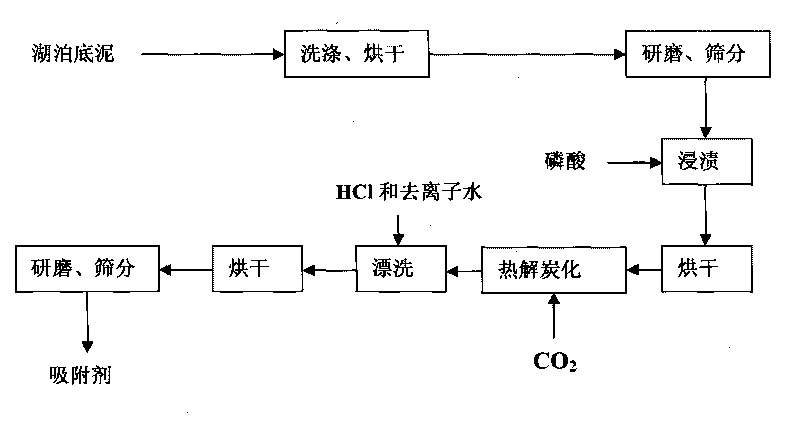

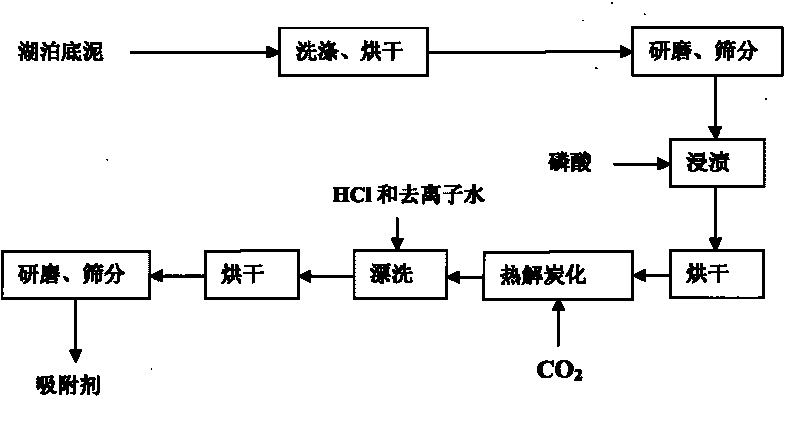

Method for preparing heavy metal adsorbent by carbonizing lakebed sludge

A technology of adsorbent and heavy metal, which is applied in the field of resource utilization of lake sediment to achieve the effect of improving performance, good activation effect and good adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Retrieve the sediment of the lake sediment, pour out the supernatant, wash 3 times with distilled water, pre-dehydrate it at room temperature for 8h, then dry it at 105℃ for 12h, then grind it, pass through a 60 mesh sieve, and take the lower fraction Add 20g of lake bottom mud to 60g of phosphoric acid solution with a concentration of 5mol / L, heat it in a 60℃ water bath for 12 hours, pour the upper layer of liquid, and put it in an oven at 105℃ for 24 hours, take it out and put it into the quartz in a high-temperature furnace In the tube reactor, the flow rate is 80mL / min CO 2 In the atmosphere, pyrolyze and carbonize at a temperature of 500°C for 60 minutes. The pyrolysis carbonized product is first washed with 3mol / L HCl solution many times to remove impurities in the carbonized product, and then rinsed with deionized water above 70°C until the pH of the water is greater than 6, and then dried at 105°C for 24h, and cooled After grinding and passing through a 60-mesh s...

Embodiment 2

[0043] Retrieve the sediment of the lake sediment, pour out the supernatant, wash it 3 times with distilled water, pre-dehydrate it at room temperature for 8 hours, then dry it at 105°C for 12 hours, then grind it, pass through a 60 mesh sieve, and take the lower fraction Add 20g of lake bottom mud to 80g phosphoric acid solution with a concentration of 5mol / L, heat it in a 60℃ water bath for 12 hours, pour the upper layer of liquid, and then put it in an oven at 105℃ to dry for 24 hours, take it out and put it into the quartz in a high-temperature furnace In the tube reactor, the flow rate is 80mL / min CO 2 In the atmosphere, pyrolyze and carbonize at 600°C for 60 minutes. The pyrolysis carbonized product is first washed with 3mol / L HCl solution for many times to remove impurities in the carbonized product, and then rinsed with deionized water above 70°C until the pH of the water is greater than 6, and then dried at 105°C for 24h, and cooled After grinding and passing through a...

Embodiment 3

[0045] Retrieve the sediment of the lake sediment, pour off the supernatant, wash 3 times with distilled water, pre-dehydrate it at room temperature for 8h, then dry it at 105℃ for 12h, then grind it, pass through a 60 mesh sieve, and take the lower fraction Add 20g of lake bottom mud to 100g of phosphoric acid solution with a concentration of 5mol / L, heat it in a 60℃ water bath for 12 hours, pour the upper layer of liquid, and put it in an oven at 105℃ to dry for 24 hours, take it out and put it into the quartz in a high-temperature furnace In the tube reactor, the flow rate is 80mL / min CO 2 In the atmosphere, pyrolyze and carbonize at 700°C for 60 minutes. The pyrolysis carbonized product is first washed with 3mol / L HCl solution for many times to remove impurities in the carbonized product, and then rinsed with deionized water above 70°C until the pH of the water is greater than 6, and then dried at 105°C for 24h, and cooled After grinding and passing through a 60-mesh sieve,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com