Method for preparing polyvinyl chloride resin with reduced leather diaphragm and improved porosity

A polyvinyl chloride resin and porosity technology, which is applied in the field of polyvinyl chloride resin to reduce the film and increase the porosity, can solve the problems of difficult to control the granulation process, coarse resin particles, coarse resin particles, etc., and achieve the concentration of particle size distribution, The effect of high porosity and regular particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

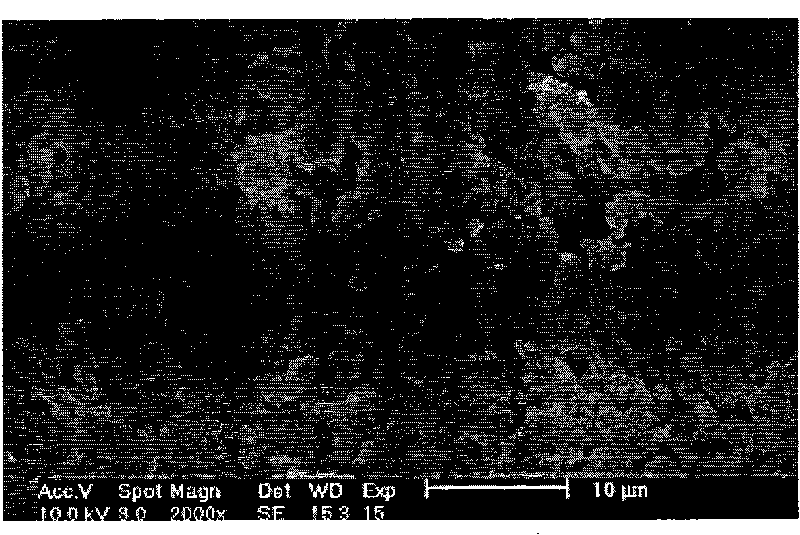

Image

Examples

Embodiment 1

[0053] The polymerization reaction is stirred as a two-leaf three-layer flat paddle, two symmetrical baffles, and a volume of 7M 3 in the kettle.

[0054] The technical conditions and process are briefly described as follows: First, 3.50t desalted water, 0.15kg dispersant A, 0.30kg dispersant B, 0.20kg 2-mercaptoethanol, 0.50kg NH 4 HCO 3 Put it into the kettle, add 2.30t of vinyl chloride monomer after pressure testing and vacuuming, inject 1.65kg of initiator bis-(2-ethylhexyl peroxydicarbonate) with a metering pump, start stirring, and maintain the power per unit volume at 0.80 kw / m 3 , the temperature is raised to 62°C to start constant temperature polymerization; when the polymerization conversion rate is 15%, add 0.20kg dispersant C with a metering pump, and the power per unit volume changes to 1.00kw / m 3 , continue polymerization; when the polymerization conversion rate is 35%, add 0.15kg dispersant C with a metering pump, and the power per unit volume changes to 1.2...

Embodiment 2

[0058] Change the add-on of dispersant A to 0.20kg, change the add-on of dispersant B to 0.50kg, when the polymerization conversion rate is 15%, add 0.15kg dispersant C with metering pump, when the polymerization conversion rate is 35%, Add 0.2kg dispersant C with metering pump, other technological conditions are with embodiment 1, and its test result is as follows: degree of polymerization is 800, and apparent density is 0.54 (g / ml), porosity 0.28 (ml / g), average particle size The diameter is 150.0 (μm), the distribution width is 0.710, and the film coverage is 40%.

Embodiment 3

[0060] When the polymerization conversion rate reaches 15%, the add-on of dispersant C becomes 0.20kg, and when the conversion rate reaches 35%, the add-on of powder C becomes 0.30kg, and other process conditions are with embodiment 1, and its test result is as follows: the degree of polymerization is 800, and the The apparent density is 0.56 (g / ml), the porosity is 0.24 (ml / g), the average particle size is 140.0 (μm), the distribution width is 0.710, and the film coverage is 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com