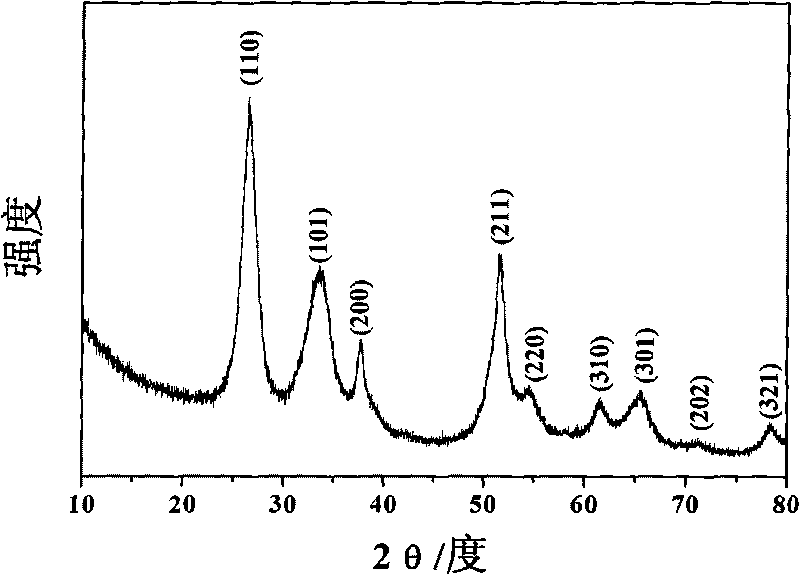

Method for preparing tin dioxide nanostructure material with floriform appearance by hydrothermal synthesis

A technology of tin dioxide and hydrothermal synthesis, applied in nanostructure manufacturing, tin oxide, nanotechnology, etc., can solve problems such as high reaction temperature, complicated reaction conditions, and long reaction time, and achieve high product purity and simple raw materials , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

