Method for preparing photocatalyst with core-shell structure

A technology of core-shell structure and photocatalyst, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of cumbersome preparation process, high energy consumption, easy falling off, etc., and achieve simple preparation process, The effect of large specific surface area and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

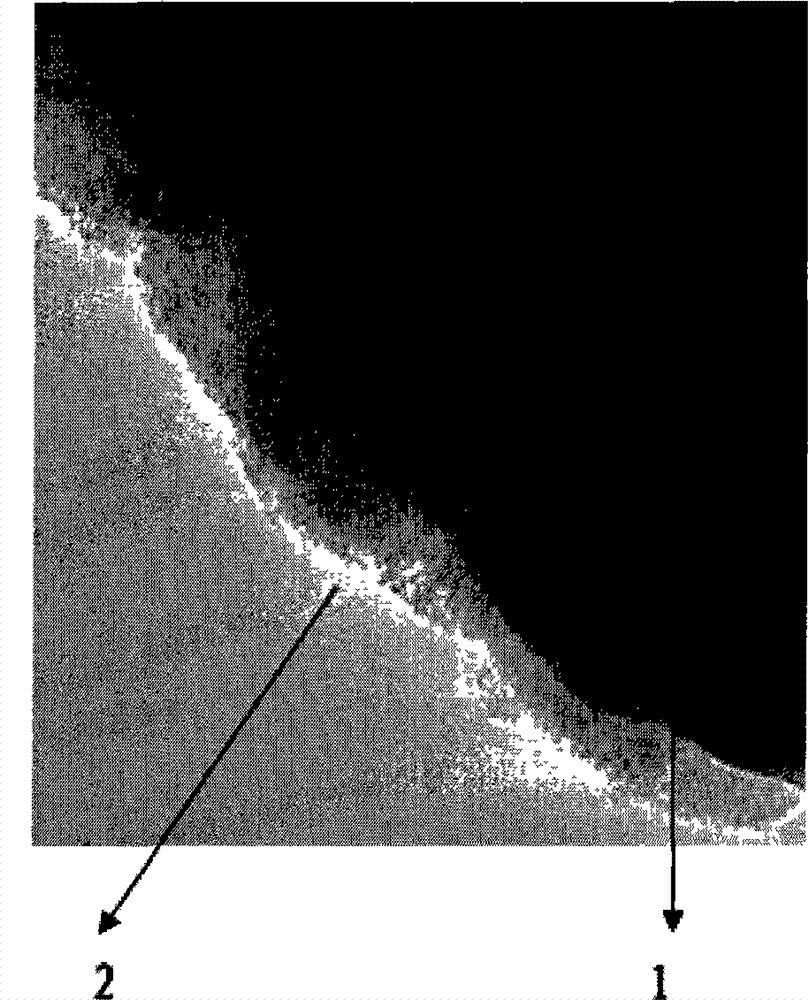

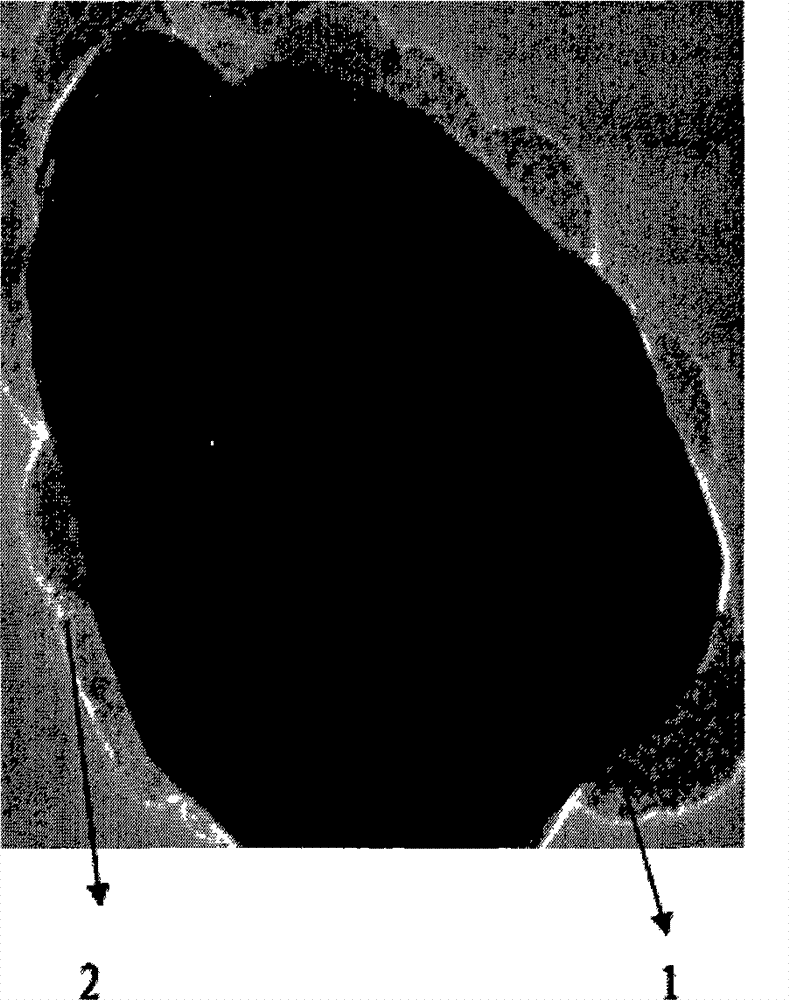

Image

Examples

Embodiment 1

[0038] 1. Activation of acid-resistant non-metallic ores or non-metallic synthetic compounds and removal of acid-soluble impurities:

[0039] 1. Disperse 800 grams of 1250 mesh barium sulfate in 1500 milliliters of 20% hydrochloric acid solution to prepare a suspension,

[0040] 2. Maintain the stirring speed at 150 rpm, temperature at 75°C for 2 hours,

[0041] 3. Cool, filter, and wash with water until there is no Cl - .

[0042] Two, titanium tetrachloride secondary hydrolyzate preparation:

[0043] 1. Dissolve 3 grams of polyethylene glycol 2000 in 150 milliliters of 20% hydrochloric acid solution;

[0044] 2. Add the mixed solution configured in step 1 dropwise to 120 ml of titanium tetrachloride solution to obtain a brown-black hydrolyzate;

[0045] 3. Add 0.4 g of sodium octadecyl sulfate to the hydrolyzate in step 2, maintain the temperature at 85° C., maintain the stirring speed at 300 rpm, and stir and heat for 1 hour.

[0046] 3. Core-shell deposition coating: ...

Embodiment 2

[0051] 1. Activation of acid-resistant non-metallic ores or non-metallic synthetic compounds and removal of acid-soluble impurities:

[0052] 1. Disperse 800 grams of 12500 mesh mica in 2400 milliliters of 10% hydrochloric acid solution to prepare a suspension,

