Process for absorbing and extracting valuable metal ions in leachate of laterite nickel ore by applying immobilized room temperature ionic liquid

A room temperature ionic liquid and valuable metal technology, applied in the direction of improving process efficiency, can solve the problems of complex composition, low recovery rate, and many equipment stages, and achieve high extraction efficiency, short operation time, and simple process operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

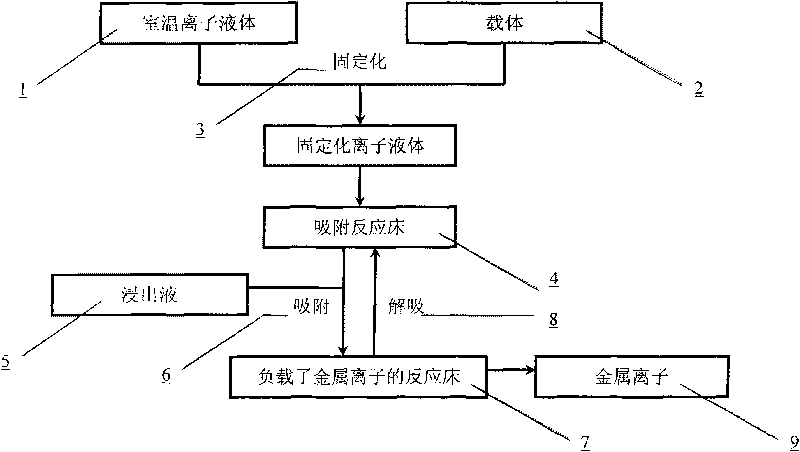

Method used

Image

Examples

Embodiment 1

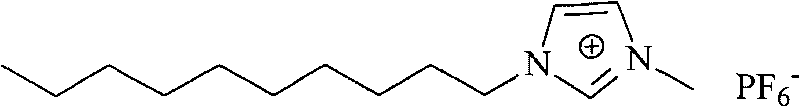

[0036] 1-decyl-3-methylimidazolium hexafluorophosphate is selected and immobilized on the montmorillonite carrier. After 48 hours of treatment, the loading rate can reach 77%.

[0037] Take the acidic leaching solution of nickel-cobalt ore, its pH value is 3.5, and the main component in the leaching solution is Cu 2+ : 3.5g / l; Ni 2+ : 1.2g / l; Co 2+ : 0.6g / l; Fe 2+ : 3.9g / l; Fe3 + : 9.5g / l.

[0038] At room temperature, the leaching solution was dripped into a vertically placed adsorption bed at a flow rate of 5ml / min, and the residual solution was collected at the bottom of the bed. Cycle through 2 times.

[0039] The amount of metal ions adsorbed by the loaded filler in the adsorption bed was analyzed by ultraviolet spectrophotometry. The calculation shows that the metal ion adsorption rates are: Cu 2+ : 70%; Ni 2+ : 81%; Co. 2+ : 84%; Fe 2+ : 55%; Fe3 + : 62%.

[0040] Take out the loaded filler that has adsorbed the metal ions in the adsorption bed, and place i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com