Rare earth alloy of anode plate grid for lead-acid storage battery

A technology of lead-acid batteries and rare earth alloys, which is applied in the direction of electrode carriers/collectors, etc., can solve the problems of not being very suitable and the loss of reproducibility of the action of rare earth elements, etc., to achieve better conductivity, improve capacity preservation, and reduce early Effects of Capacity Fade and Thermal Runaway Bulging Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

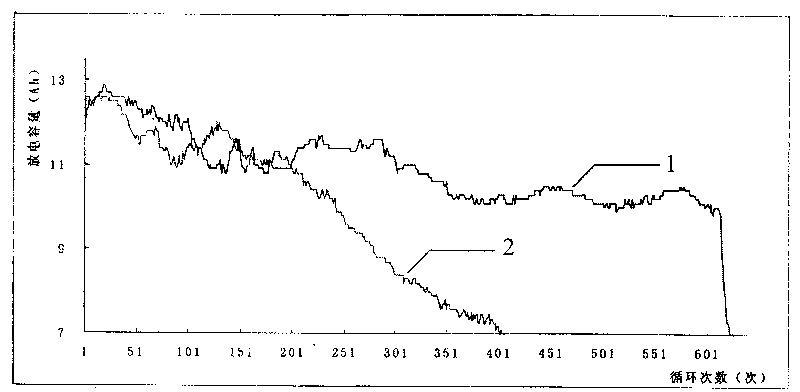

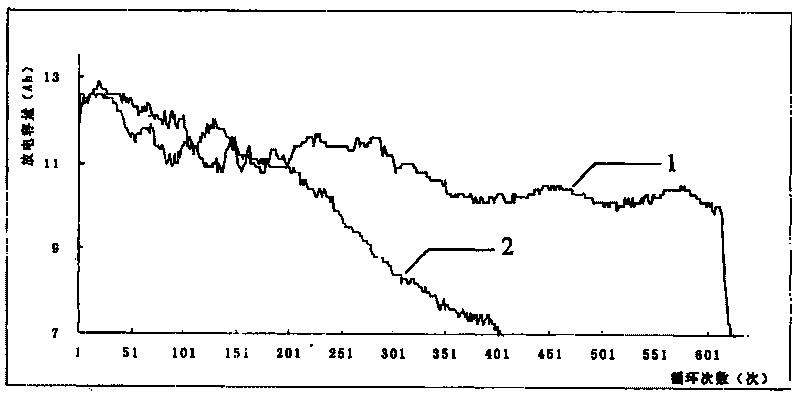

Image

Examples

example 1

[0010] 1.2 The battery prepared by the above two alloys in accordance with the capacity preservation capacity test of the "electric help vehicle sealing lead-acid battery GB22199-2008"., Increase the capacity preservation capacity of the battery from 88 % to 93 %.

[0011] Example 2: Select the percentage of each component as follows: 锑: 1.4 %, arsenic: 0.25 %, tin: 0.21 %, selenium: 0.01 %, sulfur: 0.005 %, copper: 0.048 %, the rest are preparation to ordinary low 锑 锑Metal C; then select the same mass percentage of the same mass, arsenic, tin, tin, selenium, sulfur, and copper according to the above quality percentage, and adds a pupae of 0.18 % of the mass of 0.09 %.Use alloy C and D to make positive plate grills and assemble the 12V10AH battery for electric vehicles with 8 vehicles in the 7 -chip structure of each one -cell neutral pole. The negative electrode still uses the universal negative lead calcium alloy in the market.

example 2

[0012] 2.1 By discharged to 10.5V in accordance with the constant current 5A, then the constant voltage 14.4V, the current limit of 1.8A charging for 10 hours, for a complete cycle, the life cycle test of 100 % discharge depth.When %, the life span is terminated.The test results reproduced the results of the example 1 again.

[0013] 2.2 For the two batteries prepared in different alloys in this example, the capacity preservation capacity test is performed in accordance with the "electric help vehicle sealing lead-acid battery GB22199-2008".The capacity preservation capacity is increased by about 5 % to 7 %; the test results reproduce the results of the example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com