antioxidants, emulsions and application fields in neoprene rubber, can solve the problems of poor anti-aging performance and environmental pollution, and achieves good thermal stability. , The effect of high antioxidant efficiency and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

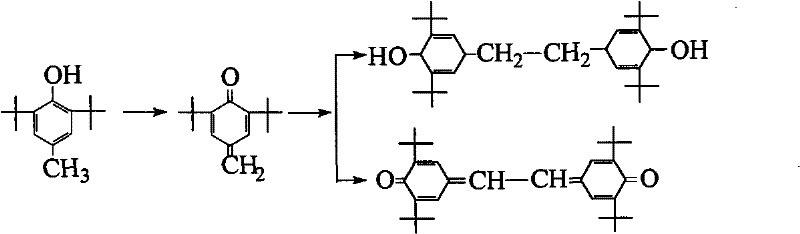

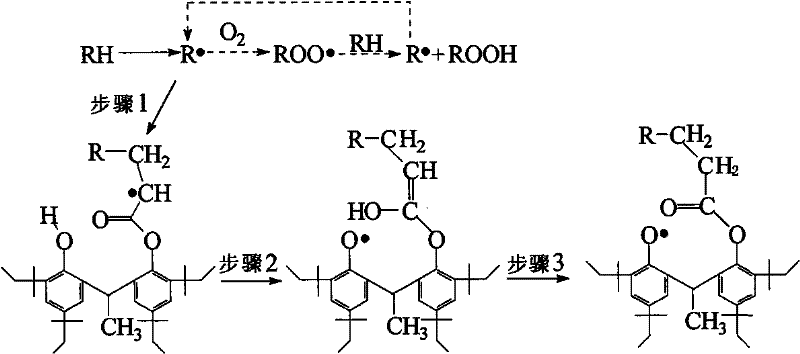

Method used

Image

Examples

Embodiment 1

[0071] Weigh 3000 grams of CR244 neoprene emulsion and 46 grams of 1# ternary composite anti-aging agent emulsion, stir well and mix evenly. After coagulation, washing and drying, a neoprene product with stable properties was obtained, that is, the 1# sample.

Embodiment 2

[0073] Weigh 3000 grams of CR244 neoprene emulsion and 26 grams of 2# ternary composite anti-aging agent emulsion, stir well and mix evenly. After coagulation, washing, and drying, a neoprene product with stable performance was obtained, that is, the 2# sample.

Embodiment 3

[0075] Weigh 3000 grams of CR244 neoprene emulsion and 76 grams of 3# ternary composite anti-aging agent emulsion, stir well and mix evenly. After coagulation, washing, and drying, a neoprene product with stable performance was obtained, that is, the 3# sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com