Preparation method of NGF for cobra venom injection

A technology for cobra venom and injection, which is applied in the field of separation and purification of nerve growth factor, can solve the problems that it is difficult to scale up to pilot scale and production scale, small sample processing volume, and small activity loss, so as to shorten the separation and purification time and improve production efficiency High effect with little loss of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following examples are provided to further illustrate the invention, but it should not be considered to limit the details of the invention in the embodiments.

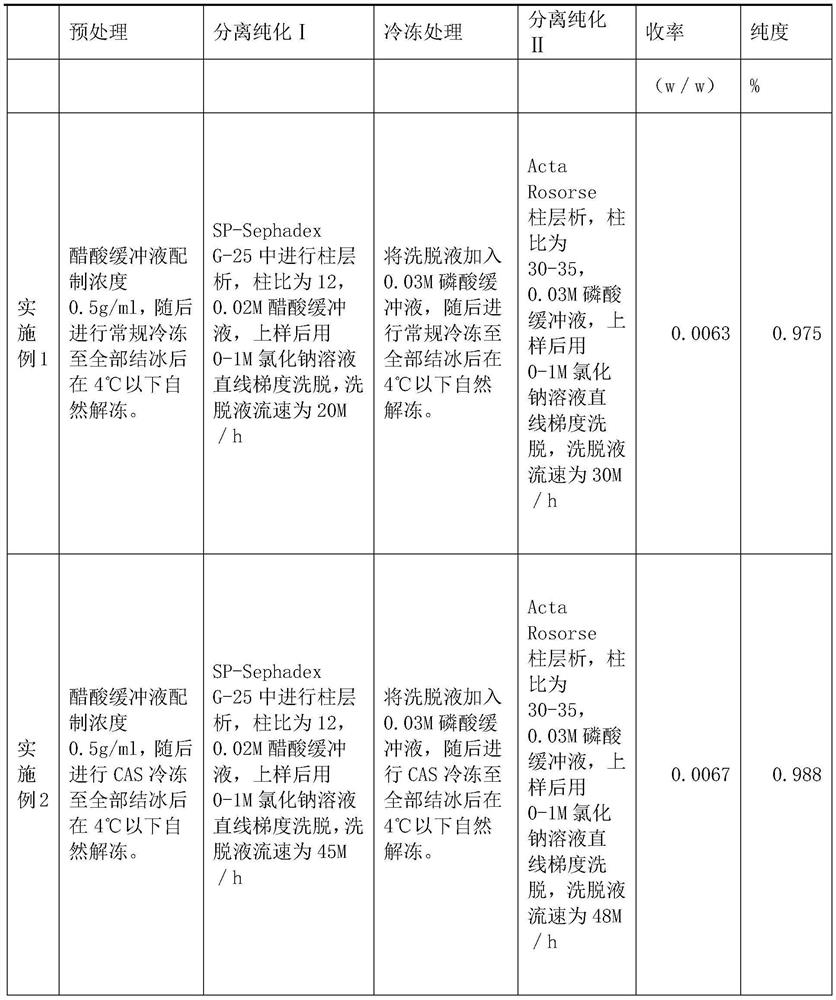

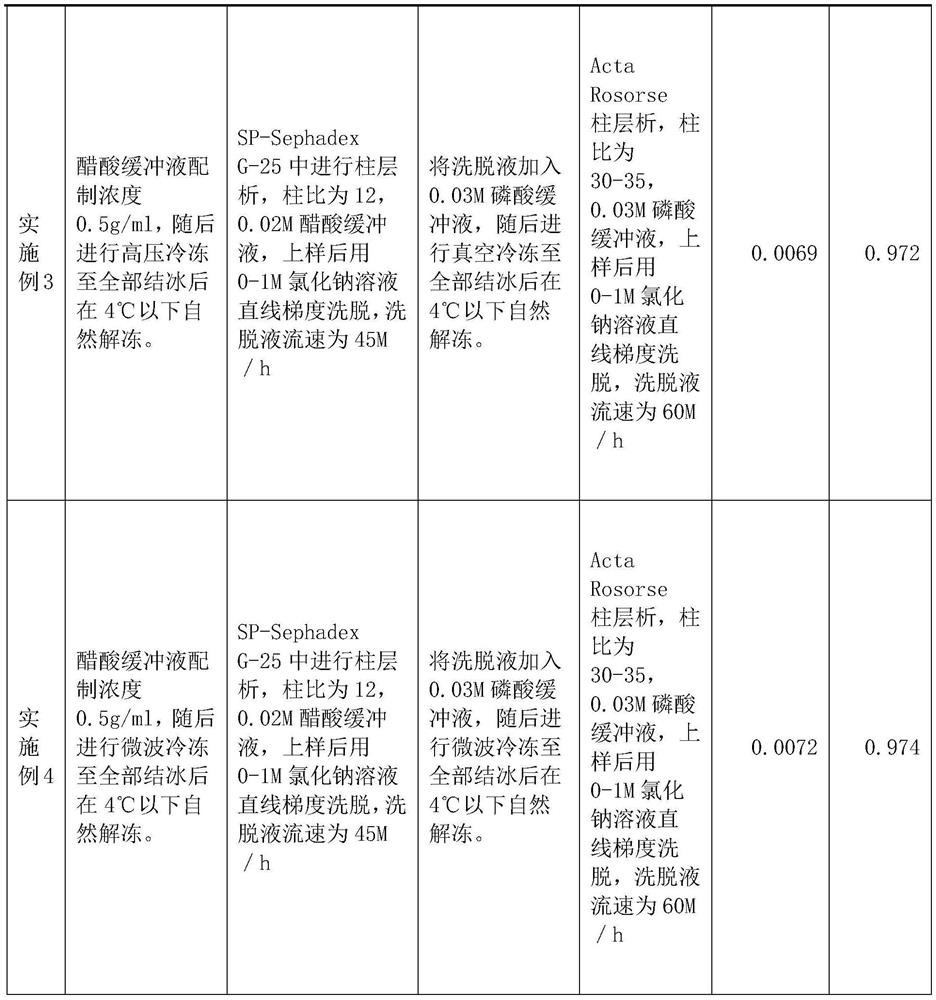

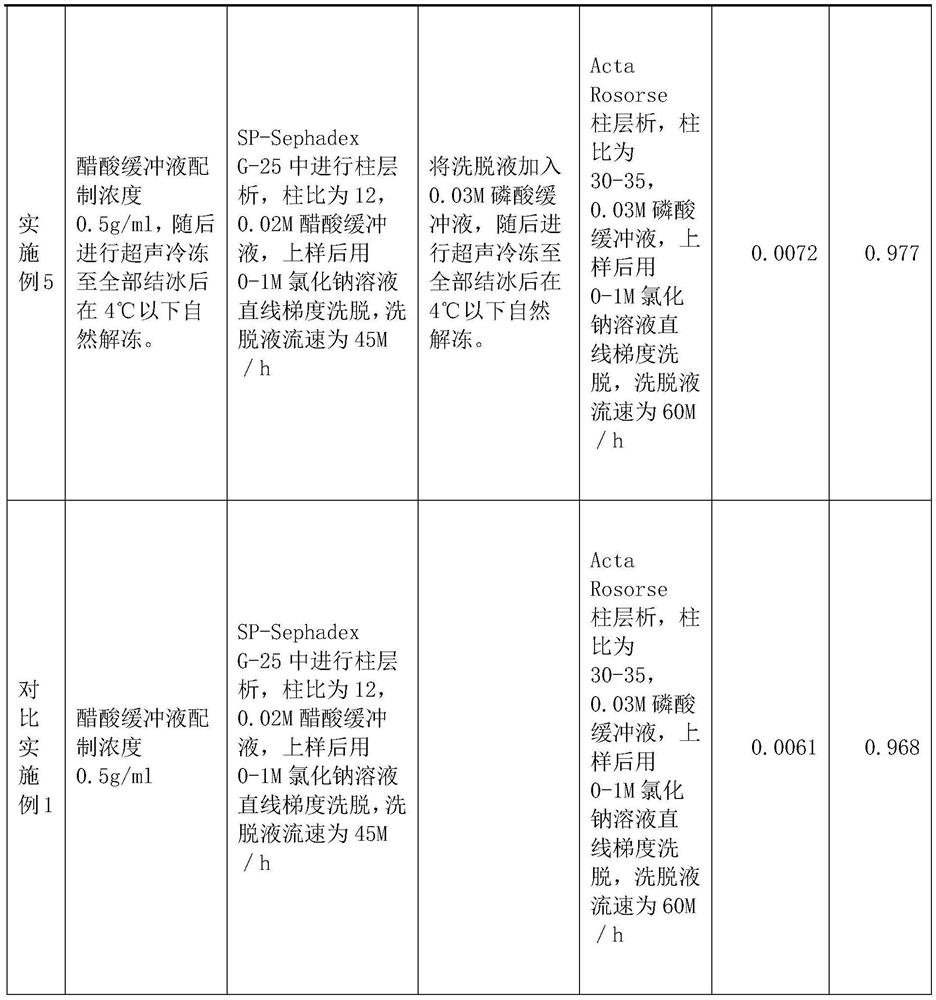

[0040]1. Comparison of several common gel chromatography

[0041] In order to better illustrate the effects and operation methods of the present invention, several common chromatographic methods are analyzed, in Examples 1-5 are exemplary embodiments of the present invention, compared to Examples 1-3 A comparative example of the freezing treatment, or a 1st freeze treatment link.

[0042] As can be seen from experimental data, after cryogenic, the yield of visual nerve growth factor is significantly improved, and can reach 0.6% or more, even more than 0.7%, and an average increase of more than 18%. At the same time, its purity is also increased, substantially higher than the method of processing that does not pass through freezing.

[0043] We believe that we believe that the freezing treatment through ice cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com