Method for reducing cane sugar content in molasses

A technology of molasses and sucrose, which is applied in the field of deep processing of soybean products through biodegradation, which can solve the problems of lack of production process and purification methods, high sucrose content, and low functionality, so as to increase product value, simplify the operation process, and improve functionality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, obtain the bacterial strain of fermentation and utilize this bacterial strain to ferment and produce high-quality oligosaccharide

[0031] 1. Obtain the fermented strain

[0032] 1. Seed activation: Take 50ml of seed activation medium into a 100ml Erlenmeyer flask, scrape the No. 1, No. 2, No. 7, No. 8 and No. 9 yeasts screened in the petri dish and preserved on the plate (smooth and plump colonies) Into the culture medium, 28 ℃, 180rpm air shaker for 48h. Among them, activation medium: glucose 10g, yeast extract 8.5g, NH 4 Cl 1.3g, MgSO 4 .7H 2 O 0.1g, Cacl 2 0.06g, 1000ml deionized water, sterilized at 0.08MPa for 15min.

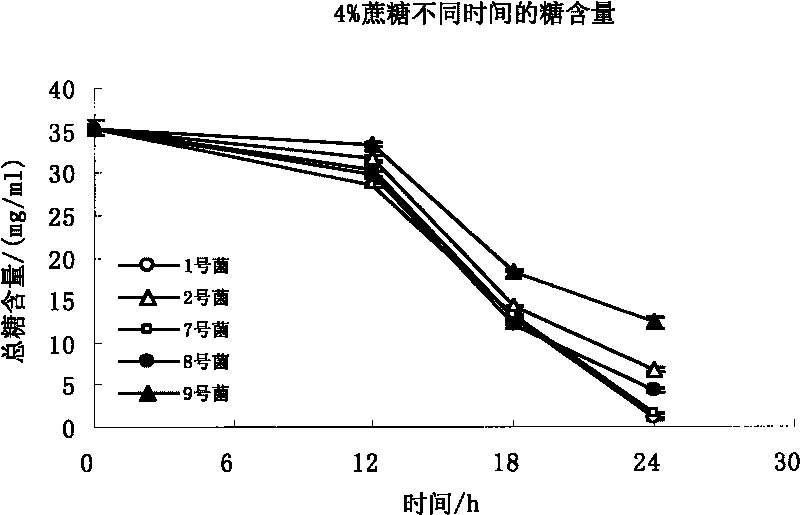

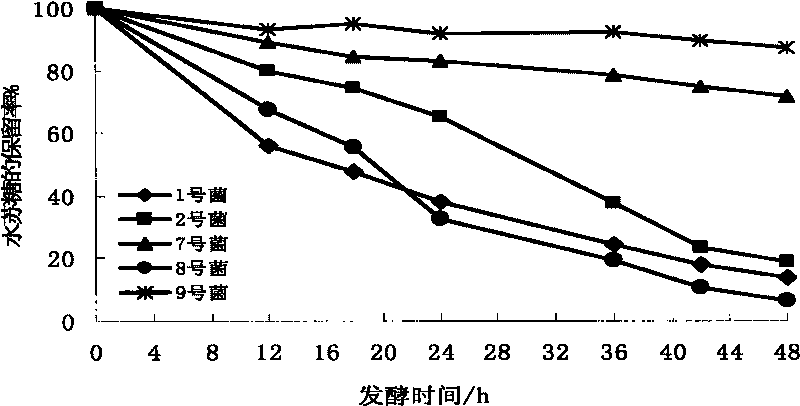

[0033] 2. Single-carbon culture: Take 2.5ml of activated medium (that is, the inoculum size is 5% (volume percentage)) and inoculate them into the following two 50ml fermentation broths respectively, cultivate them at 28°C and 180rpm, and then take samples at different times Determination of sugar content:

[0034] Sucrose as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com