Formation method of silicon oxide film and metal-insulator-metal capacitor

A silicon oxide and thin film technology, applied in metal material coating process, circuits, electrical components, etc., can solve the problems of poor dynamic characteristics of MIM capacitors, improve dynamic characteristics, stabilize capacitance voltage coefficient and capacitance temperature coefficient, and stabilize electric capacity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

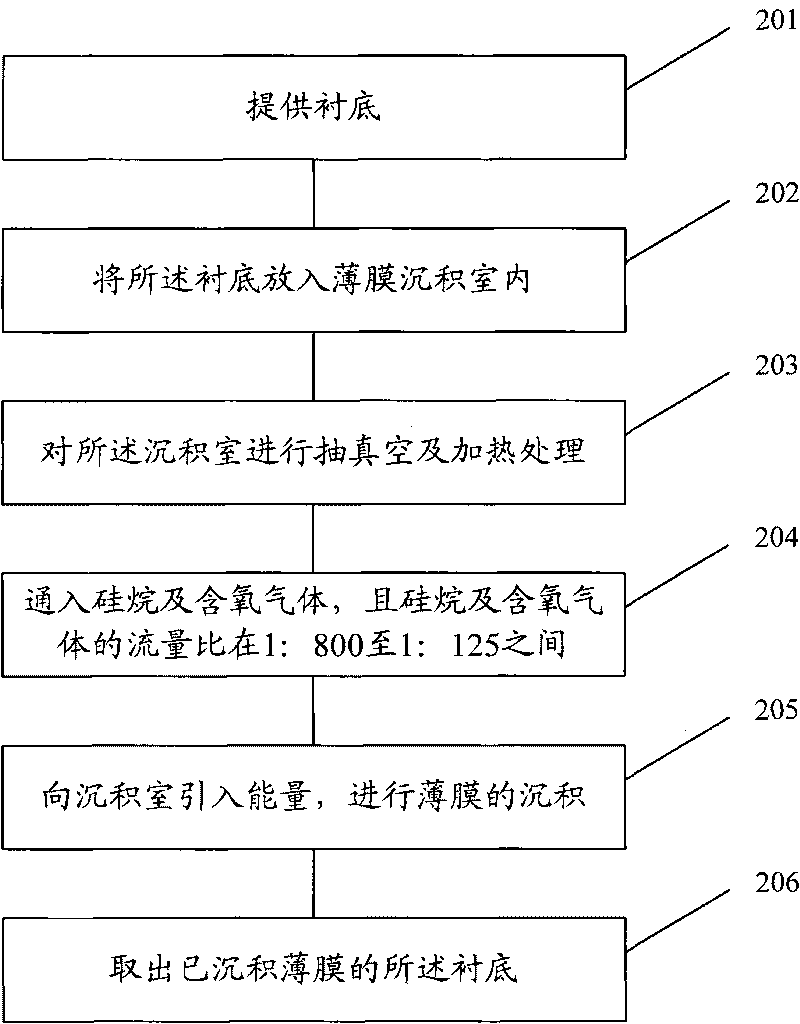

[0066] The first embodiment of the present invention introduces a new method for forming a silicon oxide film, figure 2 for

[0067] The flowchart of the method for forming a silicon oxide film according to the first embodiment of the present invention is combined below figure 2 The first embodiment of the present invention will be described in detail.

[0068] Step 201: providing a substrate.

[0069] The substrate provided in this embodiment may be a simple silicon substrate, or a silicon substrate on which metal oxide semiconductor transistors have been formed, or a substrate on which an underlying metal wiring structure has been formed.

[0070] In other embodiments of the present invention, semiconductor substrates of other materials may also be used, such as germanium substrates, gallium arsenide substrates, and the like.

[0071] Step 202: Put the substrate into a film deposition chamber.

