Method for removing proteins and pigments in ganoderma lucidum crude polysaccharide

A crude polysaccharide and protein technology, which is applied in the field of biological separation and purification, can solve the problems of unfavorable purification of polysaccharide bioactive substances and industrial production, huge consumption of organic solvents, and great injury to operators, so as to shorten the separation and purification time. , Linear amplification is easy, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

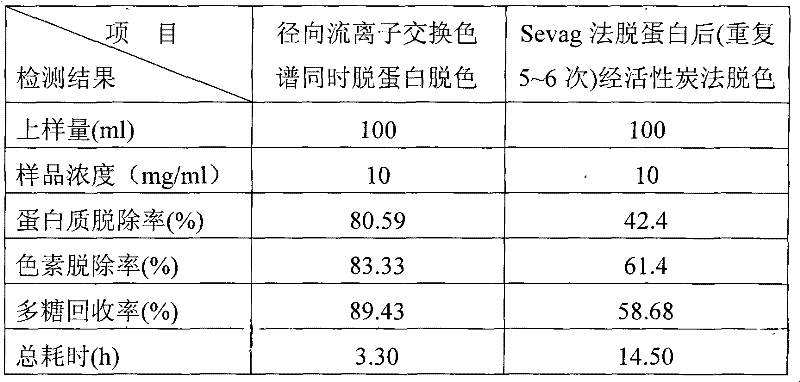

Image

Examples

Embodiment 1

[0028] 1. Sugar extraction: take 100g of Ganoderma lucidum, crush it, press Ganoderma lucidum, Add distilled water at a volume ratio of 1:15, place in a water bath at 95-100°C for 2 hours, and filter with suction. The filtrate is concentrated under reduced pressure, alcohol precipitation, centrifugation, and the precipitate is vacuum freeze-dried to obtain Ganoderma lucidum crude polysaccharide.

[0029] 2. Ion exchanger pretreatment: Soak the weakly basic anion exchanger A103S (Deqing Piaolaite (China) Co., Ltd.) in 0.5mol / L NaOH aqueous solution for 4 hours, wash with pure water until neutral, and then place it in 0.5 Soak in mol / L hydrochloric acid for 4 hours, wash with pure water until neutral, and finally soak in 0.5 mol / L NaOH aqueous solution for 4 hours, wash with pure water until neutral to obtain the desired anion exchanger.

[0030] 3. Packing: Pack the anion exchanger into a radial flow chromatographic column with a packing volume of 250ml in the radial column ...

Embodiment 2

[0036] Other operation is the same as embodiment 1, difference

[0037] In the extraction step of Ganoderma lucidum polysaccharide: the mass ratio of Ganoderma lucidum and water is 1:30, and the extraction time is 3 hours;

[0038] In the pretreatment step of the ion exchanger: the weakly basic anion exchanger A103S (Deqing Piao Lai Te (China) Co., Ltd.) was soaked in 1mol / L KOH aqueous solution for 2 hours, washed with pure water until neutral, and then placed in 1mol / L KOH solution. Soak in / L hydrochloric acid for 2 hours, wash with pure water until neutral, and finally soak in 1mol / L KOH aqueous solution for 2 hours, wash with pure water until neutral;

[0039] The protein removal rate obtained in the test was 79.65%, the pigment removal rate was 91.23%, and the polysaccharide recovery rate was 87.35%.

Embodiment 3

[0041] Other operations are the same as embodiment 1, the difference is:

[0042] In the ion exchanger pretreatment step: the kind of weakly basic anion exchanger used is A830 (Deqing Piao Wright (China) Co., Ltd.);

[0043] In the sample loading step: make Ganoderma lucidum crude polysaccharide into a 30mg / ml solution, centrifuge to obtain the supernatant, take 50ml of the supernatant and load it into a radial flow chromatography column at a flow rate of 2ml / min;

[0044] The protein removal rate obtained in the test was 74.06%, the pigment removal rate was 82.83%, and the polysaccharide recovery rate was 78.49%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com