Preparation method of flavonoid glycosides in scutellaria baicalensis

A technology of flavonoid glycosides and baicalensis, applied in the field of separation of natural medicines, can solve the problems of low column efficiency, limitation of simultaneous separation of multiple compounds, high-throughput preparation of unfavorable compounds, etc., and achieves short cycle time, guaranteed reproducibility and stability. , good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

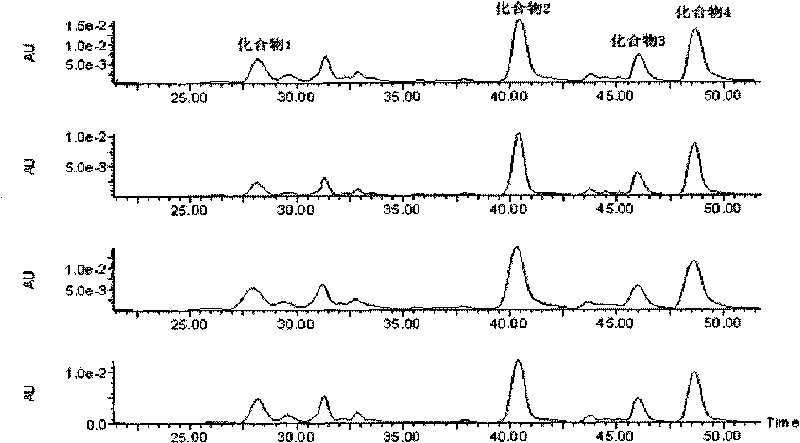

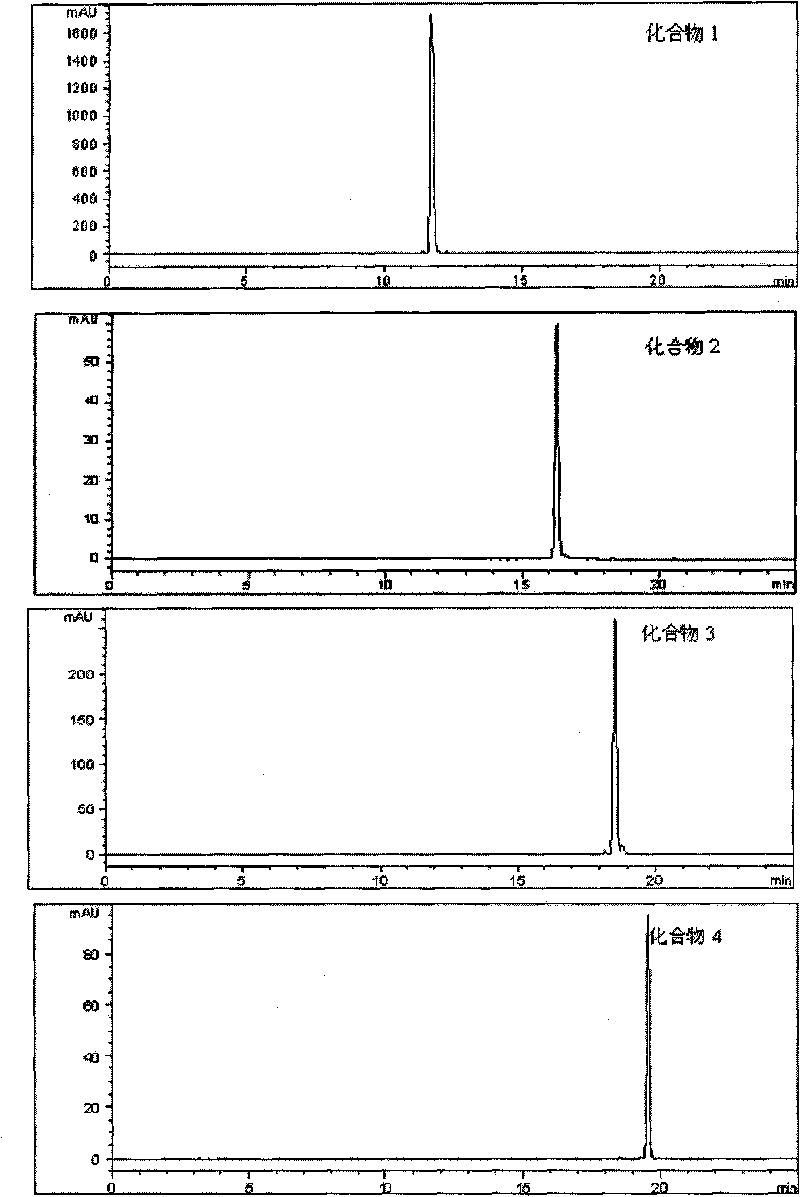

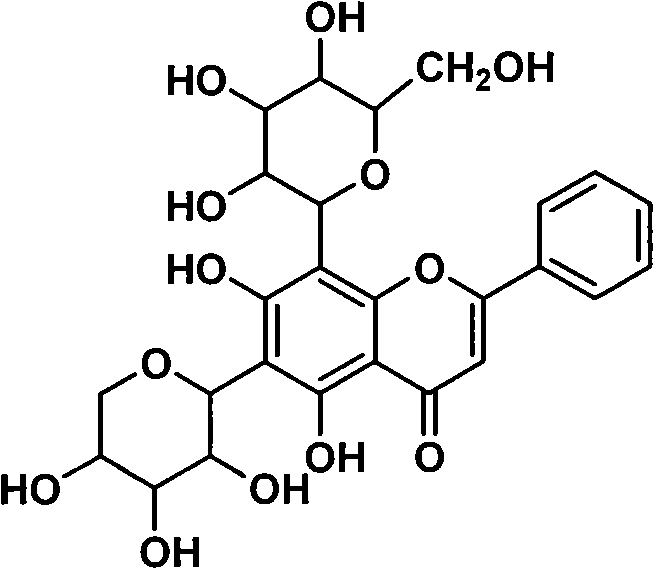

[0024] Embodiment 1: the preparation method of flavonoid glycosides in Scutellaria baicalensis

[0025] Crush the raw medicinal material of Scutellaria baicalensis, weigh 2 kg quantitatively, put it in a 20-liter extraction tank, add 20 liters of water to decoct for 1 hour, filter, and save the filtrate for later use, add 20 liters of water to the filter residue and decoct for 1 hour, filter, and the filtrate and the second Once combined, the filter residue was discarded. Concentrate the extract by rotary evaporation to 500 ml to obtain the water extract fraction of Scutellaria baicalensis. Add 710 milliliters of 95% ethanol to the concentrated solution, stir well, let stand at room temperature for 24 hours, filter, discard the filter residue, concentrate the filtrate to 300 milliliters, add 1600 milliliters of 95% ethanol to the concentrated solution, stir well, and let stand at room temperature for 24 hours hour, filter, filter residue is discarded, the filtrate is concentr...

Embodiment 2