[0072] The film deposition equipment used in this embodiment is PECVD. In ...

no. 2 example

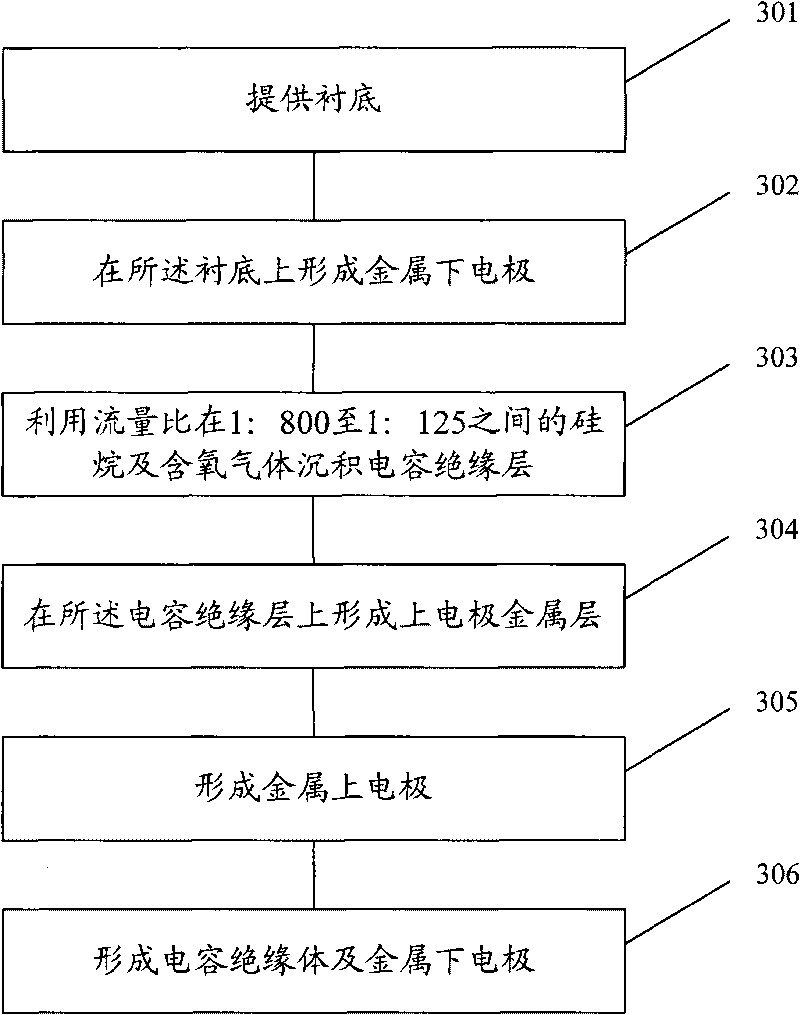

[0090] The second embodiment of the present invention introduces a new method for forming a MIM capacitor, image 3 It is a flowchart of a method for forming a MIM capacitor according to the second embodiment of the present invention, Figure 4 to Figure 10 In order to illustrate the schematic cross-sectional view of the device of the MIM capacitance forming method of the second embodiment of the present invention, the following is combined Figure 3 to Figure 10 The second embodiment of the present invention will be described in detail.

[0091] Step 301: Provide a substrate.

[0092] The substrate provided in this embodiment may be a silicon substrate on which a metal oxide semiconductor transistor has been formed, or a substrate on which an underlying metal wiring structure has been formed.

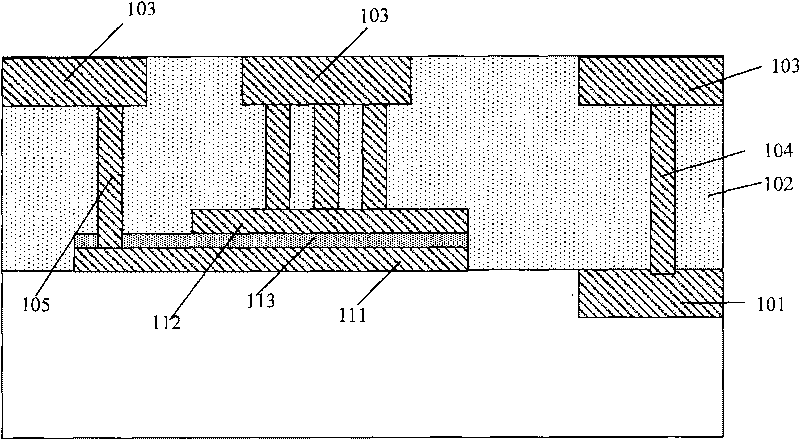

[0093] Figure 4 is a schematic cross-sectional view of the substrate provided in the second embodiment of the present invention, such as Figure 4 As shown, the underlying conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com