Method for preparing polymer/silver composite membrane by depositing dopamine

A polymer film and polymer technology, which is applied in the plating of superimposed layers, the device for coating liquid on the surface, the coating process of metal materials, etc., to achieve the effect of uniform and dense silver layer, easy operation and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

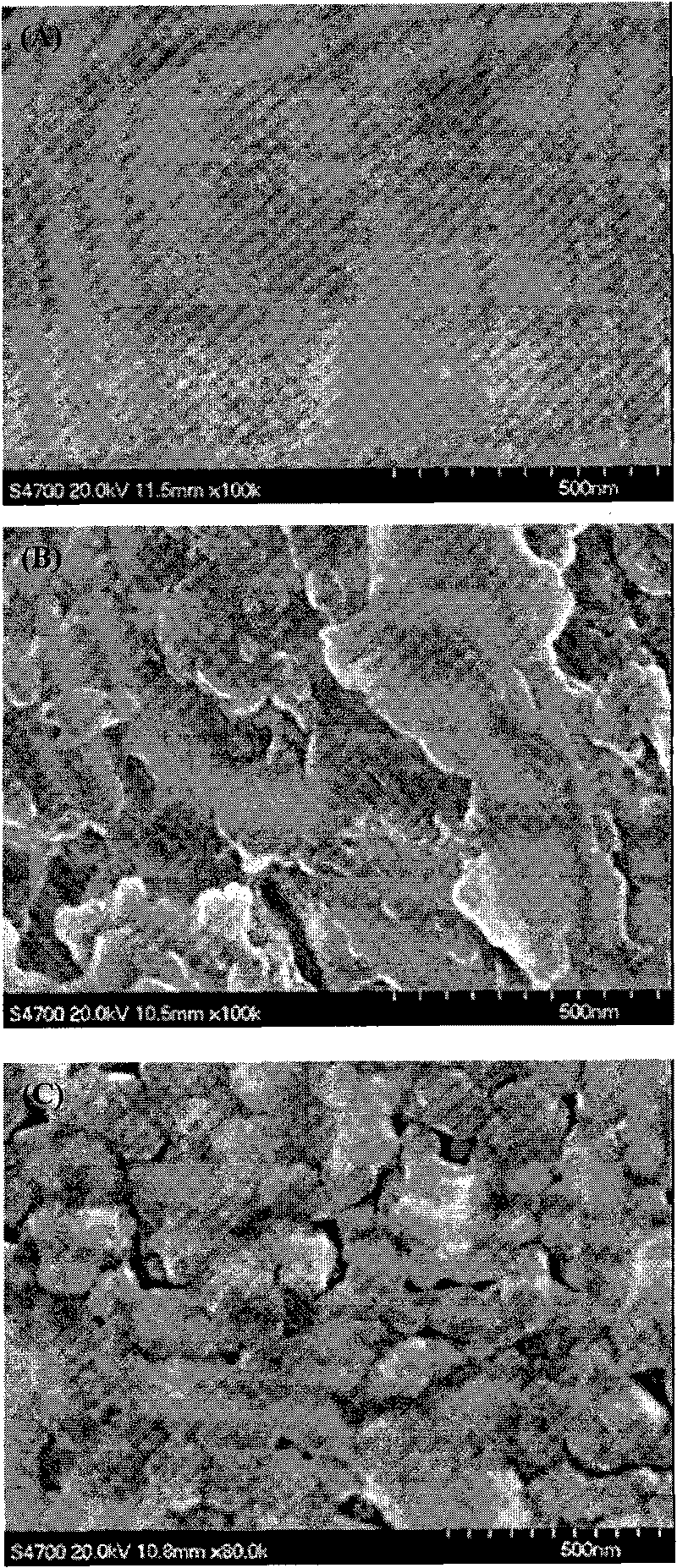

Image

Examples

Embodiment 1

[0024] 1) Prepare a dopamine aqueous solution with a mass fraction of 0.15mM / mL, adjust the pH to 8.5 with Tris acid and hydrochloric acid solution, soak a 1cm*1cm polyimide membrane in it, and stir at a stirring rate of 60 rpm for 24 hours After the stirring is finished, the polyimide film deposited with polydopamine is taken out, washed with distilled water, and dried in vacuum;

[0025] 2) Configure a silver nitrate solution with a mass fraction of 3wt%, and titrate with ammonia water until the precipitate just disappears completely to obtain a silver plating solution;

[0026] 3) Soak the polyimide film deposited with polydopamine in 10mL of silver plating solution, add 10mL of 6wt% glucose solution, and react for 10 minutes to obtain a polyimide / silver film with uniform metallic silver coverage on both sides Composite film.

[0027] It is determined that the film can conduct electricity, the resistance is between 1.5-2.0Ω, and the reflectivity is 95-98%.

[0028] The el...

Embodiment 2

[0030] 1) Prepare a dopamine aqueous solution with a mass fraction of 0.1mM / mL, and adjust the pH to 6 with Tris acid and hydrochloric acid solution, soak a 1cm*1cm polyimide membrane in it, and stir at a stirring rate of 30 rpm for 0.5 hours After the stirring is finished, the polyimide film deposited with polydopamine is taken out, washed with distilled water, and dried in vacuum;

[0031] 2) configure a silver nitrate solution with a mass fraction of 1 wt%, and titrate with ammonia water until the precipitate just disappears completely to obtain a silver plating solution;

[0032] 3) Soak the polyimide film deposited with polydopamine in 100mL silver plating solution, add 10mL of 1wt% glucose solution, and react for 1 minute to obtain a polyimide / silver composite film with uniform metallic silver coverage on both sides. membrane.

Embodiment 3

[0034] 1) Prepare a dopamine aqueous solution with a mass fraction of 0.3mM / mL, adjust the pH to 10 with Tris acid and hydrochloric acid solution, soak a 1cm*1cm polyimide membrane in it, and stir at a stirring rate of 100 rpm for 36 hours After the stirring is finished, the polyimide film deposited with polydopamine is taken out, washed with distilled water, and dried in vacuum;

[0035] 2) configure a silver nitrate solution with a mass fraction of 6wt%, and titrate it with ammonia water until the precipitate just disappears completely to obtain a silver plating solution;

[0036] 3) Soak the polyimide film deposited with polydopamine in 10mL of silver plating solution, add 10mL of 4wt% glucose solution, and react for 10 minutes to obtain a polyimide / silver film with uniform metallic silver coverage on both sides. Composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com