Driving micro pump of photoinduced bending film

A light-induced bending and driving technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of slow heat dissipation, limited performance, low operating frequency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This embodiment is a micropump with a valve structure.

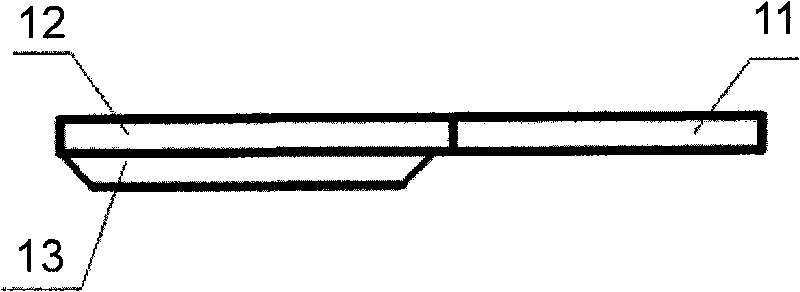

[0017] please see figure 1 As shown, the pump membrane 3 is composed of two layers, the upper layer 1 is made of photobending material, the lower layer 2 is made of flexible polymer material, and the upper layer and the lower layer are bonded by an adhesive. Because if the photobending material is fixed around, its photobending ability will be lost. Therefore, the area of the upper layer of the pump membrane is designed to be smaller than that of the lower layer. It is a local composite, and the boundary of the lower layer is fixed. Irradiating the upper layer of photobending material will cause The deformation of the upper layer material, and then drives the deformation of the lower layer material.

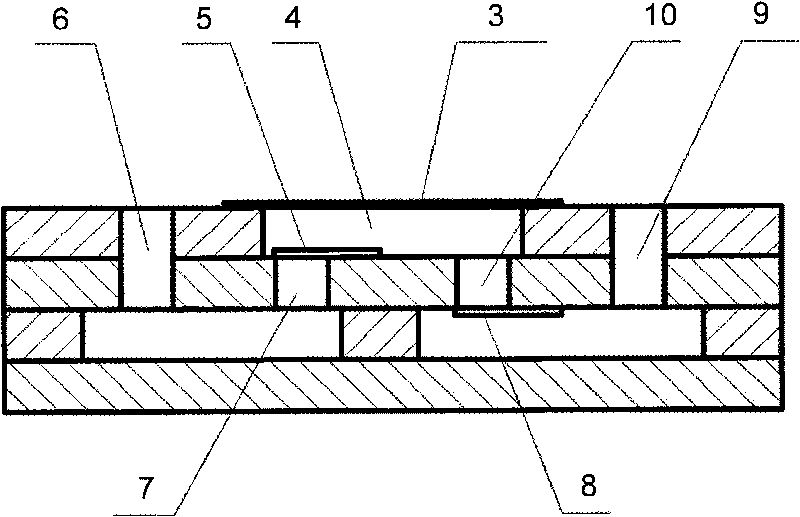

[0018] please see figure 2 As shown, the pump membrane is located at the top of the pump chamber 4, and the deformation of the pump membrane 3 leads to changes in the volume and pressure of the pump chamber. Wh...

Embodiment 2

[0021] This embodiment is a micropump adopting a valveless structure.

[0022] When the ultraviolet light is irradiated, the driving membrane is displaced upward, so that the volume of the pump cavity 4 increases and the pressure decreases. The flow into the pump chamber from the diffusion input port (water inlet 7) is greater than the flow rate from the shrink tube output port (water outlet 10) into the pump chamber, thus generating a net water intake, and the liquid is pumped into the pump chamber; when visible light is irradiated, the membrane is driven When the downward displacement resets, the volume of the corresponding pump chamber 4 decreases and the pressure increases. The original contraction tube becomes a diffuser tube, and the original diffuser tube becomes a contraction tube, and the flow out from the diffuser tube, i.e., the water outlet 10, is more than that from the contraction tube, i.e., the water inlet 7, thus producing a net water output, and the liquid is...

Embodiment 3

[0024] This embodiment is a micropump adopting a cascaded pump structure.

[0025] In view of the bending characteristics of the pump membrane in the present invention, it can be further made into the form of a cascade pump. please see Figure 5 As shown, the water outlet of the previous stage pump chamber 4 is communicated with the water inlet of the rear stage pump chamber, that is, an intermediate chamber is opened to communicate. When the pump membrane 3 of the forward pump is irradiated with ultraviolet light, and the pump membrane 3 of the backward pump is irradiated with visible light, the water inlet valve 5 of the previous pump is opened, the water outlet valve 8 is closed, and the water inlet valve 5 of the rear pump is closed. When the water outlet valve 8 is opened, the previous pump chamber absorbs water, and the latter pump chamber drains. Conversely, when the forward pump membrane 3 is irradiated with visible light and the rear pump membrane 3 is irradiated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com