Method for manufacturing microstructure fiber

A technology of a microstructure optical fiber and a manufacturing method, which is applied in the directions of cladding optical fiber, optical waveguide light guide, etc., can solve the problems of complex manufacturing process and low stability, and achieve the effects of simple process, reduced manufacturing cost, and reduced manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

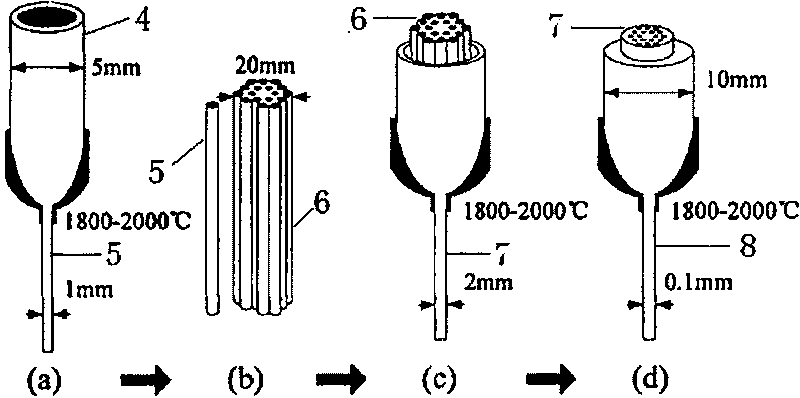

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as Figure 4 Shown, a kind of manufacturing method of microstructure optical fiber comprises the following steps:

[0024] A. If Figure 4 As shown in (a), select a quartz or crystal fiber rod ① with a diameter of 10-20mm. Crystal fiber rod ① can use sapphire rod, sapphire hardness is very high. The diameter of the quartz or crystal fiber rod can be selected arbitrarily, and the optimum diameter range is 10-20 mm, and the diameter selected in this embodiment is 10 mm.

[0025] B. If Figure 4 As shown in (b), the corresponding processing conditions of the laser are set, and radial holes are drilled in the selected quartz or crystal fiber rod. The laser processing can use a near-ultraviolet laser or a femtosecond laser. Near-ultraviolet lasers, whose output laser wavelength range is in the near-ultraviolet spectral region (2000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com