Method for preparing nano manganese dioxide of different crystal forms and appearances by adopting microwave hydrothermal method

A technology of nano-manganese dioxide and microwave hydrothermal method, which is applied in the direction of manganese oxide/manganese hydroxide, nanotechnology, nanotechnology, etc., can solve the problem that the crystal form and shape of the reaction product are difficult to control, and achieve controllable product quality , wide applicability, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

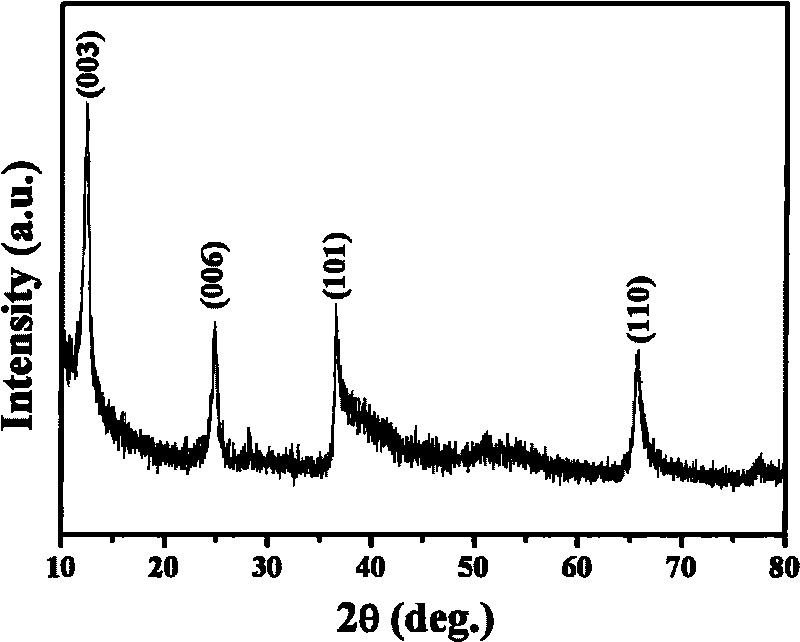

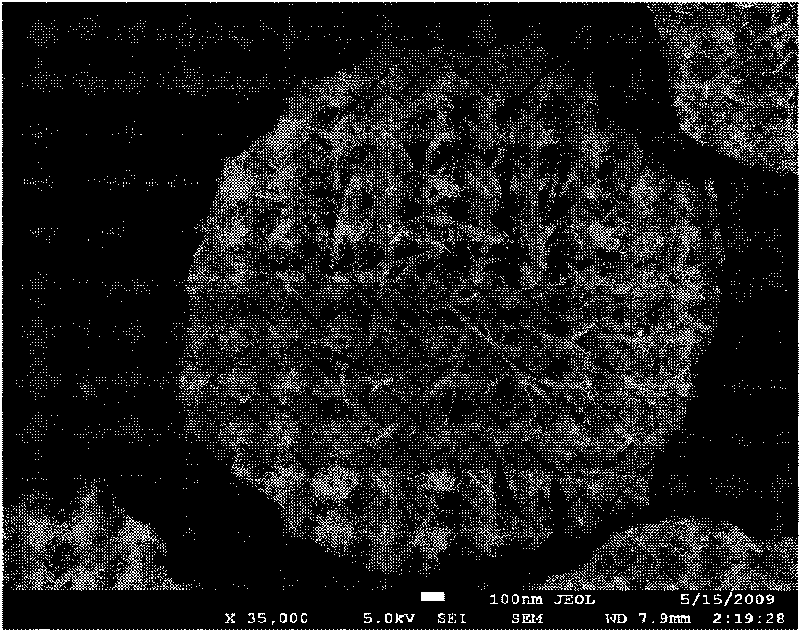

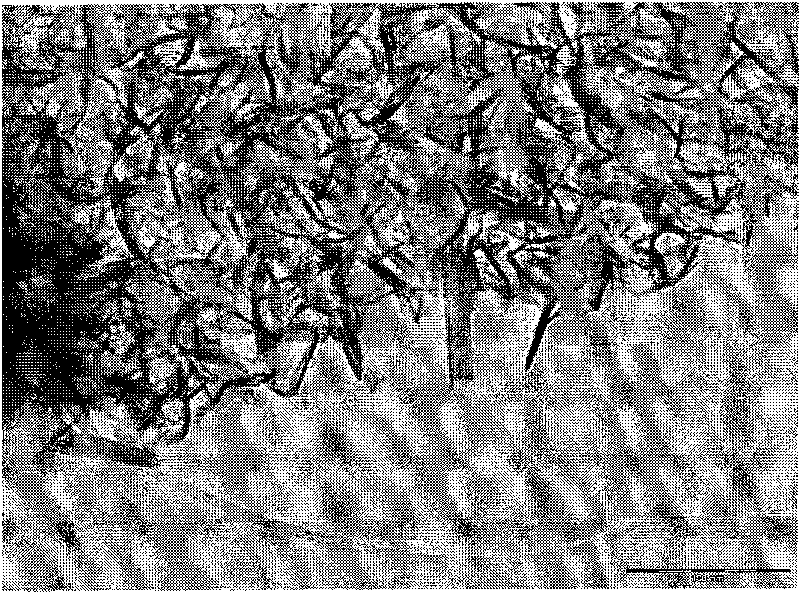

[0025] First weigh 2.53g of analytically pure potassium permanganate KMnO 4 Dissolve in 300ml of deionized water, then add 5-6ml of concentrated hydrochloric acid with a mass concentration of 36% to the solution, add water to make the total amount of the solution reach 400ml, stir until the solution is uniform, pour the prepared solution into The sealable reaction vessel is placed in a microwave field (microwave frequency is 2.45GHz) for microwave irradiation, the solution temperature is controlled at 110°C, and the holding time is 1 hour. After the reaction, the generated precursors are separated, washed and dried. Figure 1 ~ Figure 3 The picture obtained for characterizing the product obtained in Example 1, wherein, figure 1 It is the XRD pattern of the product, which is very consistent with the spectral line No.52-0556 of δ-phase manganese dioxide with rhombohedral structure in the JCPDS database, indicating that the product is δ-phase manganese dioxide; the electron micro...

Embodiment 2

[0027] First weigh 2.53g of analytically pure potassium permanganate KMnO 4 Dissolve in 300ml of deionized water, then add 5-6ml of concentrated hydrochloric acid with a mass concentration of 36% into the solution, add water to make the total solution to 400ml, stir until the solution is uniform, pour the prepared solution into The sealable reaction vessel was placed in a microwave field (microwave frequency 2.45 GHz) for microwave irradiation, the solution temperature was controlled at 140° C., and the holding time was 1 hour. After the reaction, the generated precursor was separated, washed and dried. Figure 4 ~ Figure 6 The picture obtained for characterizing the product obtained in Example 1, wherein, Figure 4 It is the XRD spectrum of the product, and this spectral line is very consistent with the spectral line No.72-1982 of α-phase manganese dioxide with tetragonal structure in the JCPDS database, indicating that the product is α-phase manganese dioxide; the electron m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com