Auricularia auricular composition and auricularia auricula chewable tablets prepared from same

A kind of black fungus and chewable tablet technology, which is applied in the direction of drug combination, anhydride/acid/halide active ingredients, organic active ingredients, etc., can solve the problems of the preparation process and quality gap in the variety of traditional Chinese medicine chewable tablets, and achieve low cost and reduced Side effects, the effect of high crushing fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

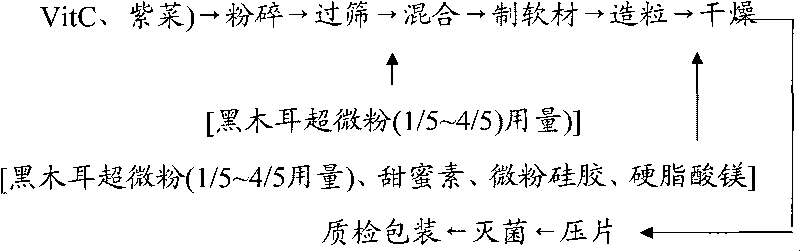

Method used

Image

Examples

Embodiment 1

[0075] 1 Materials and reagents

[0076] Black fungus (choose black fungus from Lishui, code AA1; black fungus from Zhejiang, code AA2; northeast China, code AA3; northeast autumn fungus, code AA4; Zhejiang black fungus, code AA5; Shaanxi black fungus, No. AA6; black fungus produced in Northeast China, No. AA7); absolute ethanol, concentrated sulfuric acid, glucose, phenol ferrous amine sulfate [FeNH 4 (SO 4 ) 2 12H 2 O], 1,10-phenanthroline (C 12 h 8 N 2 ·H 2 O), hydroxylamine hydrochloride, concentrated nitric acid, and anhydrous sodium acetate were all analytically pure.

[0077] 2 experimental equipment

[0078] UV-2000 ultraviolet spectrophotometer; HMB-701 ultrafine pulverizer; HELDS / BF laser particle size analyzer; RE-52A rotary evaporator; WVD-01 microwave vacuum drying oven.

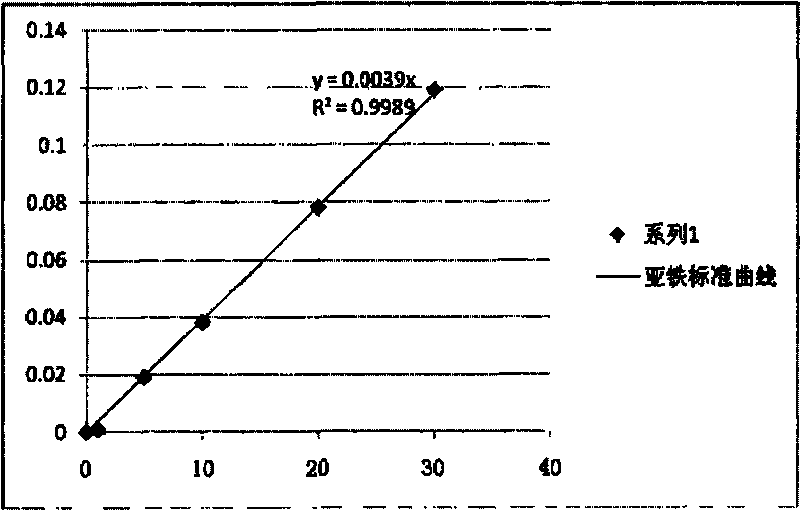

[0079] 3 Experimental methods and results

[0080] 3.1 Black fungus crushing process

[0081] Get the black fungus of 200g, after ordinary mechanical coarse pulverization, sieve with ...

Embodiment 2

[0122] Example 2: Effects of Black Fungus Particle Size on Sensory and Iron Dissolution of Chewable Tablets

[0123] Prepare black fungus chewable tablets according to the preparation process of 3.5 chewable tablets, the difference is that the raw material black fungus superfine powder 27g is changed to black fungus powder that has been coarsely crushed by ordinary machinery and passed through a 40-mesh standard sieve, and other conditions and operations are the same as in Example 1 Step, the black fungus chewable tablet that makes is done the dissolution test of iron in the chewable tablet according to YY / T 0188.10-1995, adopts step (3) in 3.2 to measure the total iron content of dissolution. Table 2 shows the comparison results between ordinary mechanically crushed black fungus powder (through a 40-mesh sieve) and ultra-finely crushed black fungus powder.

[0124] Table 2 Effect of particle size of black fungus on sensory and iron dissolution of chewable tablets

[0125] ...

Embodiment 3~6

[0127] Examples 3-6: Determination of the addition ratio of black fungus superfine powder and seaweed powder

[0128] Change the process of 3.5.1, other steps are the same as in Example 1, the larger the proportion of black fungus superfine powder (AASP) and seaweed powder (PP) in the formula, the higher the nutritional value, but also need to consider chewable tablets The molding effect and the need for taste adjustment. The addition amount of superfine powder of black fungus and seaweed powder was changed, and the amount of other raw materials was kept unchanged. Tablet 3 was used for the tabletting test.

[0129] Table 3 Tablet test results of different proportions of black fungus superfine powder and seaweed powder

[0130]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area mean particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com