Improved method of excess calcium hydrate detoxification during cellulose ethanol production

A technology of cellulosic ethanol and calcium hydroxide, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of large amount of calcium hydroxide and low conversion rate of cellulosic ethanol, and achieve low price, Simple equipment, good fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

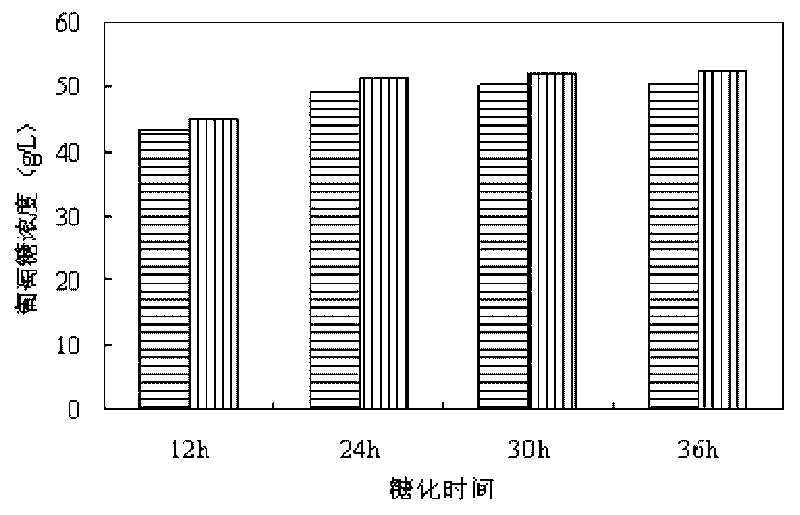

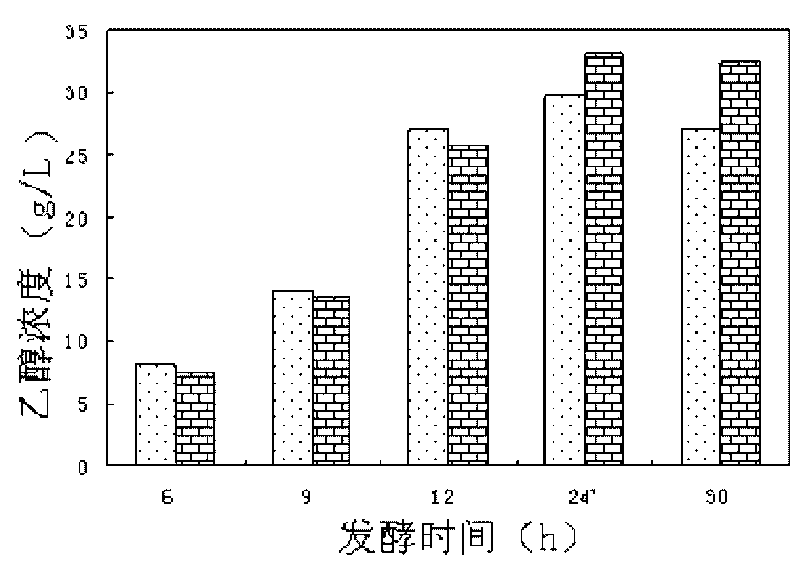

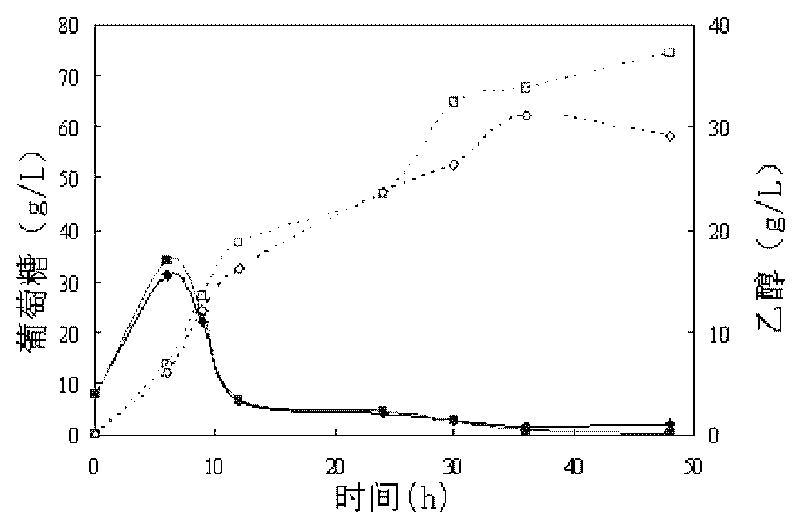

[0011] Specific Embodiment 1: In this embodiment, the method for improving the detoxification of excessive calcium hydroxide in the production of cellulose ethanol is carried out according to the following steps: 1. Cut the mature corn stalks into sections, and then heat the corn stalks at a temperature of 220-240°C and a pressure of 1.6-1.8 Steam explosion pretreatment under the condition of MPa for 4-6 minutes to obtain steam-exploded straw; 2. Put the steam-exploded straw into distilled water and mix, then stir for 20-30 minutes at a stirring speed of 150-300r / min, filter, Obtain filtrate A and filter residue; 3. Use calcium hydroxide to adjust the pH of filtrate A to 10-11, then heat-preserve it in a water bath at 65°C for 20-30 minutes, then cool to room temperature and filter to obtain filtrate B; 4. Put the filtrate B into the filter residue in step 1 and adjust the pH to 4.8-5.5, then sterilize with moist heat for 20 minutes at a temperature of 121°C, then add cellulase...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment is different from Embodiment 1 in that the mature corn stalks in step 1 are cut into 4-6 cm segments. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment is different from Embodiment 1 in that the mature corn stalks in step 1 are cut into 5 cm segments. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com