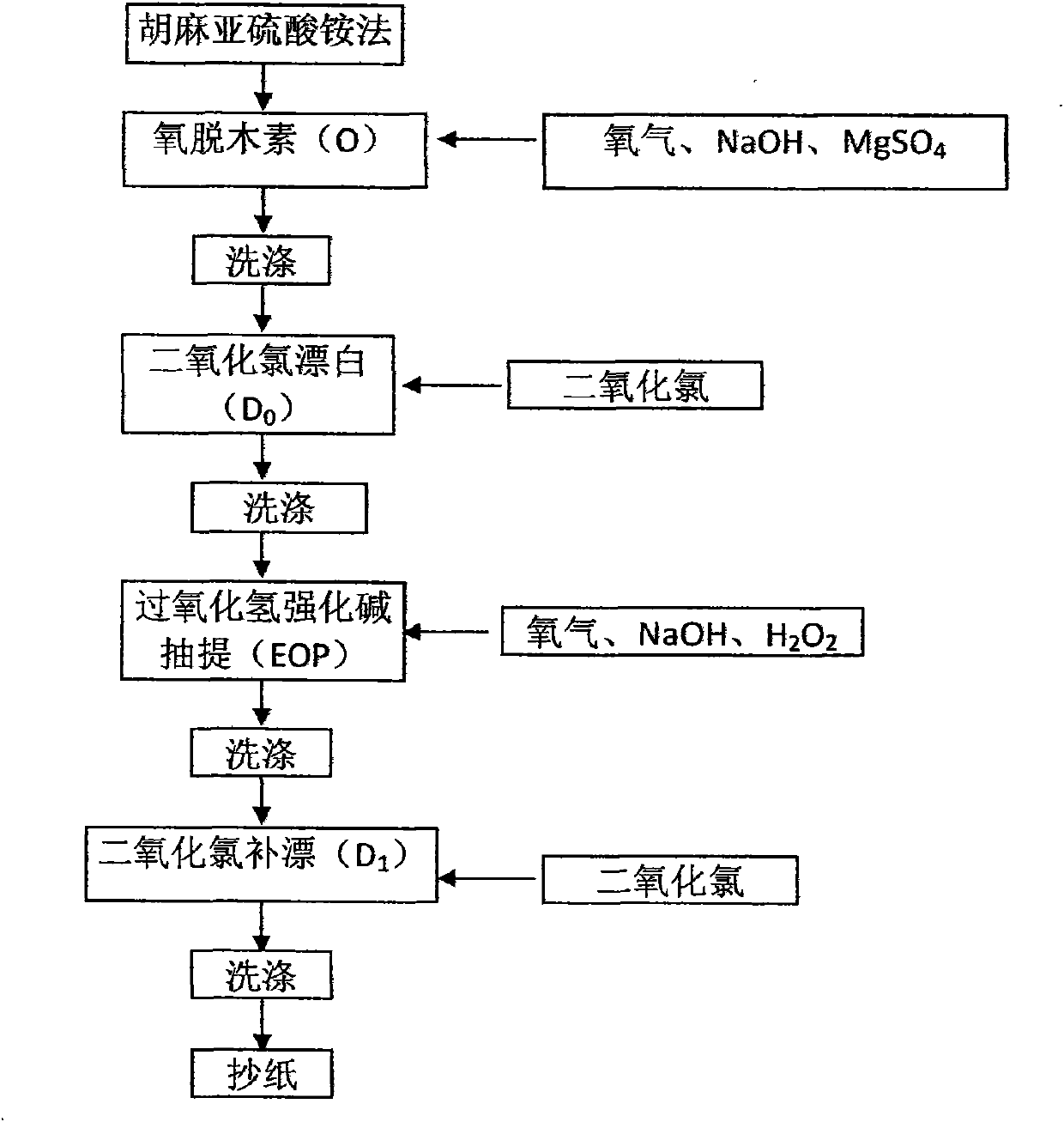

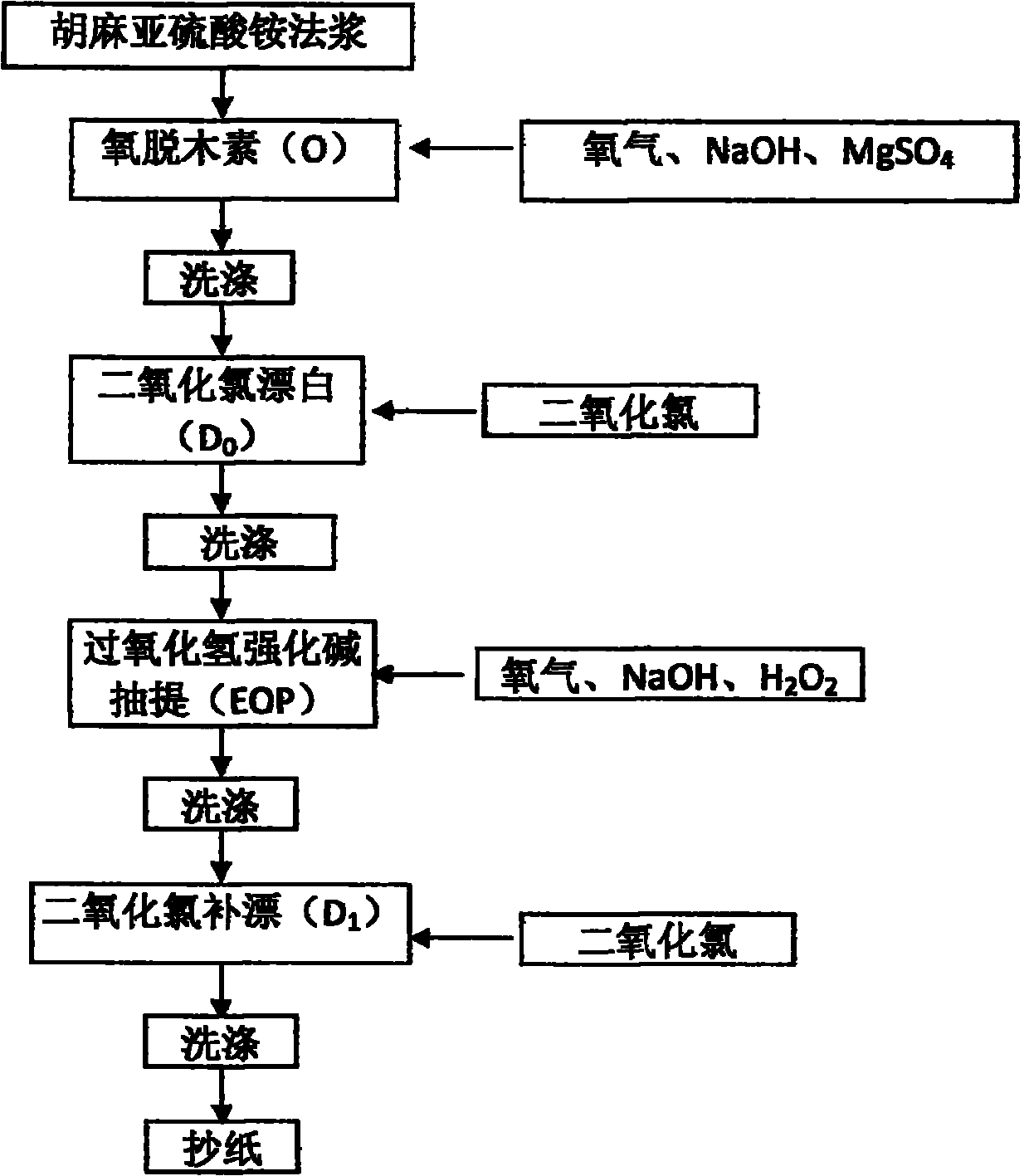

Chlorine dioxide multi-step bleaching method of linseed pulp

A technology of chlorine dioxide and flax pulp, which is applied in the field of pulp bleaching, can solve problems such as environmental hazards, large requirements, and changes, and achieve the effects of improving whiteness, reducing damage, and promoting lignin removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Oxygen delignification section (O): The flax pulp cooked by ammonium sulfite method, washed and screened is mixed with alkali and magnesium sulfate through a medium-concentration mixer, and sent to the medium-concentration oxygen delignification system. The concentration is about 12%; based on the dry pulp mass, the amount of NaOH is 1.8%, MgSO 4 The dosage is 0.1%, the reaction time is 90min, the reaction temperature is 90-95℃, and the oxygen pressure is 0.69MPa;

[0031] 2. Chlorine dioxide bleaching section (D 0 ): After oxygen delignified flax pulp was washed, it was mixed with ClO 2 Mix and enter the chlorine dioxide bleaching tower, the pulp fiber concentration is about 12%, the reaction temperature is 85°C, and the reaction time is 120min; based on the dry pulp mass, the amount of chlorine dioxide is 3.5%, and the final pH value is controlled to be 2.5;

[0032] 3. Oxygen and hydrogen peroxide enhanced alkali extraction section (EOP): after D 0 The flax pul...

Embodiment 2

[0037] 1. Oxygen delignification section (O): The flax pulp cooked by ammonium sulfite method, washed and screened is mixed with alkali and magnesium sulfate through a medium-concentration mixer, and sent to the medium-concentration oxygen delignification system. The concentration is about 12%; based on the dry pulp mass, the amount of NaOH is 2.5%, MgSO 4 Dosage 0.1%, reaction time 90min, oxygen pressure 0.69MPa;

[0038] 2. Chlorine dioxide bleaching section (D 0 ): After oxygen delignified flax pulp was washed, it was mixed with ClO 2 Mix and enter the chlorine dioxide bleaching tower, the pulp fiber concentration is about 12%; based on the dry pulp mass, the chlorine dioxide dosage is 3.0%, the reaction temperature is 95°C, the reaction time is 160min, and the final pH value is controlled to be 2.5;

[0039] 3. Oxygen and hydrogen peroxide enhanced alkali extraction section (EOP): after D 0 After washing the flax pulp in the bleaching section, carry out alkali extractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com