Dye-sensitized nanocrystalline titanium dioxide photo anode and preparation method and application

A technology of titanium dioxide and dye sensitization, applied in the field of photoanode, can solve the problems of unfavorable photoelectric conversion efficiency of batteries and weak absorption of visible light, and achieve the effects of improving photoelectric conversion efficiency of batteries, increasing the probability of absorption and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

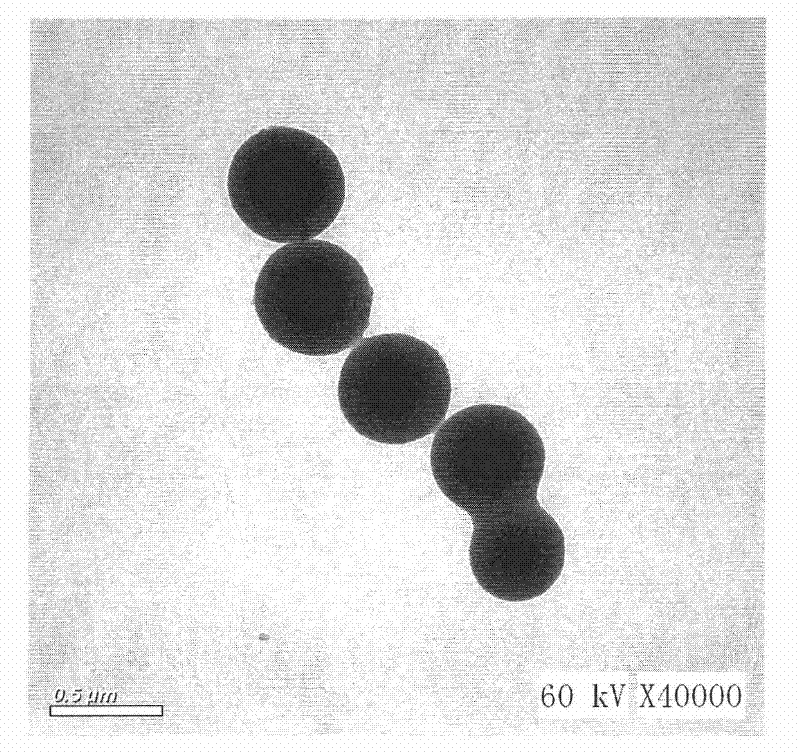

[0026] Embodiment 1: 300nm carbon sphere (see figure 1 shown) obtained from 1M glucose for 4 h at 180°C by hydrothermal treatment. Rotate and separate, dry in an oven at 60 ° C for 12 hours, then dissolve 0.3 g of the carbon spheres in distilled water (the concentration of the colloidal carbon sphere solution is 0.04 g / ml), and then mix with the titanium dioxide slurry prepared by the colloidal gel method after high-power ultrasound (the slurry concentration is 0.082g / ml, containing 2g of titanium dioxide nanoparticles) blended, and then stirred for 1 hour, and then coated on the conductive glass with a film thickness of about 12 μm. The conductive glass coated with the film was calcined in a muffle furnace at 450° C. for 2 hours to obtain the photoanode of the dye-sensitized nanocrystalline solar cell. The photoanode was soaked in a concentration of 5×10 -4 mol / L N3 solution for 24h, the photoanode is fully sensitized by the dye. Then the photoanode was docked with the pla...

