Method for preparing L (+) potassium hydrogen tartrate

A technology of potassium hydrogen tartrate and potassium tartrate, which is applied in the field of preparation of L potassium hydrogen tartrate, can solve the problems of high cost and many solid wastes, and achieve the effect of saving energy costs and reducing the discharge of waste water and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of immobilized cell particles

[0021] Slant culture: Nocardia tartancans were inoculated in the slant culture medium and cultured at 30° C. for 24 hours. The culture is as follows: yeast powder 3g / L, peptone 5g / L, glucose 10g / L, agar 20g / L, cultured in a culture medium with a natural pH value.

[0022] Seed culture and fermentation: Both the seed and the fermentation medium use liquid medium, and the components of the liquid medium are glucose 10g / L, yeast powder 3g / L, ammonium sulfate 3g / L, anhydrous MgSO 4 0.5g / L, K 2 HPO 4 ·3H 2 O 1g / L, KH 2 PO 4 1g / L; use an inoculation needle to take a ring of bacteria from the slant medium and inoculate it into a 250ml Erlenmeyer flask containing 100ml liquid medium, and cultivate it at 30°C and 180r / min for 24 hours to obtain a first-grade seed solution. The primary seed solution was inoculated in a 300L seed tank containing 200L liquid medium with an inoculation amount of 10%, cultivated for 10h a...

Embodiment 2

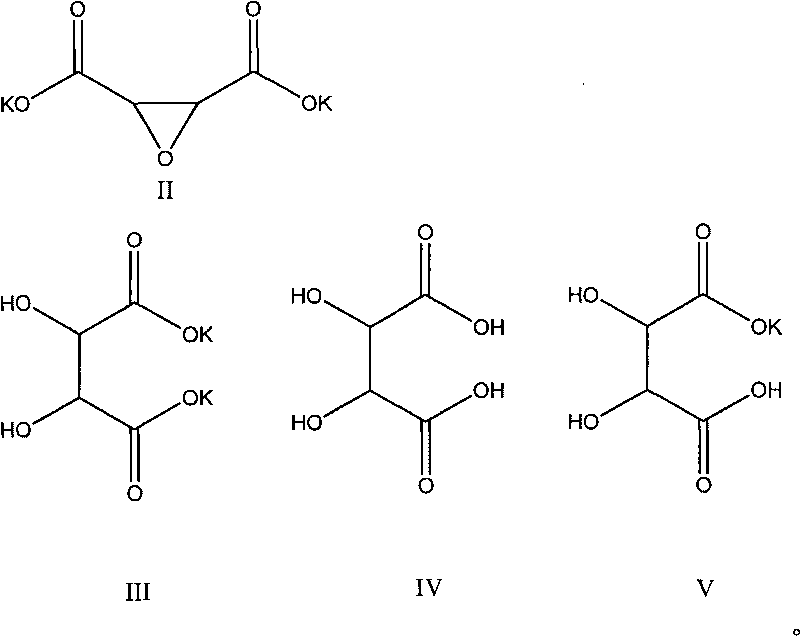

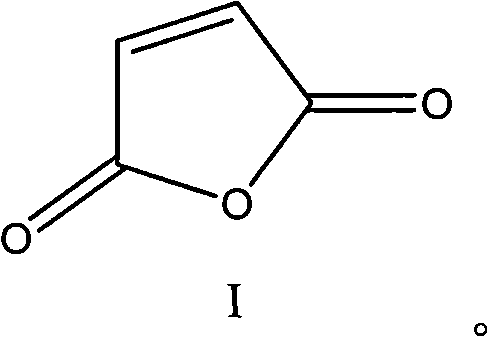

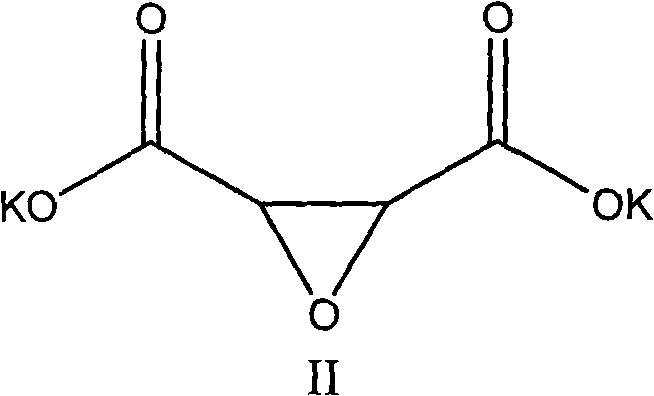

[0027] A. Add 49 grams of water into a 500ML glass reactor, add 98 grams of maleic anhydride, 150 grams of 27.5% hydrogen peroxide, and 1 gram of sodium tungstate, slowly add 116 grams of 48% potassium hydroxide dropwise, and control the temperature at 70 Celsius, reacted for 6 hours, the reaction solution was cooled to room temperature, centrifuged, and the precipitate was taken to obtain 150 grams of potassium epoxy succinate, and the mother liquor could be recycled.

[0028] B. In the reaction vessel, add 80 grams of immobilized cell particles prepared by the method in Example 1, then add water to 150 grams of potassium epoxysuccinate obtained in step A to make 1 L of 0.72mol / L solution, and add it to the reaction vessel , keep warm at 35-37°C, shake on a shaker for 18 hours, filter, the filtrate is potassium tartrate solution, add L(+) tartaric acid to adjust the pH to 3.5, centrifuge, take the precipitate, and obtain 260g of L(+) potassium hydrogen tartrate, the purity 99...

Embodiment 3

[0030] The fermented liquid was prepared according to the method of Example 1, and 5 L of the fermented liquid was centrifuged to obtain 50 grams of fermented thallus, which was used for the immobilization of the thalline, and the wet thalline concentration of the fermented liquid was 10 g / L.

[0031] Take 50 grams of fermented cells obtained by centrifugation and mix them with 100 ml of normal saline, stir evenly to obtain a mixed liquid of cells, keep the temperature at 35-37°C for later use;

[0032] Warm up to 100°C with a volume of 250ml of 3% carrageenan solution, stir and mix evenly, cool down to 45°C, then add the bacterial cell mixture, stir well and drop into 2% potassium chloride aqueous solution to form immobilization Particles, the average diameter of the particles is 2mm, solidified for 2 hours, soaked in 0.5% glutaraldehyde for one hour, washed with normal saline, and obtained 400 grams of strengthened immobilized cell particles. Put the immobilized cells into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com