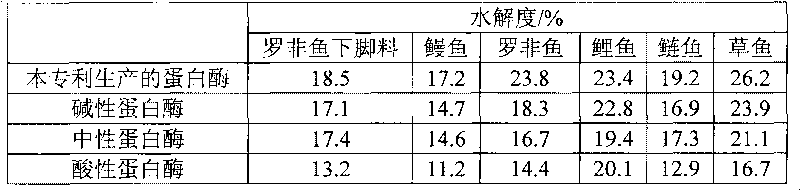

Production method of protease hydrolyzing leftovers of freshwater fish and other fish efficiently

A production method, protease technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problems of expensive products, achieve the effects of improving permeability, strong elastase activity, and promoting secretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0017] The invention is a protease production method capable of efficiently hydrolyzing freshwater fish and fish leftovers. The process steps include: (1) strain activation: the culture medium for strain activation consists of: 0.4% beef extract, 0.6% peptone, Yeast extract 0.2%, NaCl 0.5%, agar 2%, moisture 96.3%, pH 7.5; the culture temperature for strain activation is 37°C, and the culture time is 24h; (2) Seed preparation: the medium composition for seed preparation is: 0.4% beef extract, 0.6% peptone, 0.2% yeast extract, 0.5% NaCl, 98.3% water, pH7.5; the preparation of shake flask strains is carried out in a 250ml Erlenmeyer flask, the amount of seed medium is 20ml, and the seed After the medium is prepared, inoculate the newly activated slant lawn into the medium, put it in a shaker, and cultivate it at 180r / m and 32°C for 24h; the preparation of workshop seeds is carried out in the seed tank. The filling coefficient of the culture medium is 0.7, the inoculum size is 1%...

Embodiment approach 2

[0019] The present embodiment is basically the same as the first embodiment, and the difference is: (3) prepare the Bacillus subtilis culture medium, the composition of the culture medium is: glucose 8%, corn steep liquor powder 1%, K 2 HPO 3 0.2%, MgSO 4 ·7H 2 O0.034%, moisture 90.77%; the filling coefficient of the medium is 0.7; after the medium is sterilized and cooled, the inoculation amount of 10% is inserted into the strain, and the fermentation temperature is 37°C, and the dissolved oxygen is 30% ± 5%. , pH 7.4±0.2 and cultured for 16 hours (4) Add 0.1% inducer and 0.06% triton-100, raise the fermentation temperature to 40°C and keep the dissolved oxygen and pH unchanged, and continue to ferment for 16 hours according to the process specification Step (5) extracting elastase and preparing enzyme powder.

Embodiment approach 3

[0021] The present embodiment is basically the same as the first embodiment, the difference is: (3) prepare the Bacillus subtilis medium, the composition of the medium is: glucose 4.5%, corn steep liquor 0.6%, K 2 HPO 3 0.13%, MgSO 4 ·7H 2 O 0.034%, moisture 94.74%; the filling coefficient of the medium is 0.7; when the medium is sterilized and cooled, insert the newly cultivated seeds with an inoculum of 10%, and ferment at a temperature of 37°C and dissolved oxygen of 30%± After culturing for 14 hours under the conditions of 5%, pH 7.4±0.2, add 0.1% inducer and 0.06% triton-100, increase the fermentation temperature to 37°C and keep the dissolved oxygen and pH unchanged, and continue to ferment for 16 hours according to the process Step (5) of the instruction manual extracts elastase and prepares enzyme powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com