Preparation method of polymer solvent iso-butane

A technology of isobutane and solvent, which is applied in the field of polymerizing solvent-grade isobutane, can solve the problems of low purity of isobutane, high olefin content, and no improvement, etc., and achieve the effect of improving economic benefits and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

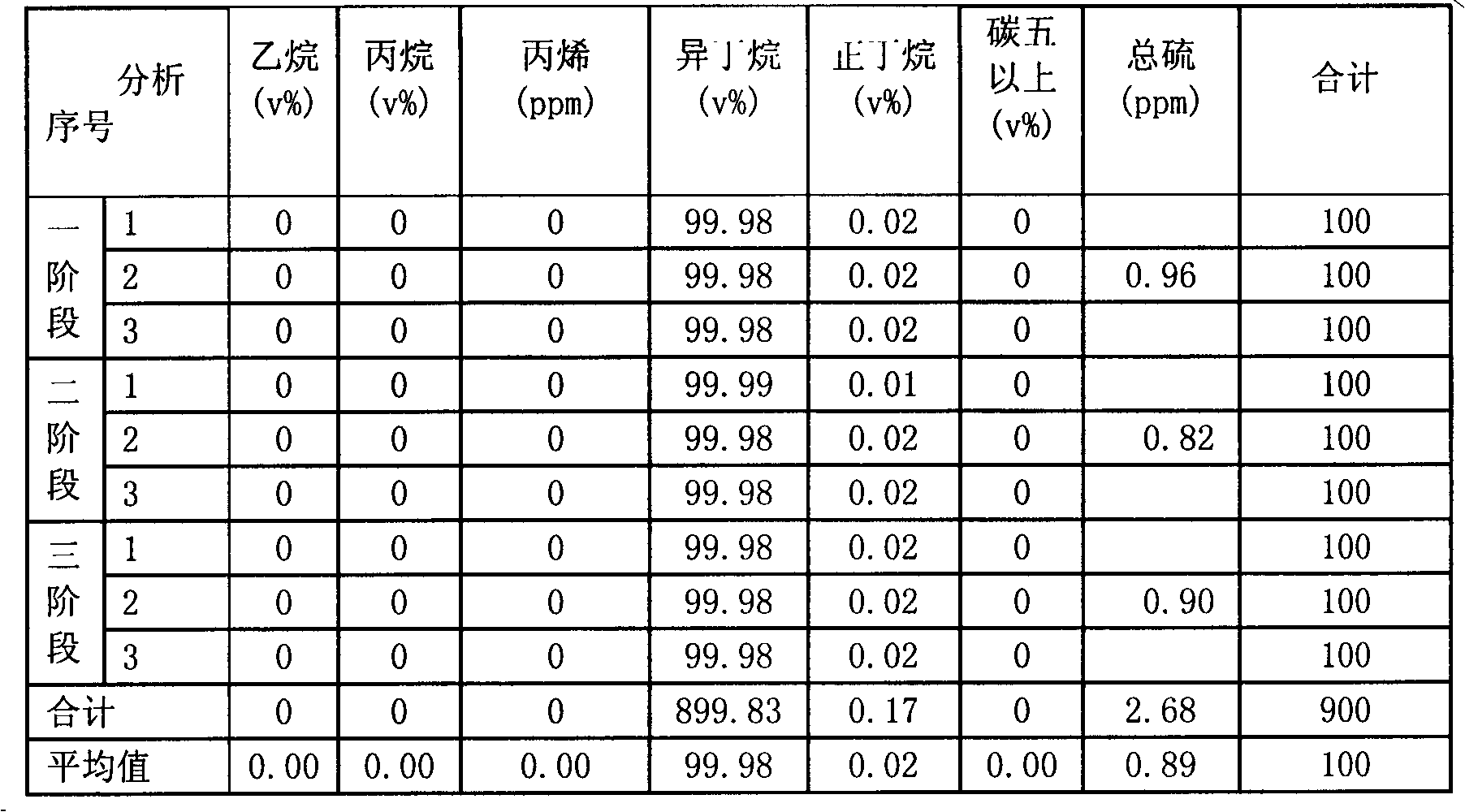

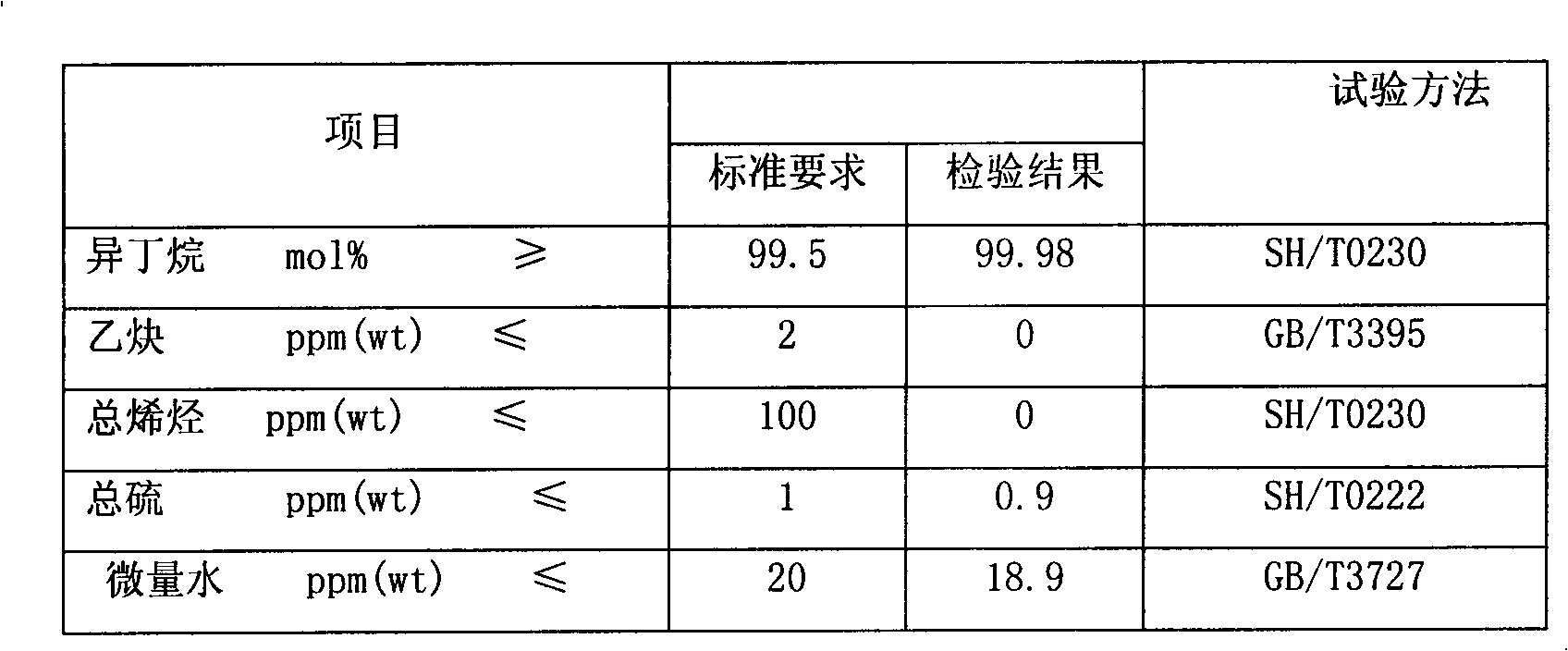

Examples

Embodiment 1

[0024] Hydrocracking liquefied petroleum gas raw material composition (v%): ethane 1.13%, propane 14.2%, isobutane 47.44%, n-butane 33.36%, total butene (ppm) 71.0, carbon five or more 3.87%, total sulfur (ppm) 5.27~6.32.

[0025] Its preparation steps are:

[0026] (1) Mix hydrocracked liquefied petroleum gas and hydrogen at a volume ratio of 1:80, and then preheat to 280°C;

[0027] (2) send into hydrogenation reactor, there is hydrogenation catalyst in hydrogenation reactor, and loading capacity is 68% of effective volume of hydrogenation reactor, and this hydrogenation catalyst is made up of the raw material of following percentage by weight: molybdenum oxide 11 parts, 3 parts of cobalt oxide, 4 parts of nickel oxide, 80 parts of aluminum oxide, the control conditions of hydroprocessing:

