Photosensitive resin composition, photosensitive element, method of forming resist pattern, and process for producing printed wiring board

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve the problems such as disorder of resist image, decrease of resist performance, easy entrainment of air, etc., and achieve the effect of excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0226] Hereinafter, the present invention will be more specifically described based on examples and comparative examples, but the present invention is not limited to the following examples.

Synthetic example 1

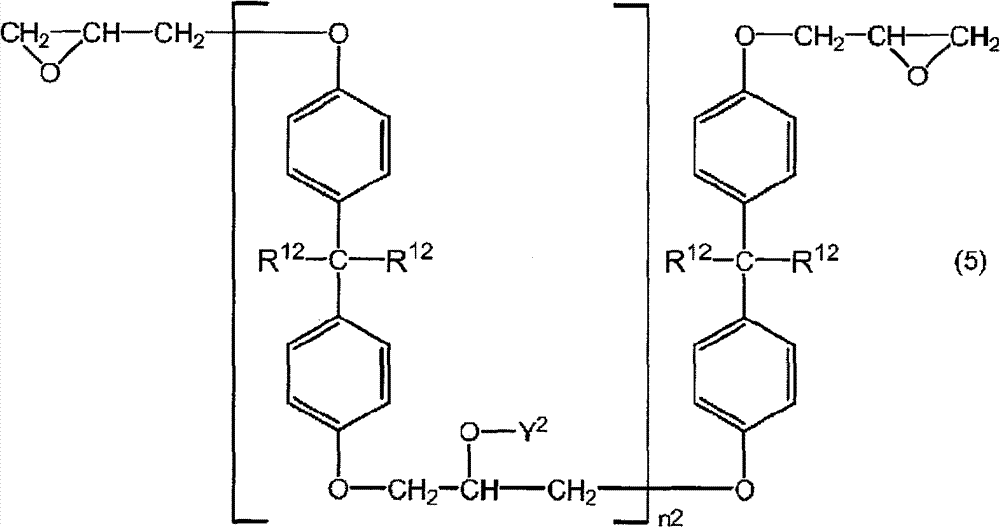

[0228] Add 475 parts by mass of YDF2001 (manufactured by Dongdu Chemical Industry Co., Ltd., bisphenol F type epoxy resin, which is Y in the general formula (5) 2 = glycidyl, R 12 = hydrogen atom), 72 parts by mass of acrylic acid, 0.5 parts by mass of hydroquinone, and 120 parts by mass of carbitol acetate were heated and stirred at 90° C. to dissolve the reaction mixture. Next, the obtained solution was cooled to 60 degreeC, 2 mass parts of benzyltrimethylammonium chlorides were added there, it heated again at 100 degreeC, and it was made to react until the solid content acid value became 1 mgKOH / g. Furthermore, 98 parts by mass of maleic anhydride and 85 parts by mass of carbitol acetate were added, heated to 80° C., and reacted for about 6 hours. Then, it was cooled to room temperature and diluted with carbitol acetate to a solid content concentration of 60% by mass to obtain a carboxylic acid-modified bisphenol F type epoxy acrylate (hereinafter referred to as "epoxy acr...

Synthetic example 2

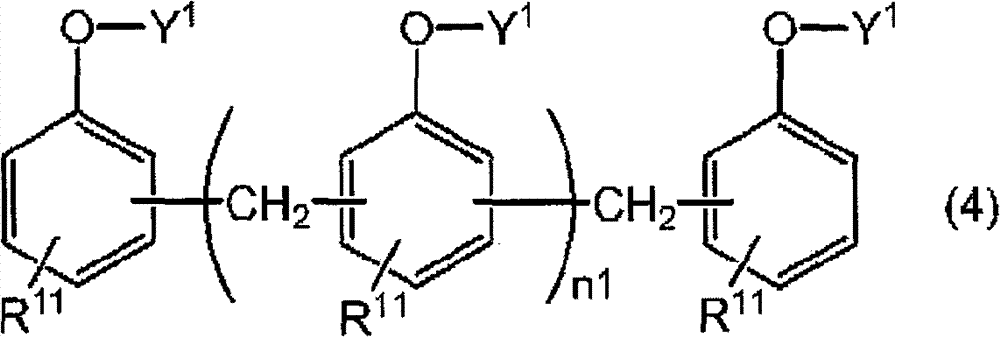

[0230] Add 220 parts by mass of YDCN704 (manufactured by Dongdu Chemical Industry Co., Ltd., cresol novolac type epoxy resin, which is Y in the general formula (4) 1 = glycidyl, R 11 = methyl compound), 72 parts by mass of acrylic acid, 1.0 parts by mass of hydroquinone, and 180 parts by mass of carbitol acetate were heated and stirred at 90° C. to dissolve the reaction mixture. Next, the obtained solution was cooled to 60° C., 1 part by mass of benzyltrimethylammonium chloride was added thereto, and it was heated to 100° C. and reacted until the solid content acid value became 1 mgKOH / g. Furthermore, 152 parts by mass of tetrahydrophthalic anhydride and 100 parts by mass of carbitol acetate were added, heated to 80° C., and reacted for about 6 hours. Then, it was cooled to room temperature, and diluted to a solid content concentration of 60% by mass with carbitol acetate to obtain a carboxylic acid-modified cresol novolak-type epoxy acrylate (hereinafter referred to as "cycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com