Process and device for treating phenol-containing sewage of producer gas station

A technology for producing furnace gas and treatment process, which is applied in the direction of heating water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems that cannot be adopted, and reduce the cooling load and improve the working environment. Effect of improving and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

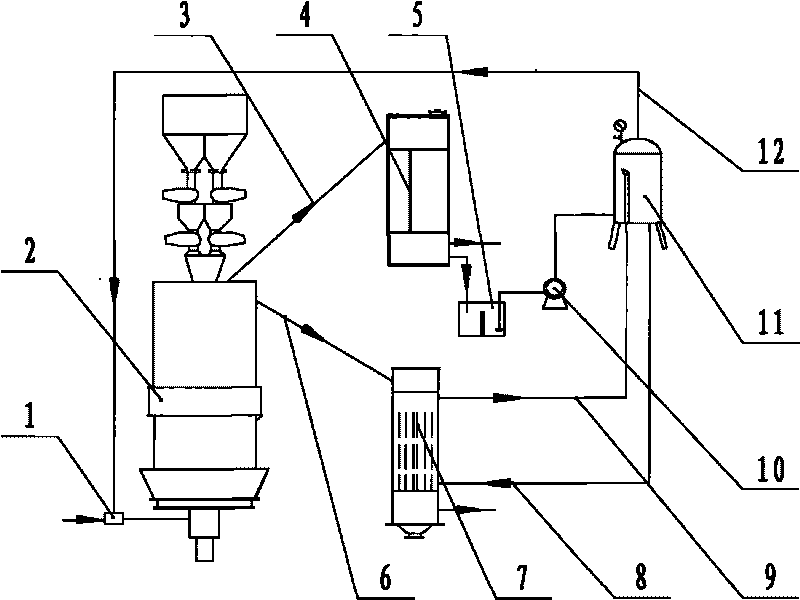

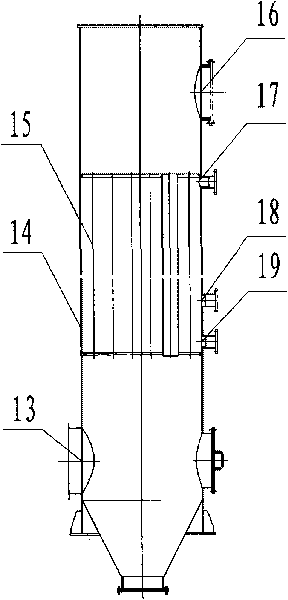

[0032] The phenolic sewage treatment device of the producer gas station, the structure can refer to figure 1 , 2 As shown, it includes a two-stage gasifier 2, an indirect cooler 4, a phenol water evaporator 7 and a phenol water vapor separator 11, and the gas outlet of the upper stage of the two-stage gasifier 2 passes through a pipeline and an indirect cooler 4 Connected with the phenol water vapor separator 11, the phenol water evaporator 7 is divided into a tube side and a shell side, the tube side is provided with a gas inlet 16 and a gas outlet 13, and the shell side is provided with a phenol-containing sewage inlet 18 and a phenol water vapor outlet 17. The phenol-containing sewage inlet 18 and the phenol water vapor outlet 17 are connected to the phenol water vapor separator 11 through pipelines, and the gas outlet of the lower stage of the two-stage gasifier 2 is connected to the shell side of the phenol water evaporator 7 through pipelines. Gas inlet 16 links to each...

Embodiment 2

[0037] The structure of the phenolic sewage treatment device of the producer gas station can still be referred to figure 1 , 2 As shown, but different from Example 1: the 8-ML3.4 two-stage gas generator gas station adopts a phenol water evaporator with an inner diameter of 1400mm, and the heat exchange tube diameter is 159mm, and the length is 4 meters, a total of 37 technical solutions. In addition, a phenol water pool 5 is also provided between the indirect cooler 4 and the phenol water vapor separator 11 . Its purpose is that the phenol-containing sewage formed after being condensed by the indirect cooler 4 needs to be purified in the phenol water tank 5 (such as precipitation, degreasing, filtering, etc.) before entering the phenol water vapor separator 11 for treatment.

[0038] The above-mentioned device is used to treat the phenol-containing sewage of the producer gas station. The mixture of the phenol-containing water vapor generated by heating the bituminous coal in t...

Embodiment 3

[0041] The structure of the phenolic sewage treatment device of the producer gas station can still be referred to figure 1 , 2 As shown, but different from Example 2: the phenol water vapor separator 11 is also connected with the two-stage gasifier 2 through the steam mixer 1, and the phenol water from the phenol water vapor separator 11 After the steam is mixed in the steam mixer 1, it enters the hearth of the two-stage gas generator 2 for reuse. In addition, the 1-ML3.6 two-stage gas generator gas station uses a phenol water evaporator with an inner diameter of 1600mm. The evaporator uses a heat exchange tube with a diameter of 159mm and a length of 5 meters. , a total of 37 heat exchange tubes. Practice has proved that it also has good treatment capacity for phenolic sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com