Sewage treatment filtercake by taking river sludge as raw material and manufacturing method

A technology for sewage treatment and raw materials, applied in water/sludge/sewage treatment, biological water/sewage treatment, separation methods, etc. Granular filter material output and other issues, to achieve the effect of rough surface, low cost, high performance price ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Use riverside silt and mica powder as raw materials. The ratio is: 80kg of riverside sludge, 15kg of fly ash, 5kg of steelmaking red mud, plus 2kg of bulking agent (mica powder). The production process is as follows: 1. Add 80kg of riverside sludge, 15kg of fly ash, 5kg of steelmaking red mud and 2kg of mica powder into the mixing kettle for 20 minutes, then add 28kg of water and 2kg of polyacrylamide solution (concentration 0.2%) were mixed and artificially granulated. 2. Put the pellets into a sintering furnace with a temperature of 400°C, heat and dry for 45 minutes, and then heat up and sinter to create pores. When the temperature was raised to 1050°C, the temperature was kept for 15 minutes. 3. After the sintered ceramsite is out of the furnace, it is naturally cooled to room temperature.

Embodiment 2-5

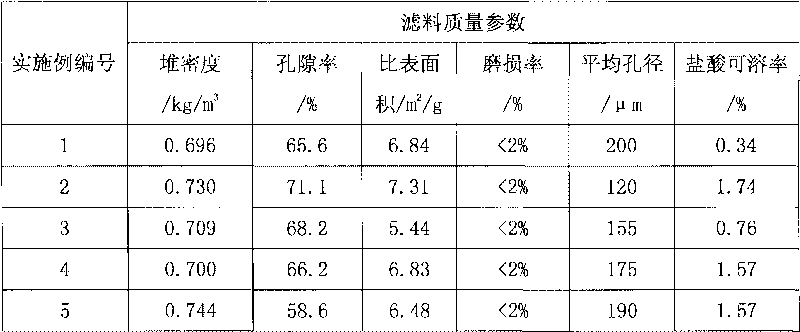

[0019] The difference between embodiment 2 and embodiment 1 is that the consumption of mica powder is reduced, the consumption of all the other raw materials is constant, and the operating conditions are constant. The difference between Example 4 and Example 1 is that the amount of fly ash is reduced and the amount of steelmaking red mud is increased. The difference between Example 5 and Example 1 is that the raw material is all riverside sludge, and the rest remain unchanged. In Example 3, the bulking agent was changed from mica powder to charcoal powder, and in Example 4, the bulking agent was changed from mica powder to waste plastic powder, and the amount of raw materials and operating conditions were unchanged, which was the same as in Example 1. The raw material proportions of Examples 1-5 are shown in Table 1, and the physical and chemical performance indexes of the corresponding filter materials are shown in Table 2.

[0020] Table 1

[0021] Example number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com