Method for preparing formamidine acetate

A technology for formamidine acetate and acetate, applied in the field of preparing formamidine acetate, can solve the problems of being unsuitable for industrialized large-scale production and high cost, and achieve the effects of low cost, little environmental pollution and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

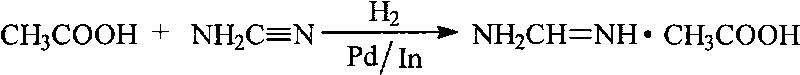

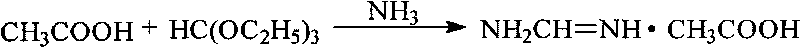

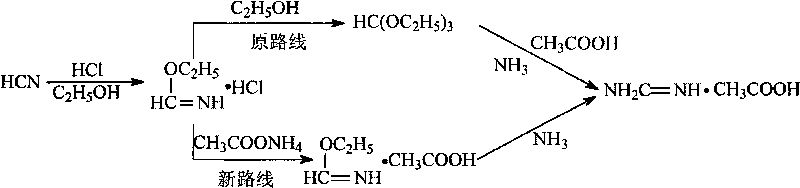

Method used

Image

Examples

Embodiment 1

[0023] In a 500ml reaction bottle, add 200ml of solvent and 46g of ethanol, stir and cool down to below -15°C, add 27g of hydrocyanic acid, start to pass in 40g of dry hydrogen chloride gas, control the temperature not to exceed -5°C for 6 hours, filter to obtain Urethane hydrochloride.

[0024] Dissolve 85g of ammonium acetate in 200ml of absolute ethanol, add the ethyl imidoformate hydrochloride obtained in the previous step in portions below -5°C, stir vigorously for 1 hour, raise the temperature to room temperature for 1 hour, then raise the temperature to 45°C to continue After reacting for 1 hour, white precipitated ammonium chloride gradually precipitated, cooled down, and filtered.

[0025] The filtrate is heated to reflux, and at the same time, dry ammonia gas is introduced at a certain speed for 1.5 to 2 hours, and about 35g of ammonia gas is introduced, and white solids are gradually precipitated in the reaction bottle. After cooling down, filtering, and washing wit...

Embodiment 2

[0027] In a 500ml reaction bottle, add 200ml of solvent and 37g of methanol, stir and cool down to below -20°C, add 27g of hydrocyanic acid, start to pass in 42g of dry hydrogen chloride gas, control the temperature not to exceed -0°C for 8 hours, filter to obtain Methyl carbamate hydrochloride.

[0028] Dissolve 93g of ammonium acetate in 200ml of anhydrous methanol, add the methyl imidoformate hydrochloride obtained in the previous step in portions below -5°C, stir vigorously for 1 hour, raise the temperature to room temperature and react for 2 hours, then raise the temperature to 40°C to continue After reacting for 1 hour, white precipitated ammonium chloride gradually precipitated, cooled down, and filtered.

[0029] The filtrate is heated to reflux, and at the same time, dry ammonia gas is introduced at a certain speed for 2 to 2.5 hours, and about 85g of ammonia gas is introduced, and a white solid is gradually precipitated in the reaction bottle. After cooling down, fil...

Embodiment 3

[0031] Into a 500ml reaction bottle, add 200ml of solvent and 46g of ethanol, stir and cool down to below -5°C, add 27g of hydrocyanic acid, start to pass in 40g of dry hydrogen chloride gas, control the temperature not to exceed 0°C for 6 hours, filter to obtain imine Ethyl formate hydrochloride.

[0032] Dissolve 78g of ammonium acetate in 200ml of absolute ethanol, add the ethyl imidoformate hydrochloride obtained in the previous step in portions below -5°C, stir vigorously for 1 hour, raise the temperature to room temperature for 1 hour, and then raise the temperature to 45°C to continue After reacting for 1 hour, white precipitated ammonium chloride gradually precipitated, cooled down, and filtered.

[0033] The filtrate is heated to reflux, and at the same time, dry ammonia gas is introduced at a certain speed for 1.5 to 2 hours, and about 45g of ammonia gas is introduced, and white solids are gradually precipitated in the reaction bottle. After cooling down, filtering, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com