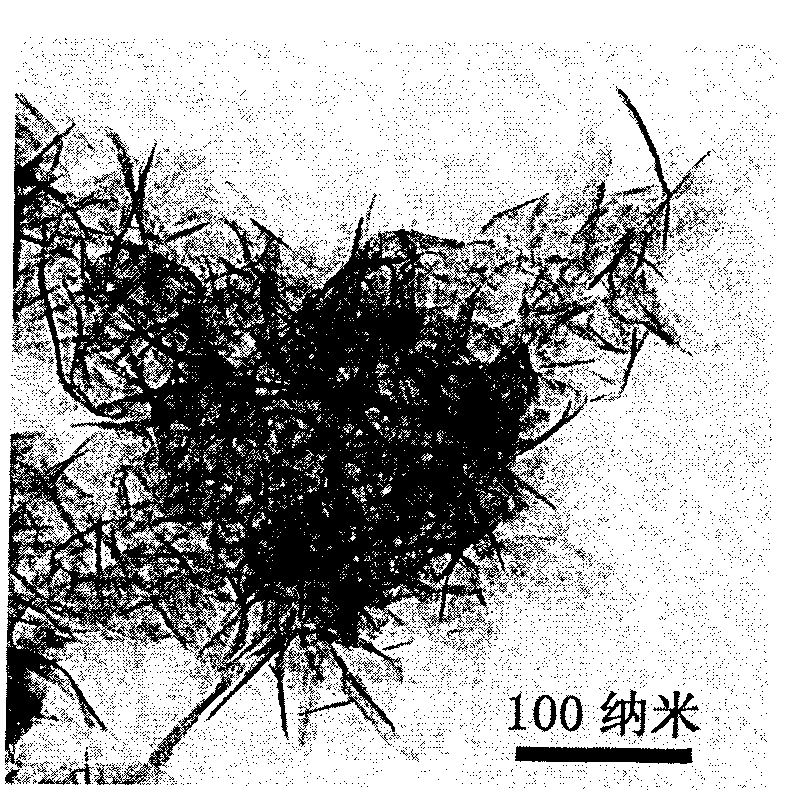

[0027] Follow the preparation process. Add 0.374g tin dichloride dihydrate into a beaker filled with 49ml ethanol and 49ml deionized water mixed solvent, and magnetically stir for 5 minutes to obtain a translucent white turbid solution; add 7ml ammonia solution (mass concentration 25%-28% ), and continued to stir for 60 minutes; this time, it was a milky white suspension, which was the precursor of tin dioxide. Put the liner of the polytetrafluoroethylene reactor containing the reaction solution into a stress-free stainless steel reactor, and place it in an intelligent temperature-controllable muffle furnace for continuous heating. The reaction conditions are: 120°C, 6h. After the reaction, the solution was centrifuged at a centrifugal rate of 10000r / min for 15min. After repeated centrifugation for 5 times, the solid obtained was vacuum-dried at room temperature into a powder. The transmission electron microscope test sample is to take out a small amount of the solid powder ...

Embodiment 2

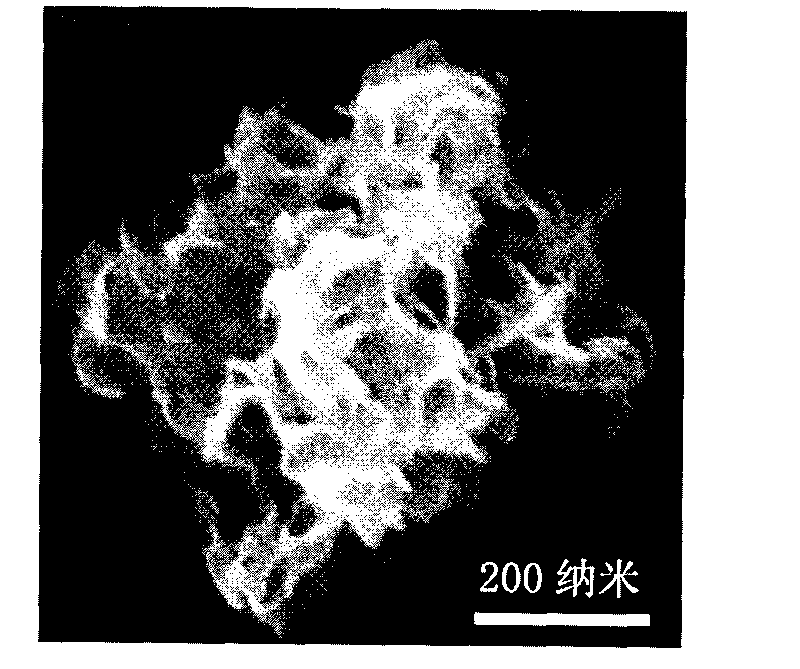

[0029] Follow the preparation process. 0.374g tin dichloride dihydrate is added in the beaker that fills the ethanol of 4.9ml and the mixed solvent of 93.1ml deionized water, and magnetically stirred for 5 minutes to obtain a translucent white turbid solution; -28%), and continued to stir for 60 minutes; this time, it was a milky white suspension, which was the precursor of tin dioxide. The polytetrafluoroethylene reactor liner filled with the reaction solution is put into a stress-free stainless steel reactor, and placed in an intelligent temperature-controllable muffle furnace for continuous heating. The reaction conditions are: 120°C, 6h. After the reaction, the solution was centrifuged at a centrifugal rate of 10000r / min for 15min. The solid obtained after centrifugation for 5 times was vacuum-dried at room temperature into a powder. The product is a mixture of flakes of tin dioxide flower-like clusters and nanoparticles.

Embodiment 3

[0031] Follow the preparation process. Add 0.374g tin dichloride dihydrate into a beaker containing 24.5ml ethanol and 73.5ml deionized water mixed solvent, and magnetically stir for 5 minutes to obtain a translucent white turbid solution; add 7ml ammonia solution (mass concentration 25%- 28%), and continued to stir for 60 minutes; this time, it was a milky white suspension, which was the precursor of tin dioxide. The polytetrafluoroethylene reactor liner filled with the reaction solution is put into a stress-free stainless steel reactor, and placed in an intelligent temperature-controllable muffle furnace for continuous heating. The reaction conditions are: 120°C, 6h. After the reaction, the solution was centrifuged at a centrifugal rate of 10000r / min for 15min. The solid obtained after centrifugation for 5 times was vacuum-dried at room temperature into a powder. The product is a mixture of tin dioxide flower clusters and nanoparticles. The transmission electron microscop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com