Miscellaneous cereal-containing compound ham sausages and method for preparing same

A technology for ham sausage and miscellaneous grains, applied in the field of food processing, can solve the problem of no oat, buckwheat sausage sausage, etc., and achieve a comprehensive nutritional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

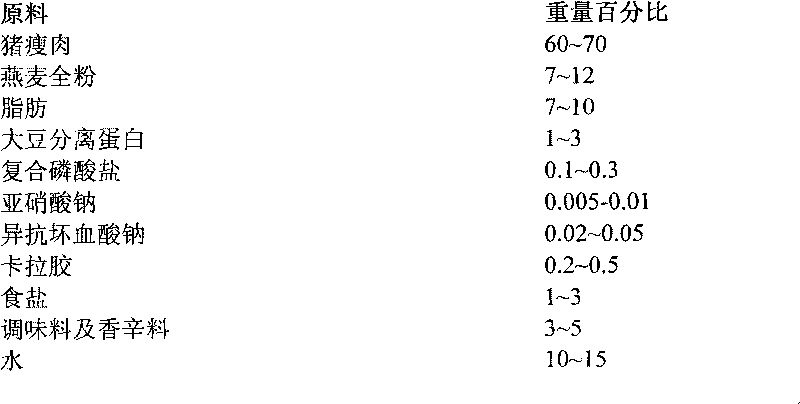

[0023] Example 1: Oatmeal compound ham sausage

[0024] Ingredients:

[0025] Pork lean meat 61kg, fat 8kg, soybean protein isolate 1.8kg, compound phosphate 0.2kg, sodium nitrite 0.008kg, sodium erythorbate 0.042kg, carrageenan 0.35kg, salt 2.4kg, seasoning and spices 3.2kg, whole oat powder 11kg, water 12kg.

[0026] Preparation method:

[0027] 1. Grind the oats with a plant grinder and pass through a 60-mesh sieve for later use;

[0028] 2. Grind pork lean meat and fat into minced meat with a meat grinder for later use;

[0029] 3. Mix the oat flour and other materials with water and put them into the meat paste, and then stir them evenly with a high-speed chopping machine;

[0030] 4. Pour the evenly stirred minced meat into the plastic casing with the help of a sausage stuffer, and seal and tie the two ends;

[0031] 5. Put the obtained semi-finished product into a boiling water bath and cook for 30 minutes, so that the central temperature reaches 72°C to obtain the...

Embodiment 2

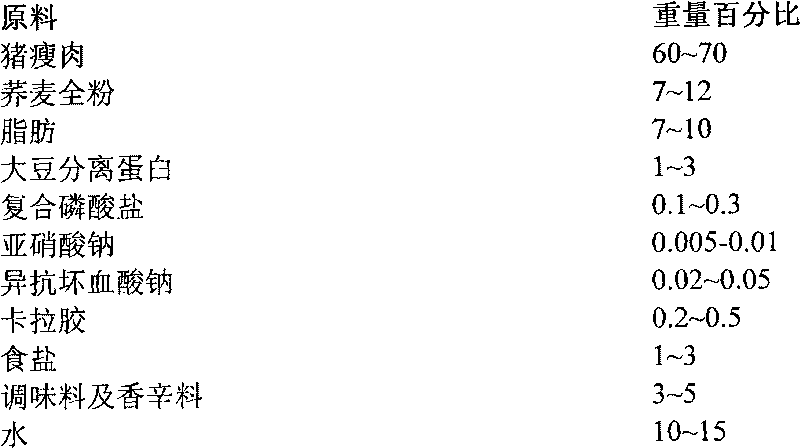

[0032] Example 2: Buckwheat compound ham sausage

[0033] Ingredients:

[0034] Pork lean meat 60kg, fat 7.5kg, soybean protein isolate 1.5kg, compound phosphate 0.2kg, sodium nitrite 0.008kg, sodium erythorbate 0.042kg, carrageenan 0.35kg, salt 2.4kg, seasoning and spices 3kg, whole buckwheat powder 11.5kg, water 13.5kg.

[0035] Preparation method:

[0036] 1. Pulverize the buckwheat with a plant grinder and pass through a 90-mesh sieve for later use;

[0037] 2. Grind pork lean meat and fat with a meat grinder for later use;

[0038] 3. Mix the buckwheat flour and other materials with water, put them into the minced meat, and then stir them evenly with a high-speed chopping machine;

[0039] 4. Pour the evenly stirred minced meat into the plastic casing with the help of a sausage stuffer, and seal and tie the two ends;

[0040] 5. Put the obtained semi-finished product into a boiling water bath and cook for 30 minutes, so that the central temperature reaches 72°C to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com