Novel process for removing metal ions in wet-process phosphoric acid

A technology of wet-process phosphoric acid and metal ions, applied in the direction of non-metallic elements, phosphorus compounds, chemical instruments and methods, etc., can solve the problems of complicated process, insufficient purification depth, difficult process, etc., and achieve simple process flow and improved exchange capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

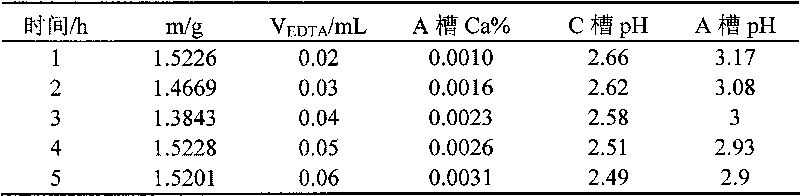

Examples

Embodiment 1

[0027] 50g polyacrylonitrile fiber is cut into the short fiber that length is 3cm, for subsequent use; Accurately weigh 120g sodium hydroxide solid, dissolve with the ethanol solution of 1700mL95% (mass) in beaker, then put the sodium hydroxide that is equipped with Put the ethanol aqueous solution container on the constant temperature water bath, add the short fiber into it, condense and reflux in the constant temperature water bath at 100°C, react for 6 hours, take out the fiber after cooling, and slowly stir the fiber with an appropriate amount of deionized water to make it swell , then use a Buchner funnel to filter it naturally, then rinse the filter cake with deionized water, and repeat this until the pH of the liquid flowing out from the bottom of the Buchner funnel is 8, and when there is no liquid flowing out from the bottom, a wet fiber is obtained; repeat the operation , make about 1000g polyacrylonitrile wet state ion exchange fiber standby.

[0028] Fill 650g poly...

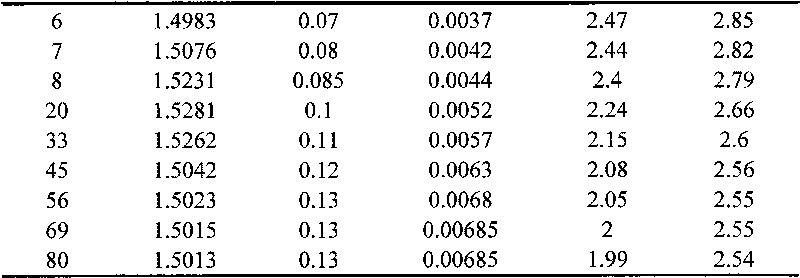

Embodiment 2

[0036] Cut 50g of polyacrylonitrile fibers into short fibers with a length of 3cm for later use; accurately weigh 120g of sodium hydroxide solid, dissolve it in a beaker with 1700mL of 95% ethanol solution, and then put the configured sodium hydroxide ethanol solution container Put it on a constant temperature water bath, add short fibers into it, condense and reflux in a constant temperature water bath at 120°C, react for 5 hours, take out the fiber after cooling, slowly stir the fiber with an appropriate amount of deionized water to make it swell, and then use The Buchner funnel is allowed to filter naturally, and then the filter cake is washed with deionized water, and so on, until the pH of the liquid flowing out from the bottom of the Buchner funnel is 8, and the wet fiber is obtained when no liquid flows out from the bottom; repeated operations, obtained About 1000g polyacrylonitrile wet state ion exchange fiber is standby.

[0037] Fill 650g polyacrylonitrile wet ion-ex...

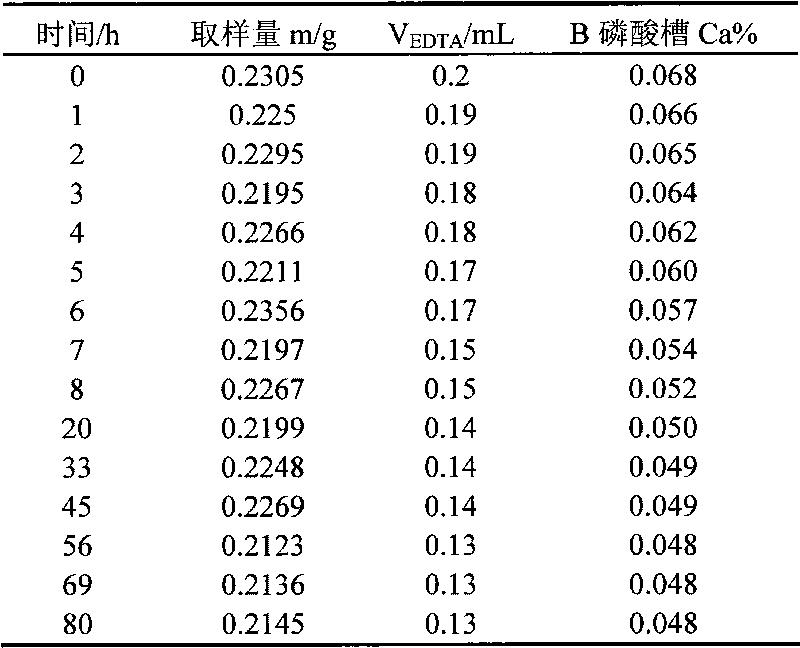

Embodiment 3

[0040] Cut 50g of polyacrylonitrile fibers into short fibers with a length of 0.3cm for later use; accurately weigh 120g of sodium hydroxide solid, dissolve it in a beaker with 1700mL of 95% ethanol solution, and then put the prepared sodium hydroxide ethanol solution Place the container on a constant temperature water bath, add short fibers into it, condense and reflux in a constant temperature water bath at 70°C, react for 8 hours, take out the fiber after cooling, slowly stir the fiber with an appropriate amount of deionized water to make it swell, and then Use a Buchner funnel to filter it naturally, then rinse the filter cake with deionized water, and repeat this until the pH of the liquid flowing out from the bottom of the Buchner funnel is 8, and when no liquid flows out from the bottom, a wet fiber is obtained; repeat the operation to prepare Get about 1000g polyacrylonitrile wet state ion exchange fiber for subsequent use.

[0041] Fill 650g polyacrylonitrile wet ion-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com