Clean pulping process for straws by mechanical method

A technology of clean pulping and mechanical method, applied in pulping of cellulose raw materials, textiles and papermaking, papermaking, etc., can solve the problems of less than 10% comprehensive utilization rate, immature pulp of ammonia blasting technology biodegradation technology, environmental pollution, etc. , to achieve the effects of promoting local economic development, increasing farmers' income, and protecting the natural environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

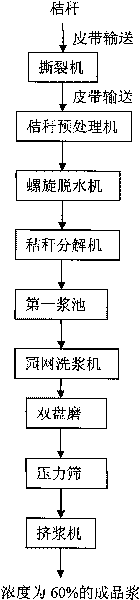

Image

Examples

Embodiment 1

[0014] 1) The straw is sent to the tearing machine with a conveyor belt, and the straw is cut into 3-5cm long filaments by the tearing machine, and 800 kg of water is added to each ton of straw through the outlet of the tearing machine for full wetting, and it is piled up for 48 hours. Natural saccharification of straw by accumulating the heat generated by itself;

[0015] 2) Transport the straw that has undergone natural sugar in step (1) to the straw pretreatment machine for wetting, swelling, and disintegration by a belt conveyor, and add water to the straw pretreatment machine to make the weight percentage concentration of the straw-water mixture Controlled at 9.5%, the straw pretreatment machine has a rotatable blade, which can further break down the straw;

[0016] 3) Transport the straw-water mixture that has been wetted, swelled, and disintegrated in step (2) to a screw dehydrator for dehydration, and when the water is dehydrated to a concentration of 38% by weight of ...

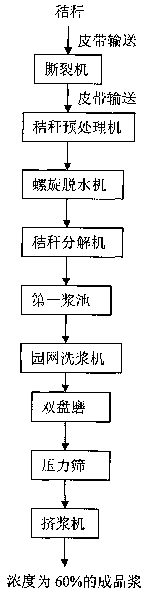

Embodiment 2

[0022] 1) The straw is fed into the tearing machine with a conveyor belt, and the straw is cut into filaments of 3-5 cm in length by the tearing machine, and 1000 kg of water is added to each ton of straw through the outlet of the tearing machine to fully wet the straw and piled up for 50 hours. Natural saccharification of straw by accumulating the heat generated by itself;

[0023] 2) Transport the straw that has undergone natural sugar in step (1) to the straw pretreatment machine for wetting, swelling, and disintegration by a belt conveyor, and add water to the straw pretreatment machine to make the weight percentage concentration of the straw-water mixture Controlled at 10%, the straw pretreatment machine has a rotatable blade, which can further break down the straw;

[0024] 3) Transport the straw-water mixture that has been wetted, swelled, and disintegrated in step (2) to a screw dehydrator for dehydration, and when the water is dehydrated to a concentration of 42% by w...

Embodiment 3

[0027] 1) The straw is sent to the tearing machine with a conveyor belt, and the straw is cut into 3-5cm long filaments by the tearing machine, and 900 kg of water is added to each ton of straw through the outlet of the tearing machine to fully wet it, and it is piled up for 49 hours. Natural saccharification of straw by accumulating the heat generated by itself;

[0028] 2) Transport the straw that has undergone natural sugar in step (1) to the straw pretreatment machine for wetting, swelling, and disintegration by a belt conveyor, and add water to the straw pretreatment machine to make the weight percentage concentration of the straw-water mixture Controlled at 9%, the straw pretreatment machine has a rotatable blade, which can further break down the straw;

[0029] 3) Transport the straw-water mixture that has been wetted, swelled, and disintegrated in step (2) to a screw dehydrator for dehydration, and when the water is dehydrated to a concentration of 40% by weight of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com