Embodiment 2

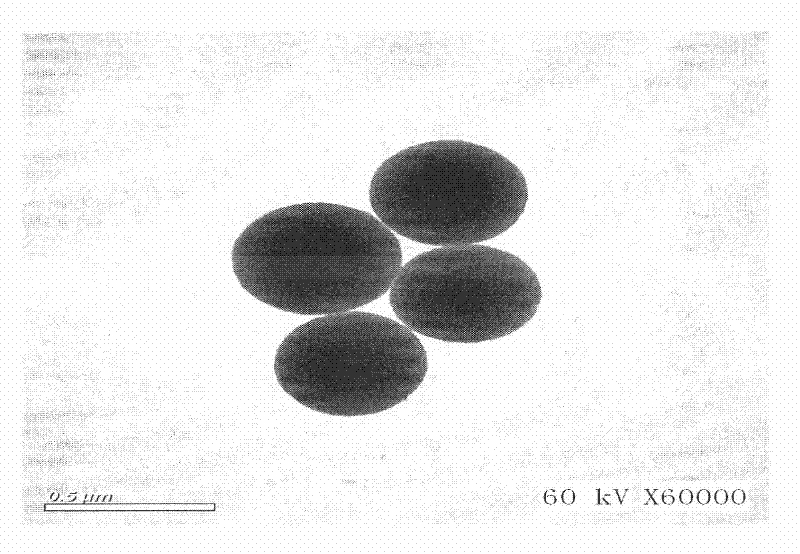

[0027] Embodiment 2: 500nm carbon spheres (see figure 2 shown) was obtained by 0.75M glucose for 8h, 180°C hydrothermally. Rotate and separate, dry in an oven at 60 ° C for 12 hours, then dissolve 0.3 g of the carbon spheres in distilled water (the concentration of the colloidal carbon sphere solution is 0.035 g / ml), and then mix with the titanium dioxide slurry prepared by the colloidal gel method after high-power ultrasound (slurry concentration is 0.085g / ml, containing 1.8g of titanium dioxide nanoparticles), and then stirred for 1h, then coated on the conductive glass, the film thickness is about 12μm. The conductive glass coated with the film was calcined in a muffle furnace at 450° C. for 2 hours to obtain the photoanode of the dye-sensitized nanocrystalline solar cell. There are many porous structures left on the surface, such as Figure 4 shown. The photoanode was soaked in a concentration of 5×10 -4 mol / L N3 solution for 24h, the photoanode is fully sensitized by...

Embodiment 3

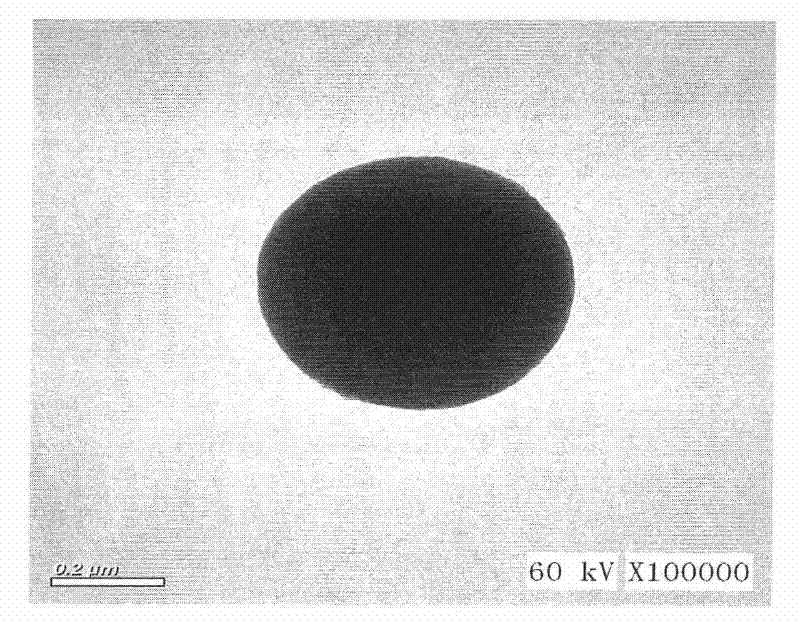

[0028] Embodiment 3: 700nm carbon sphere (see image 3 shown) was obtained by hydrothermal treatment at 180° C. for 8 h with 1 M glucose. Rotate and separate, dry in an oven at 60 ° C for 12 hours, then dissolve 0.3 g of the carbon spheres in distilled water (the concentration of the colloidal carbon sphere solution is 0.045 g / ml), and mix with the titanium dioxide slurry prepared by the colloidal gel method after high-power ultrasound (slurry concentration is 0.078g / ml, containing 1.8g of titanium dioxide nanoparticles), and then stirred for 1h, then coated on the conductive glass, the film thickness is about 12μm. The conductive glass coated with the film was calcined in a muffle furnace at 450° C. for 2 hours to obtain the photoanode of the dye-sensitized nanocrystalline solar cell. The photoanode was soaked in a concentration of 5×10 -4 mol / L N3 solution for 24h, the photoanode is fully sensitized by the dye. Then the photoanode was docked with the platinum counter elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com