Metal flange coated with insulating ceramic coating and preparation method thereof

A ceramic insulation and coating technology, applied in the direction of flange connections, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of reduced insulation reliability, easy failure, poor temperature resistance of organic insulation parts, etc., to prevent electric shocks Chemical corrosion, broad application prospects, high temperature resistance and electrical insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

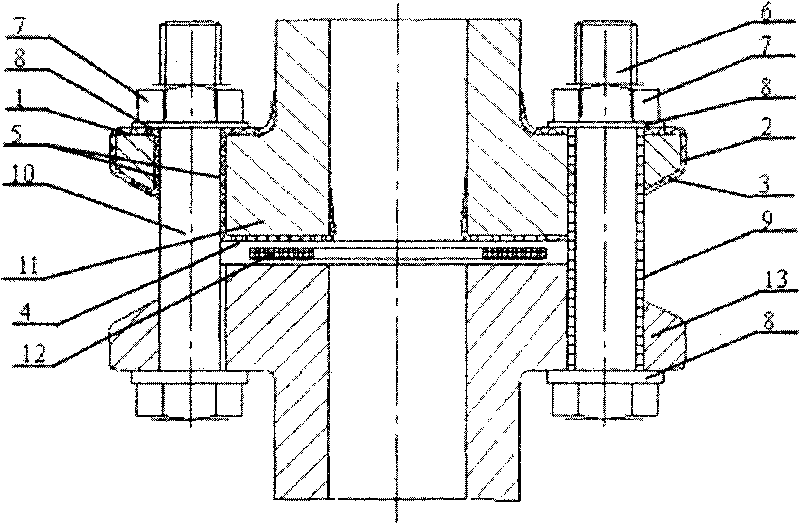

[0040] Take the ceramic insulating coating of the convex flange of the copper pipe section as an example.

[0041] 1) Coating composition: select 0wt% TiO 2 +100wt%Al 2 o 3 .

[0042] 2) Coating position: other appearances on the flange except the inner wall of the screw hole 5, including the back side of the flange 1, the side side of the flange 2, the front side of the flange 3 and the surface of the sealing boss.

[0043] 3) Pre-processing of the flange base: Carry out turning processing on the part of the flange to be coated. The surface roughness after processing is 2.2-2.8 μm, and the transition fillet between the end face and the side of the sealing boss is R1. 0, other transition fillets are R1.5.

[0044] 4) Plasma spraying:

[0045] ①Sandblasting pretreatment: use 100# corundum sand to blast the part to be sprayed, the surface cleanliness is Sa3 level, and the roughness is 50-75μm.

[0046] ②Adopt commercially available 0wt% TiO with a micron structure and a pa...

Embodiment 2

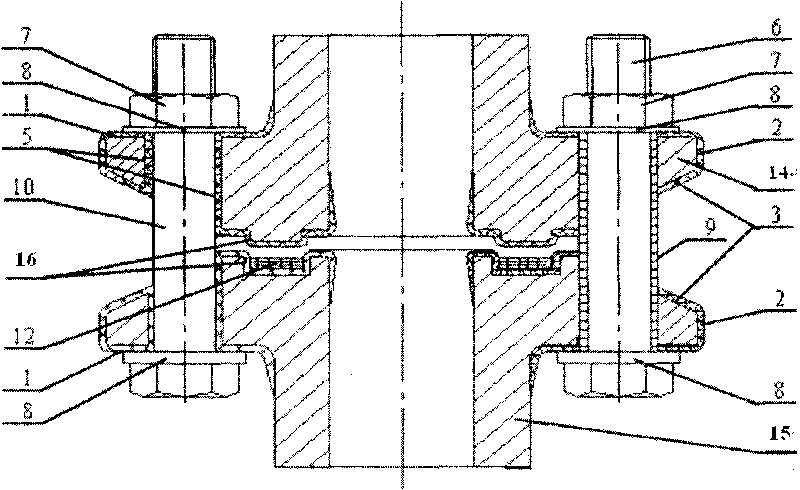

[0050] Take the ceramic insulating coating of the concave flange of the steel pipe section as an example.

[0051] 1) Coating composition: select 20wt% TiO 2 +80wt%Al 2 o 3 .

[0052] 2) Coating position: all appearances of the flange including the inner wall 5 of the bolt hole, that is, the rear face of the flange 1, the side face of the flange 2, the front face of the flange 3, the surface of the sealing groove and the inner wall of the screw hole 5;

[0053] 3) Flange substrate pre-processing: Carry out turning processing on the part of the flange to be coated, the surface roughness after processing is 2.0-2.6 μm, and the transition fillet between the end face and the side of the sealing groove is R1.0 , other transition fillets are R1.5.

[0054] 4) Plasma spraying:

[0055] ①Sandblasting pretreatment: use 100# corundum sand to carry out sandblasting treatment on the parts to be sprayed, the surface cleanliness is Sa3 level, and the roughness is 50-75μm.

[0056] ②Ad...

Embodiment 3

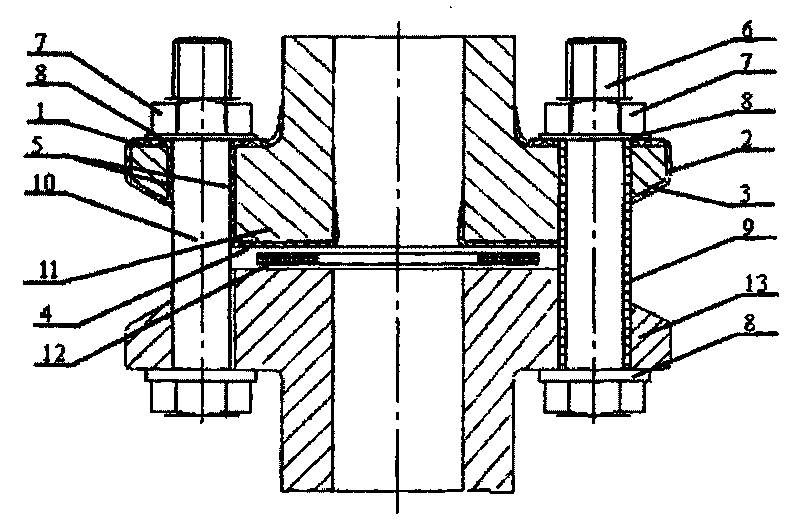

[0060] Take the ceramic insulating coating of the flat flange of the water outlet of the TC4 titanium alloy valve as an example.

[0061] 1) Coating composition: select 50wt% TiO 2 +50wt%Al 2 o 3 .

[0062] 2) Coating position: all exterior surfaces of the flange including the inner wall 5 of the bolt hole, including the rear face 1 of the flange, the side face 2 of the flange, the front face 3 of the flange, the sealing end face 4 and the inner wall 5 of the screw hole.

[0063] 3) Flange substrate pre-processing: Carry out turning processing on the part of the flange to be coated. The surface roughness after processing is 1.8-2.2 μm, and all rounded corners are R1.5.

[0064] 4) Plasma spraying:

[0065] ①Sandblasting pretreatment: use 100# corundum sand to blast the parts to be sprayed, the surface cleanliness is Sa3 level, and the roughness is 50-75μm.

[0066] ②Adopt 50wt% TiO with common commercially available micron structure and particle size of 40-75μm 2 +50wt%A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com