Silicate blue fluorescent powder for white-light LED and preparation method thereof

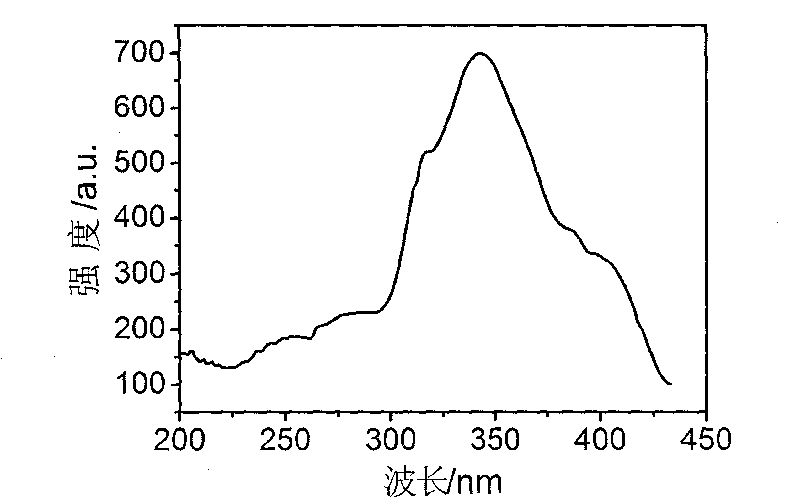

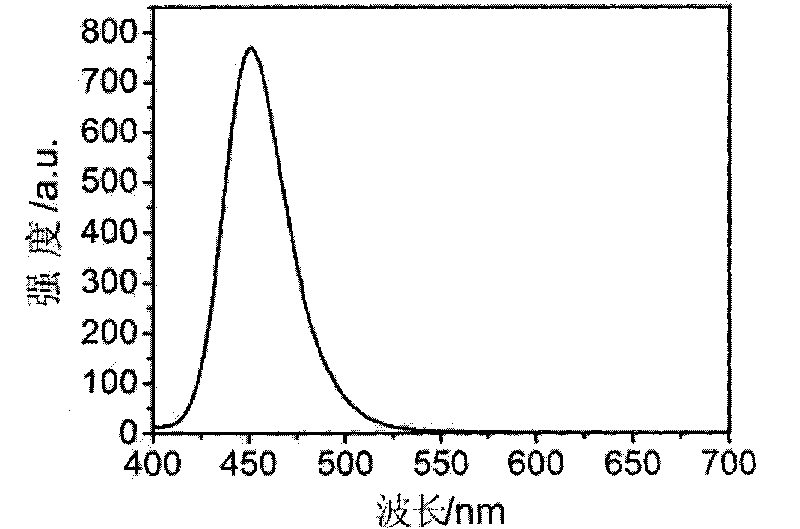

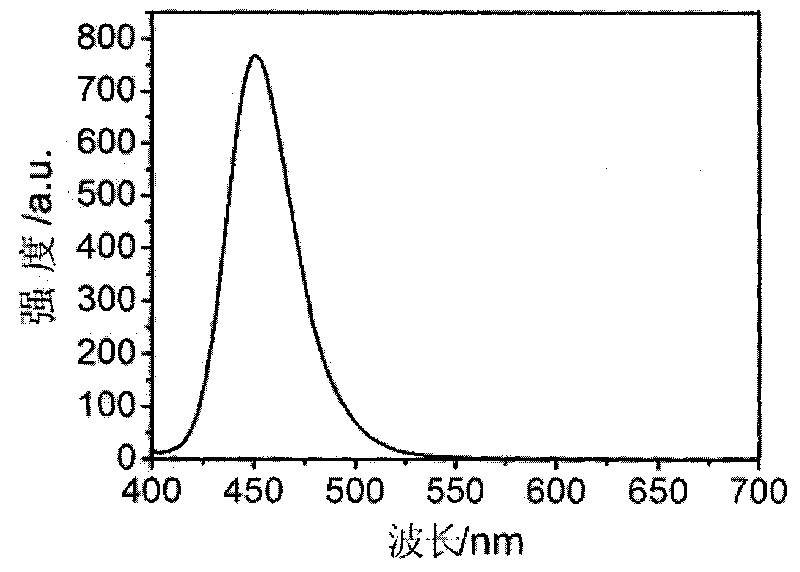

A blue phosphor, silicate technology, applied in chemical instruments and methods, luminescent materials, the use of gas discharge lamps, etc., can solve the problem of low luminous efficiency of blue phosphors, easy absorption by red and green phosphors, Affecting LED luminous performance and other issues, achieving the effects of high luminous intensity, good chemical stability and thermal stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to the chemical formula Ca 0.98 SiO 3 :0.02Eu 2+ The stoichiometric ratio of each element in the formula is weighed CaO (A.R.) 0.98mol, SiO 2 (A.R.)1mol and Eu 2 o 3 (99.99%) 0.01mol; Then take by weighing the flux H of 0.5wt% of the total drug mass 2 BO 3 ; CaO, SiO 2 and H 2 BO 3 After fully mixing, place it in a muffle furnace for calcination at a temperature of 1500°C for 3 hours; weigh the Eu 2 o 3 After mixing evenly with the calcined product, calcining in a reducing atmosphere provided by activated carbon powder combustion, the calcining temperature is 1200 ° C, and the time is 4 hours; the above product is ground, washed, dried, and sieved to obtain the target product.

Embodiment 2

[0022] According to the chemical formula Ca 0.96 SiO 3 :0.04Eu 2+ The stoichiometric ratio of the elements in the 3 (A.R.)0.96mol, H 2 SiO 3 (A.R.)1mol and Eu 2 o 3 (99.99%) 0.02mol; Take by weighing the flux NH of 1.6wt% of the above drug gross mass again 4 HF 2 ; the CaCO 3 、H 2 SiO 3 and NH 4 HF 2 After fully mixing, place it in a muffle furnace for calcination, the calcination temperature is 1300°C, and the time is 5 hours; the weighed Eu 2 o 3 After mixing evenly with the calcined product, calcining in a reducing atmosphere provided by nitrogen / hydrogen mixed gas, the calcining temperature is 1300°C, and the time is 3 hours; the above product is ground, washed, dried, and sieved to obtain the target product.

Embodiment 3

[0024] According to the chemical formula Ca 0.94 SiO 3 :0.06Eu 2+ The stoichiometric ratio of each element in , respectively weighed CaO (A.R.) 0.94mol, SiO 2 (A.R.)1mol and Eu 2 o 3 (99.99%) 0.03mol; Then take by weighing the flux LiCO of 0.8wt% of the total mass of the above medicines 3 ; CaO, SiO 2 and LiCO 3 After fully mixing, put it in a muffle furnace for calcination, the calcination temperature is 1400°C, and the time is 4 hours; the weighed Eu 2 o 3 After mixing evenly with the calcined product, calcining in a reducing atmosphere provided by activated carbon powder combustion, the calcining temperature is 1400 ° C, and the time is 2 hours; the above product is ground, washed, dried, and sieved to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com