[0044] Crush the raw medicinal material of Scutellaria baicalensis, weigh 4 kg quantitatively, put it in a 100-liter extraction tank, add 32 liters of water to decoct for 2 hours, filter, and save the filtrate for later use, add 32 liters of water to the filter residue and decoct for 2 hours, filter, and the filtrate and the second Once combined, the filter residue was discarded. The extract was concentrated to 800 ml by rotary evaporation to obtain the water extract fraction of Scutellaria baicalensis. Add 1370 milliliters of 95% ethanol to the concentrated solution, stir well, let stand at room temperature for 24 hours, filter, discard the filter residue, and concentrate the filtrate to 400 milliliters, add 2140 milliliters of 95% ethanol to the concentrated solution, stir well, and let stand at room temperature for 24 hours. hour, filter, filter residue is discarded, the filtrate is concentrated to no alcohol smell, and the concentrated solution is centrifuged through a hig...

Embodiment 3

[0048] Scutellaria baicalensis raw medicinal materials were pulverized, weighed 6 kg quantitatively, placed in a 100-liter extraction tank, added 36 liters of water and decocted for 3 hours, filtered, and the filtrate was stored for later use, and 36 liters of water were added to the filter residue and decocted for 3 hours, filtered, and the filtrate was mixed with the second Once combined, the filter residue was discarded. The extract was concentrated to 1200 ml by rotary evaporation to obtain the water extract fraction of Scutellaria baicalensis. Add 2050 milliliters of 95% ethanol to the concentrated solution, stir well, let stand at room temperature for 24 hours, filter, discard the filter residue, concentrate the filtrate to 900 milliliters, add 4800 milliliters of 95% ethanol to the concentrated solution, stir well, and let stand at room temperature for 24 hours hour, filtered, and the filter residue was discarded, the filtrate was concentrated until there was no alcohol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com