Organic light emitting diode of alkali metal carbonate-doped organic electron injecting layer

An alkali metal carbonate, light-emitting diode technology, applied in circuits, electrical components, electrical solid devices, etc., to reduce the production cost and improve the effect of the micro-cavity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically described with reference to examples, but the present invention is not limited only to the exemplified examples.

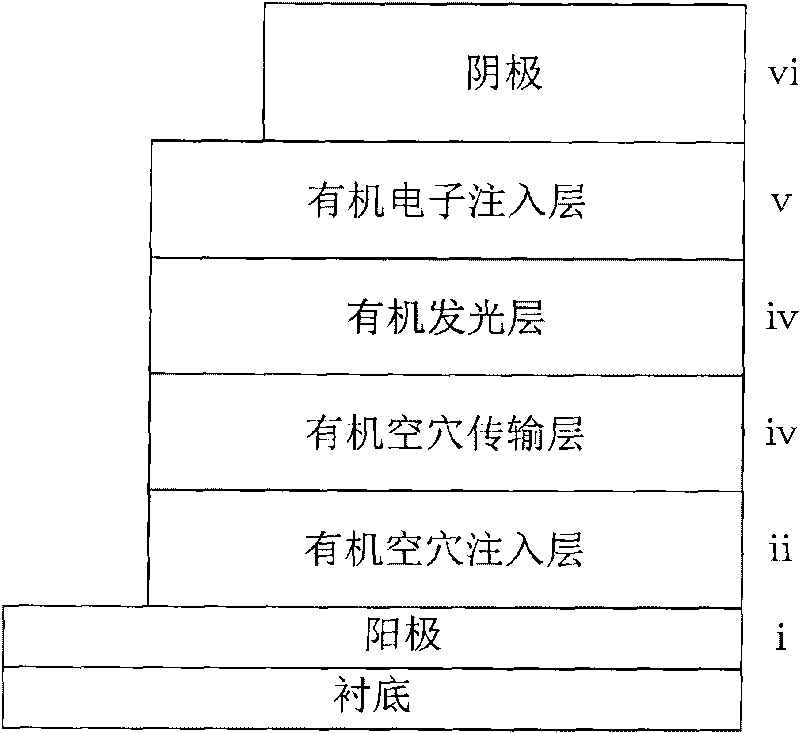

[0024] refer to figure 1 , the organic light emitting diode structure is composed of an anode i, an organic hole injection layer ii, an organic hole transport layer iii, an organic light emitting layer iv, an organic electron injection layer v, and a cathode vi on a glass substrate.

[0025] The glass covered with indium tin oxide (hereinafter referred to as ITO glass, produced by CSG) is used as the anode substrate, the thickness of the ITO layer is 180nm, and the surface resistance is less than 10 ohms per square. Then the ITO glass was cut into small pieces of 4×4cm2, cleaned in acetone, ethanol, and deionized water in an ultrasonic cleaner, each solvent was washed twice for 10 minutes each time, and then dried with nitrogen. The dried ITO glass was treated in a UV-ozone device for 10 minutes. Then put the ITO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com