Method for manufacturing CVD silicon oxide capable of improving forming quality

A manufacturing method and technology of forming quality, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as undercutting is not very serious, photoresist is lifted, affecting the forming effect of CVD silicon oxide, etc. Reduced etch rate, improved adhesion, reduced undercut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

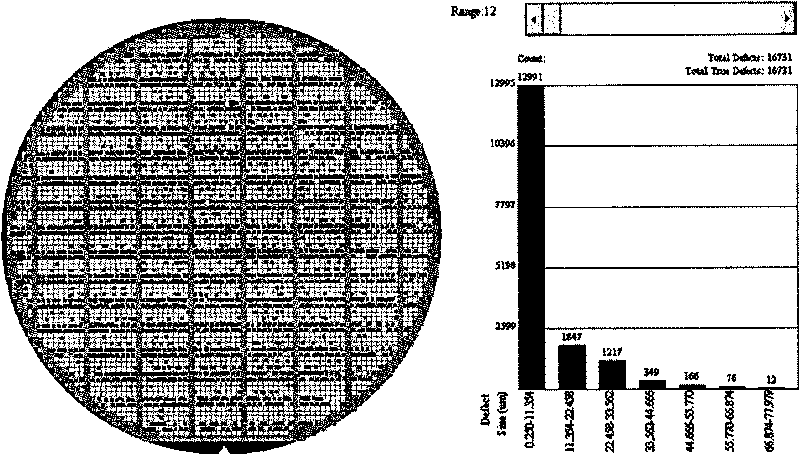

Image

Examples

Embodiment Construction

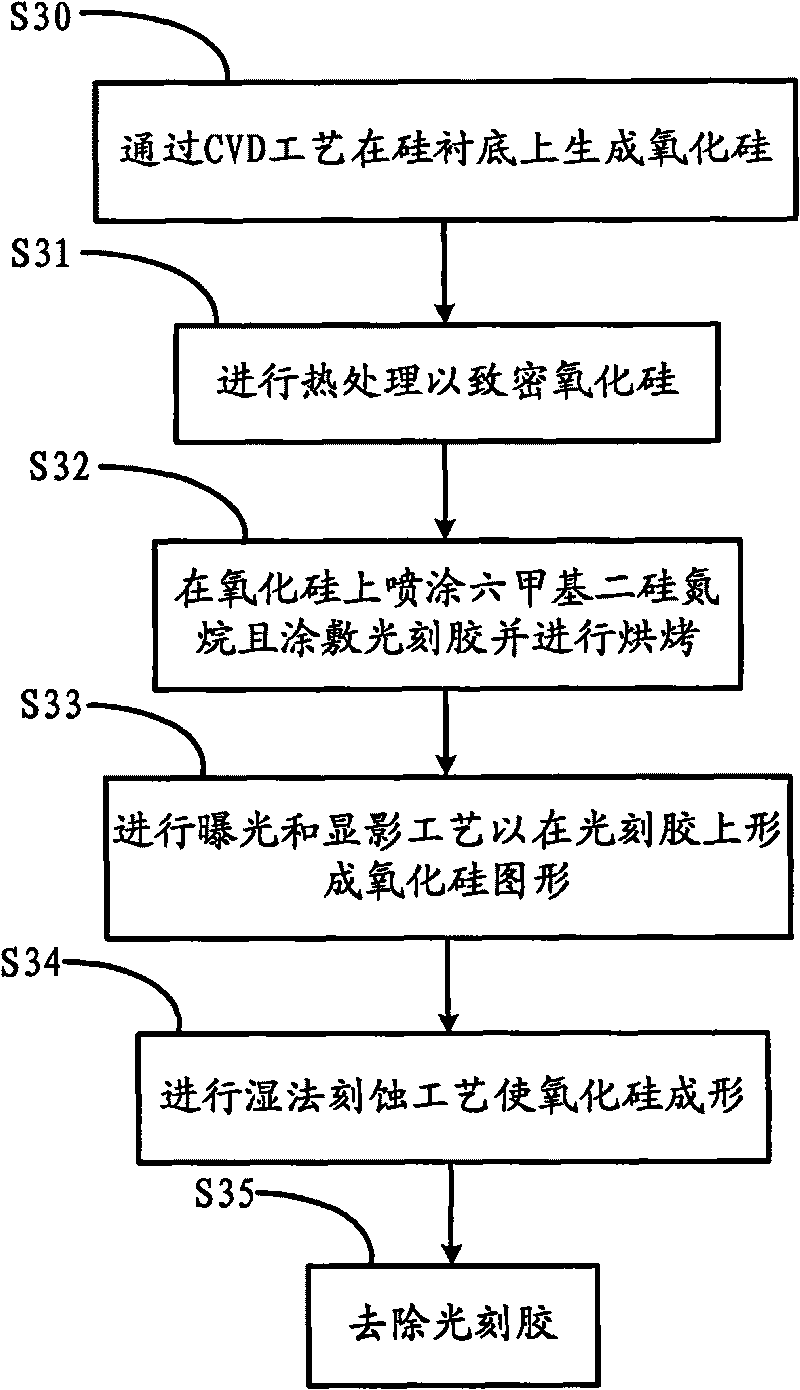

[0022] The CVD silicon oxide manufacturing method capable of improving forming quality of the present invention will be further described in detail below.

[0023] see image 3 , which shows the process flow of the CVD silicon oxide manufacturing method that can improve the forming quality of the present invention. As shown in the figure, the CVD silicon oxide manufacturing method that can improve the forming quality of the present invention first performs step S30, and the silicon substrate is formed by the CVD process. Silicon oxide is formed on the surface, and the CVD process is a low pressure chemical vapor deposition (LPCVD) process or an atmospheric pressure chemical vapor deposition (APCVD) process. In this embodiment, the CVD process is LPCVD.

[0024] Then continue to step S31, and perform heat treatment to densify silicon oxide. To improve efficiency, the heat treatment usually adopts rapid thermal processing (RTP). The processing temperature ranges from 800 to 900...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com