Method for preparing Ti -Si molecular sieve membrane by microwave radiating heating

A titanium-silicon molecular sieve and microwave radiation technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of increasing the crystal gap of molecular sieve membranes, the long synthesis time of seed crystal method, and the amplification of molecular sieve membranes, etc., to achieve heating speed Fast, excellent catalytic performance, the effect of shortening the crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

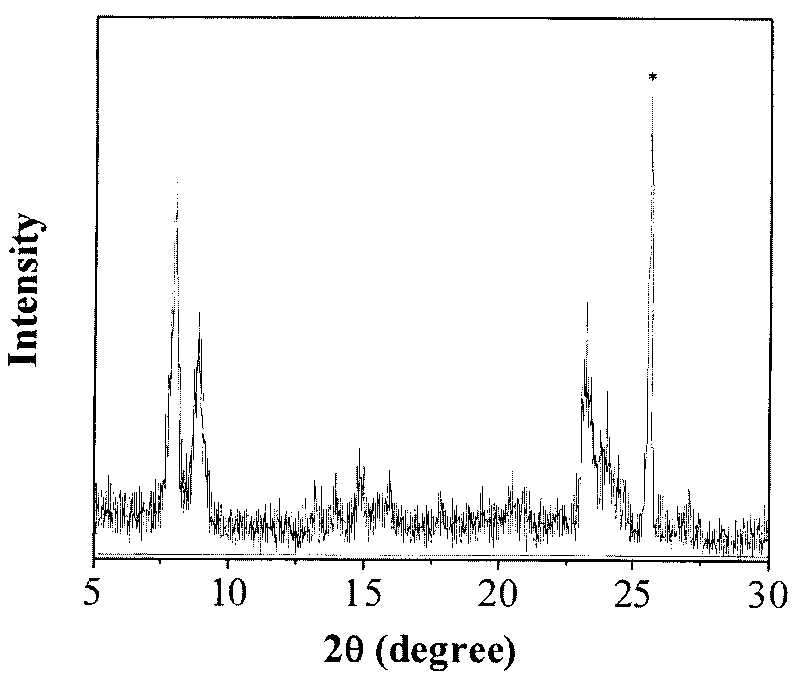

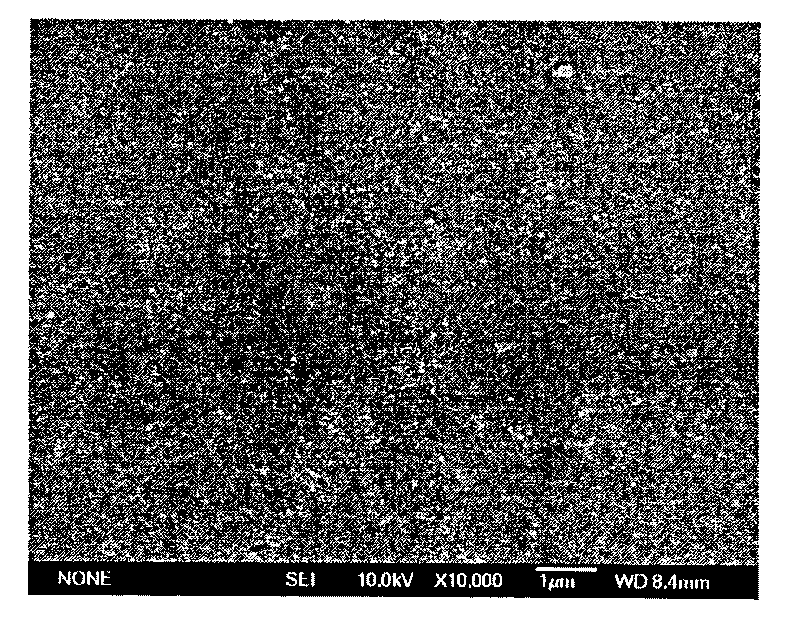

Embodiment approach 1

[0018] Slowly add orthoethyl silicate (TEOS) dropwise into an aqueous solution of tetrapropylammonium hydroxide (8%), stir vigorously at room temperature until the solution is clear, and tetrabutyl titanate (TBOT) is dissolved in isopropanol , slowly add it dropwise to the aforementioned sol at 0°C under the protection of nitrogen, stir for 1 hour, carefully raise the temperature to 80°C, keep the temperature constant for 2 hours, add water to the original liquid level, and obtain a milky white precursor colloid synthesis liquid, its composition TEOS: 0.01TBOT: 0.25TPAOH: 40H 2 O, the precursor colloid synthesis liquid and α-Al 2 o 3 The carrier is placed in the crystallization kettle, α-Al 2 o 3 The upper surface of the carrier is in contact with the synthesis liquid, heated at 180°C, 900MHz microwave radiation field for 3.5 hours, after the crystallization is completed, the reactor is quenched, the sample is taken out, rinsed with deionized water, dried, and calcined at 5...

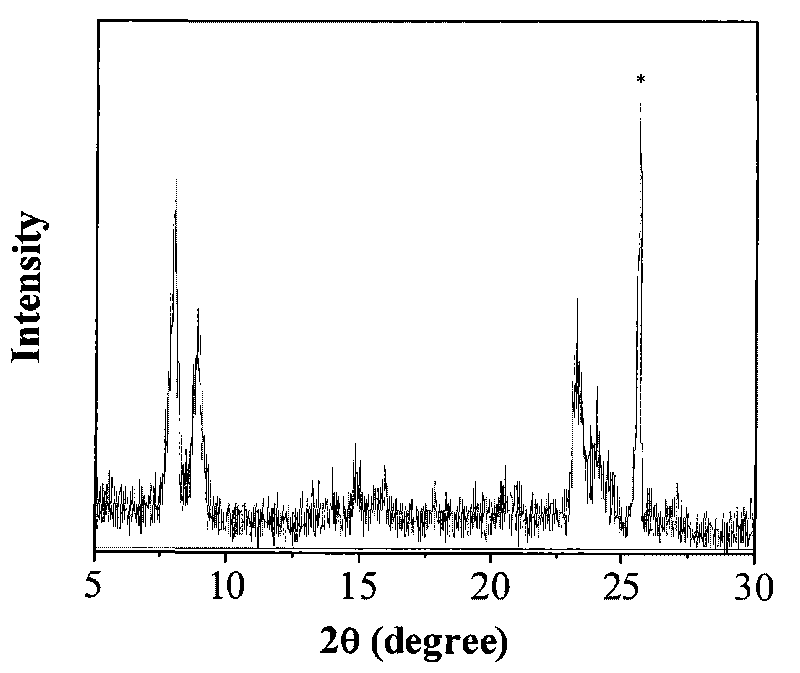

Embodiment approach 2

[0020] The composition of precursor colloid synthesis solution is TEOS: 0.01TBOT: 0.20TPAOH: 46H 2 O, heated at 180° C. for 3.5 hours in a microwave radiation field of 1600 MHz, and the others are the same as Embodiment 1.

Embodiment approach 3

[0022] The composition of precursor colloidal synthesis liquid is: TEOS: 0.015TBOT: 0.16TPAOH: 50H 2 O, heating at 180° C., 4500 MHz microwave radiation field for 3 hours, and sintering at 550° C. for 2 hours. Others are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com