Preparation method of graft copolymer of nano cellulose and aliphatic polyester

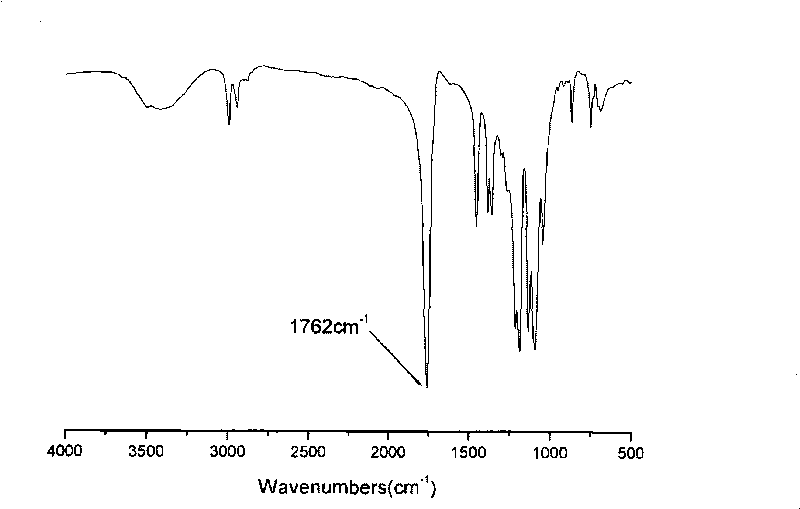

A technology of nano-cellulose and aliphatic polyester, which is applied in the field of polymer materials, can solve the problems of poor compatibility of blending systems, and achieve the effects of good compatibility, plasticity and processability, and alkali and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

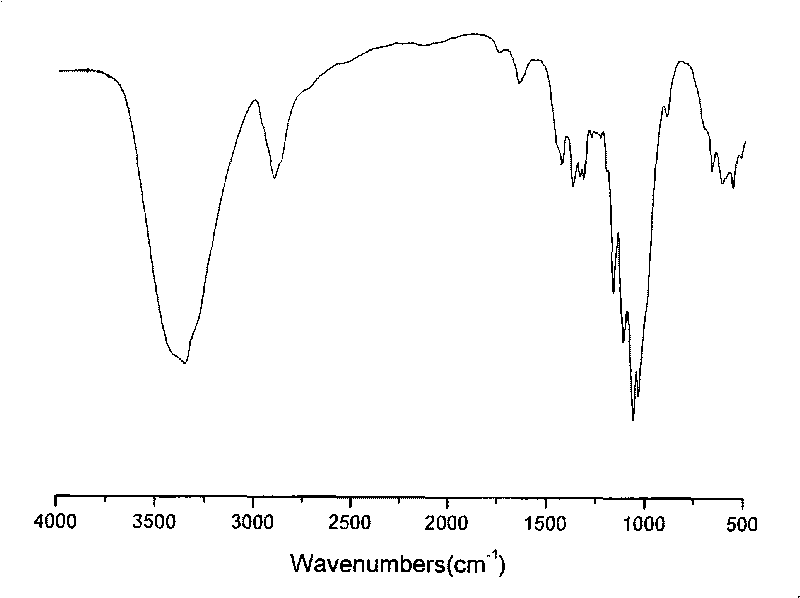

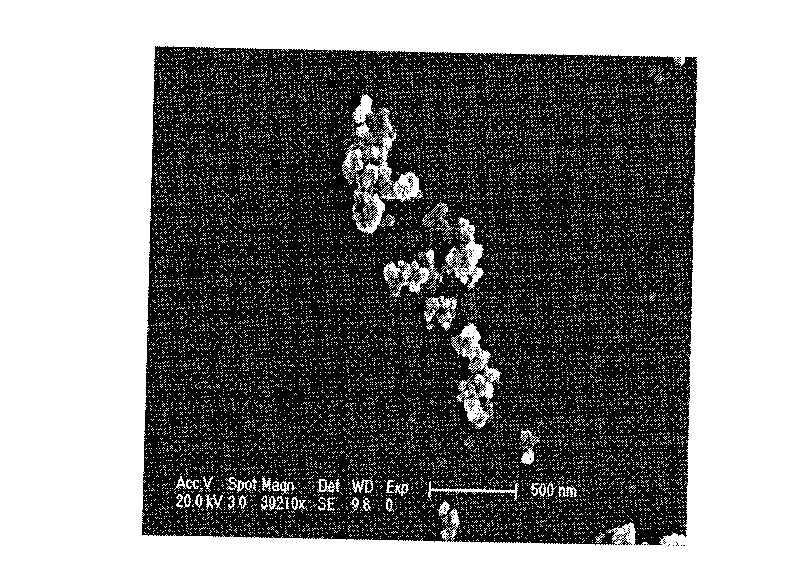

[0023] Preparation of nanocellulose. Disperse 10 grams of cellulose in 100 grams of 65% sulfuric acid aqueous solution, and stir and acidify at room temperature for 48 hours. Then centrifuge to collect the solid, wash the solid with distilled water until neutral, and freeze-dry to obtain nanocellulose. The size distribution of nanocellulose is 80-200nm.

Embodiment 2

[0025] In embodiment 1, replace sulfuric acid aqueous solution with hydrochloric acid aqueous solution, test procedure and method are identical with embodiment 1. The obtained nanocellulose has a size distribution of 80-200 nm.

Embodiment 3

[0027] In embodiment 1, room temperature is changed into 60 ℃, and test procedure and method are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size distribution | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com