[0028] Reaction temperature: 220°C, reaction pressure: 2.4MPa, reaction space velocity: 1.5h -1 ;

[0029] (3) send into desulfurization reactor, desulfurization agent zinc oxide is ...

Embodiment 2

[0037] Hydrocracking liquefied petroleum gas feedstock composition (v%): ethane 0.91-2.09%, propane 14.33-18.92%, propylene (ppm) 45.6-65.9, isobutane 46.12-48.39%, n-butane 28.95-33.22%, N-isobutene (ppm) 132.1-166.5, trans-butene-2 (ppm) 37.6-58, cis-butene-223.21-33.9%, dimethylpropane (ppm) 0.03-224.3, carbon five or more 3.87-4.42%, total Sulfur (ppm) 5.27-6.32.

[0038] Its preparation steps are:

[0039] (1) Mix hydrocracked liquefied petroleum gas and hydrogen at a volume ratio of 1:100, and then preheat to 220°C;

[0040] (2) send into hydrogenation reactor, there is hydrogenation catalyst in hydrogenation reactor, and loading is 68% of effective volume of hydrogenation reactor, and this hydrogenation catalyst is made up of the raw material of following percentage by weight: 13 parts of molybdenum oxides, 2 parts of cobalt oxide, 6 parts of nickel oxide, 70 parts of aluminum oxide, the control conditions of hydroprocessing:

[0041] Reaction temperature: 220°C, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com