[0053] 2. Maintain the stirring speed at 100 rpm, temperature at 85°C for 4 hours,

[0054] 3. Cool, filter, and wash with water until there is no Cl - .

[0055] Two, titanium tetrachloride secondary hydrolyzate preparation:

[0056] 1. Dissolve 5 grams of sodium polyacrylate and polyethylene glycol 2000 in 240 milliliters of 10% hydrochloric acid solution;

[0057] 2. Add the mixed solution configured in step 1 dropwise to 120 ml of titanium tetrachloride solution to obtain a brown-black hydrolyzate;

[0058] 3. Add 0.5 g of sodium octadecyl sulfate to the hydrolyzate in step 2, maintain the temperature at 90° C., maintain the stirring speed at 300 rpm, and stir and heat for 3 hours.

[0059] 3. Core-shell deposi...

Embodiment 3

[0064] 1. Activation of acid-resistant non-metallic ores or non-metallic synthetic compounds and removal of acid-soluble impurities:

[0065] 1. Disperse 800 grams of 800 mesh kaolin in 5600 milliliters of 25% hydrochloric acid solution to prepare a suspension,

[0066] 2. Maintain the stirring speed at 150 rpm, temperature at 50°C for 0.5 hours,

[0067] 3. Cool, filter, and wash with water until there is no Cl - .

[0068] Two, titanium tetrachloride secondary hydrolyzate preparation:

[0069] 1. Dissolve 7 grams of sodium polyacrylate in 560 milliliters of 25% hydrochloric acid solution;

[0070] 2. Add the mixed solution configured in step 1 dropwise to 120 ml of titanium tetrachloride solution to obtain a brown-black hydrolyzate;

[0071] 3. Add 0.6 g of sodium octadecyl sulfate to the hydrolyzate in step 2, maintain the temperature at 40° C., maintain the stirring speed at 300 rpm, and stir and heat for 0.5 hours.

[0072] 3. Core-shell deposition coating:

[0073]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com