Method for expanding titanium T-shaped pipe

A technology of bulging and pipe fittings, applied in the field of bulging of titanium T-shaped pipe fittings, can solve the problems of high product cost, leakage, application restrictions, etc., and achieve the effect of improving service life, good economic benefits, and meeting market needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

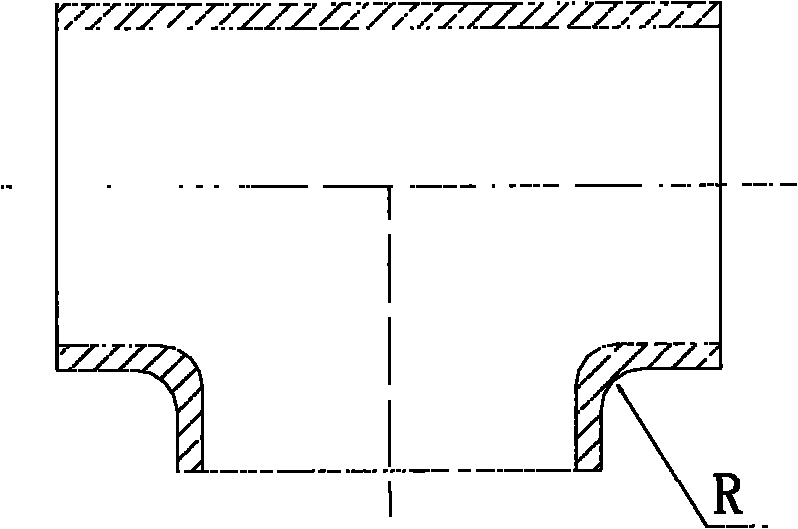

[0023] A thin-walled titanium T-shaped pipe fitting, which requires the quality of the pipe fitting to meet the requirements of Q / 725-1190-2008 "Titanium Butt Welding Seamless Pipe Fittings". The present invention takes material: Φ55×1.5mm, TA2 seamless pipe as the blank, the length of the blank is 280mm, using different forming processes and lubricants to form ships and chemical industry Φ55×Φ55×1.5, T-shaped pipe fittings as an example, the comparison test results are shown in Table 1.

[0024] Table 1

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com